News & Press Release

March 6th 2024 | Professor Till Clausmeyer becomes a new member of the Forming Technology Working Group (AGU)

The members of the Forming Technology Working Group (AGU) accepted Professor Till Clausmeyer as a new member at their working meeting on March 6, 2024 at the TU Bergakademie Freiberg.

The AGU pursues the goal of scientifically based technical and economic development of forming technology. Its members represent research-intensive universities and non-university institutions. In future, Chemnitz will be actively represented in the AGU with two members.

Professor Birgit Awiszus was Head of the Chair of Virtual Production Engineering at Chemnitz University of Technology until 30.09.2023 and has been successfully involved in the network, which was founded in 1974, since 2001. With his appointment to the Chair of Forming Technology at Chemnitz University of Technology, Professor Clausmeyer has taken over the teaching and research activities of the Chair of Virtual Production Technology (provisional head until 29.2.2024: Dr. Carolin Binotsch). The Chair of Forming Technology also includes the teaching and research activities of the Chair of Forming and Joining, which was most recently headed by Dr. Andreas Kunke on an interim basis.

On March 1, 2024, the symbolic handover of the baton from the former professorships to Professor Clausmeyer took place during a ceremony. Birgit Awiszus and Till Clausmeyer are looking forward to working together at Chemnitz University of Technology and their joint representation in the AGU.

March 1st 2024 | Press release from TUC | Uni Aktuell

-

Personalia

Neue Berufung an die Universität

Neue Berufung an die UniversitätZum 1. März 2024 wurde an der TU Chemnitz ein neuer Professor berufen – Till Clausmeyer leitet zukünftig die Professur Umformtechnik

Dezember 5th 2023 | Press release from TUC | Uni Aktuell

-

Ehrungen

Goldene und silberne Lorbeeren für herausragende Dissertationen

Goldene und silberne Lorbeeren für herausragende DissertationenAlexander Graf und Robert Laue von der Fakultät für Maschinenbau der TU Chemnitz wurden mit dem „Sächsischen Preis für Umformtechnik“ geehrt

October 17th 2023 | Press release from TUC | Uni Aktuell

-

Personalia

Sie setzte Akzente im Maschinenbau und ist weiterhin als Gutachterin gefragt

Sie setzte Akzente im Maschinenbau und ist weiterhin als Gutachterin gefragtProf. Dr. Birgit Awiszus geht nach langjähriger Lehr- und Forschungstätigkeit an der TU Chemnitz in den Ruhestand – von Stillstand kann aber keine Rede sein

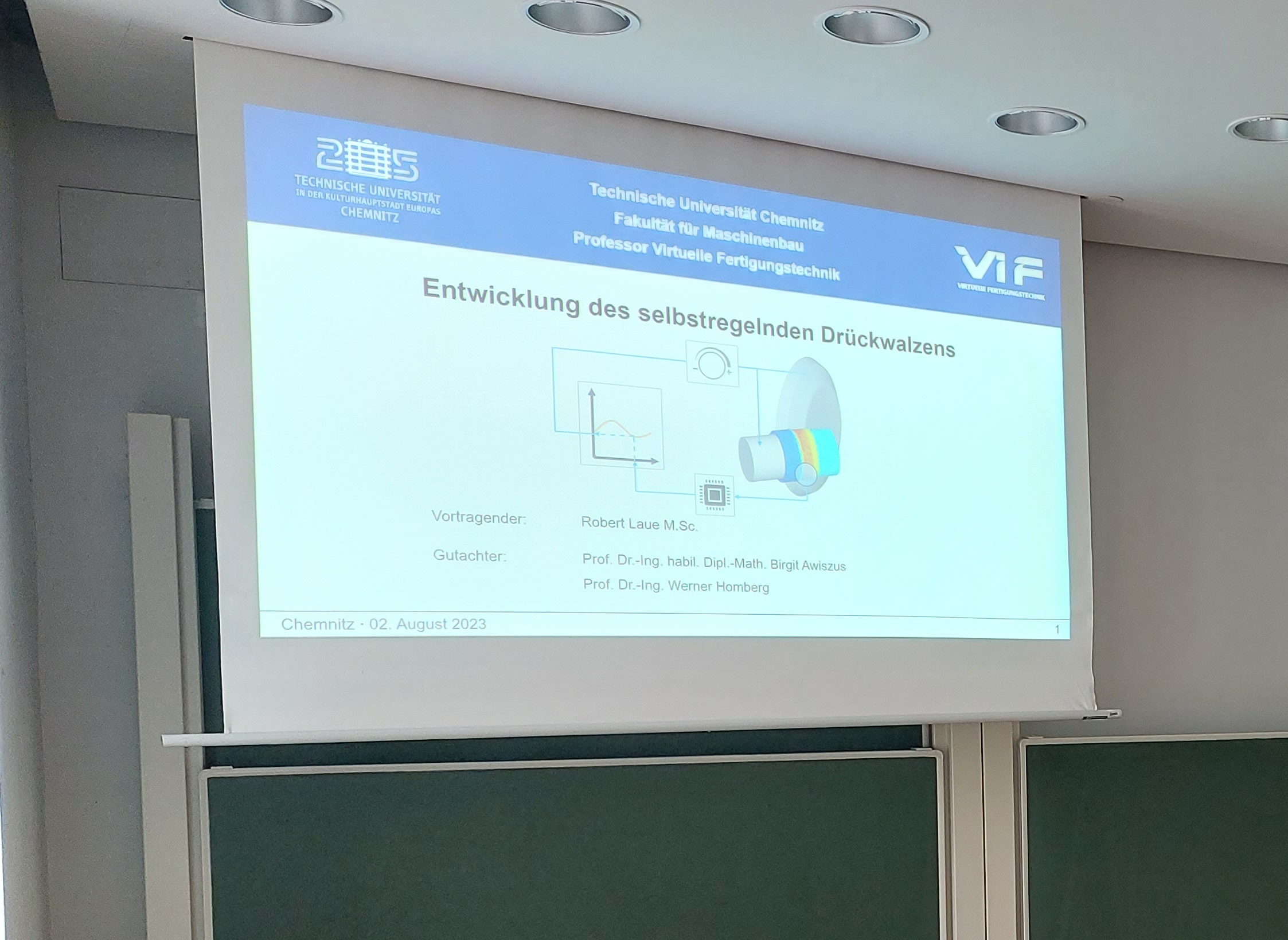

August 2th 2023 | Doctorate successfully completed

-

Impressions | Photo: Professorship ViF -

Impressions | Photo: Professorship ViF -

Impressions | Photo: Professorship ViF -

Impressions | Photo: Professorship ViF

On 2 August 2023, Mr Robert Laue successfully defended his dissertation on the topic of "Development of self-regulating flow-forming" and received the grade "summa cum laude" (very good with distinction) for it.

The development of self-regulating flow-forming makes a decisive contribution to increasing the productivity of this forming process. Due to the fact that flow-formed components can be produced independently of the disturbance size, rejects and process start-up times can be reduced. A further decisive advantage of self-regulation is that the requirements (delivery tolerances) for the semi-finished product used can be reduced, which significantly increases the economic attractiveness of the process.

The dissertation was written as part of his research activities at Chemnitz University of Technology.

We congratulate our colleague Dr.-Ing. Robert Laue on the successful completion of his doctorate.

April 21th 2023 | Doctorate successfully completed

-

Impressions | Photo: Professorship ViF -

Impressions | Photo: Professorship ViF -

Impressions | Photo: Professorship ViF -

Impressions | Photo: Professorship ViF

Martin Heckmann successfully defended his dissertation on 21 April 2023 on the topic of "Stress-based approach to increasing the buckling stiffness of car body outer skin parts". The thesis was written in cooperation with Heilbronn University.

The result of the work is the realisation that the buckling stiffness of car body outer skin parts can be increased specifically and significantly by elastic prestressing. Consequently, thinner sheet metal can be used. The presented work thus contributes to lightweight automotive construction and thus to the improvement of industrial resource efficiency.

We congratulate Dr.-Ing. Martin Heckmann on his successfully completed doctorate.

March 31th 2023 | Press release from TUC | Uni Aktuell

-

Veranstaltungen

Fakultät für Maschinenbau organisiert interne Konferenz zum Thema Wasserstoff

Fakultät für Maschinenbau organisiert interne Konferenz zum Thema WasserstoffWasserstoff wird ein Profilschwerpunkt der Fakultät - Zusammenarbeit zwischen den Professuren auf diesem Arbeitsgebiet soll intensiviert werden

March 29th and 30th 2023 | 23th Materials Technology Colloquium (WTK) Chemnitz

-

Impressions of the lecture | Photo: WTK -

Impressions of the lecture | Photo: WTK -

Impressions of the lecture | Photo: WTK -

Impressions of the lecture | Photo: WTK

The Institute of Materials Science and Engineering (IWW) at Chemnitz University of Technology cordially invited participants to the 23rd Materials Engineering Colloquium (WTK). The two-day programme was filled with current research topics from the fields of materials science as well as surface and joining technology and the additional accents such as hydrogen storage and new trends in welding technology.

The Chair of Virtual Production Technology participated in this year's colloquium with a lecture. Sandra Friedrich presented the current research results on the DFG project "Macromechanical model for predicting the susceptibility to acid corrosion and hydrogen embrittlement of austenitic thin sheets and foils after complex forming processes" in her lecture "Numerical mapping of near-surface corrosion susceptibility on cold-rolled austenitic stainless steel 316L".

The paper presented an approach to calculate the corrosion rates by numerical forming simulations for the material 316L (1.4404) after cold rolling. For this purpose, the numerical approach for predicting the microstructure was extended by empirically calibrated models to include the component surface, the microstructure near the surface, the forming-related residual stresses and the roughness. This allows the forming to follow an adapted process route so that these properties can be specifically adjusted and a reduction in the corrosion rate can be achieved.

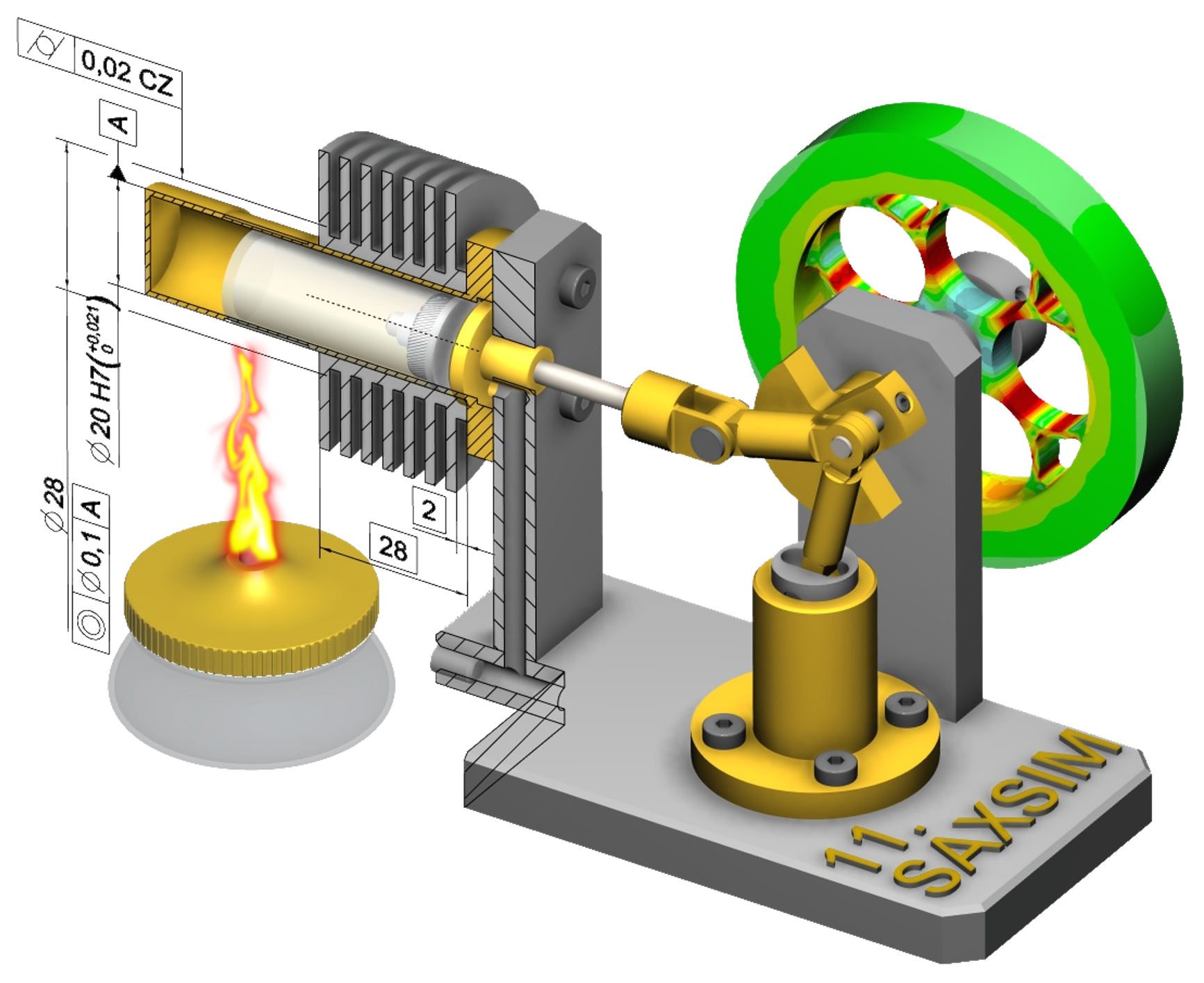

March 7th 2023 | 12th SAXSIM User Meeting

-

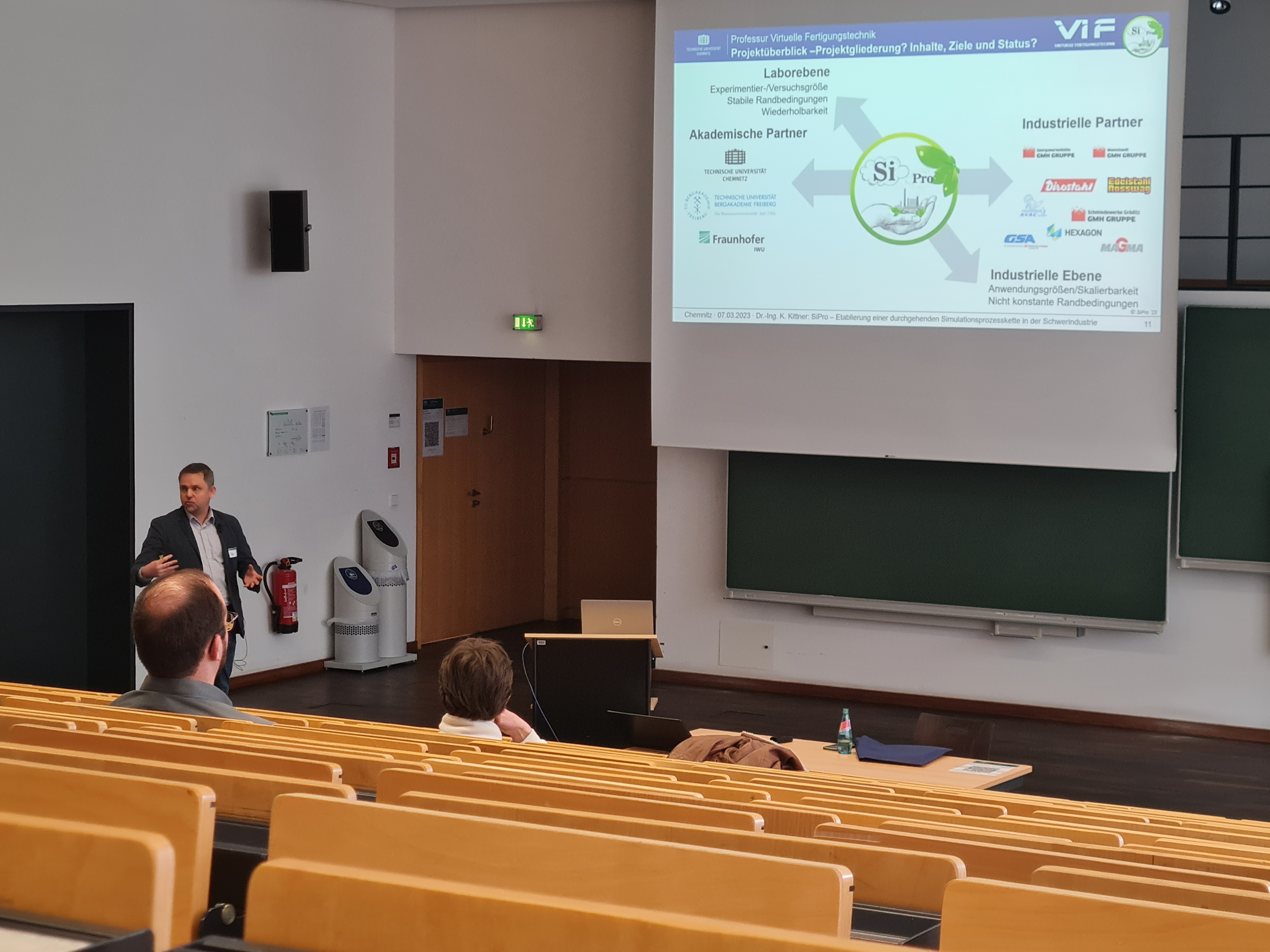

Impressions of the lecture | Photo: Professorship ViF -

Impressions of the lecture | Photo: Professorship ViF

After a three-year break, the 12th SAXSIM (SAXon SImulation Meeting) user meeting was held on 7 March this year. The focus of the meeting is generally the application of simulation in the engineering context, with the main focus on the Finite Element Method (FEM). The aim of the event is to be a mainly regional forum where specialists of the different simulation applications can meet, exchange and discuss. The conference started with an informal "come together" the evening before, this time at the Turmbrauhaus in the centre of Chemnitz.

The Chair of Virtual Production Technology again contributed to the conference this year. Dr. Kai Kittner presented an overview of the BMWK project "SiPro" (simulation-based property design along the combined process chain of forming-forming). Within the presentation, after the motivation, the project, the structure, the contents and the current project status were dealt with in more detail, combined with a few selected work contents.

The members of the professorship are already looking forward to the next SAXSIM user meeting in 2024.

December 7th 2022 | Press release from TUC | Uni Aktuell

-

Personalia

Chemnitzer Maschinenbau-Professorin ist Mitglied im höchsten Gremium der Exzellenzstrategie des Bundes und der Länder

Chemnitzer Maschinenbau-Professorin ist Mitglied im höchsten Gremium der Exzellenzstrategie des Bundes und der LänderGemeinsame Wissenschaftskonferenz und Bundesministerin für Bildung und Forschung haben Prof. Dr. Birgit Awiszus, Inhaberin der Professur Virtuelle Fertigungstechnik, in internationales Expertengremium zur Spitzenforschung berufen

November 7th 2022 | 36. Aachen Steel Colloquium

The 36th Aachen Steel Colloquium - Forming Technology was held on October 26-27, 2022. The event has become one of the most important discussion forums for the steel producing and processing industry in Germany. The scientists of Prof. Awiszus' professorship Virtual Production Engineering also took part. The event focused on presentations on the sustainable design of forming processes. In particular, the challenges to future process design associated with the goal of decarbonization in the manufacture of semi-finished products were discussed. In addition to the successful presentation of the research work by Mr. Robert Laue on property-controlled flow-forming in the digital twin, the ViF scientists used the opportunity for discussions and exchange with other conference participants. Due to the industrial presence at the ASK, it was possible to establish new contacts outside the usual research environment and to build up cross-sectional networks.

September 13th 2022 | Press release from TUC | Uni Aktuell

-

Alumni

Goldene Diplome für Maschinenbau-Absolventen

Goldene Diplome für Maschinenbau-AbsolventenAbsolventen der Matrikel 1965 kehrten an „ihre“ Fakultät zurück

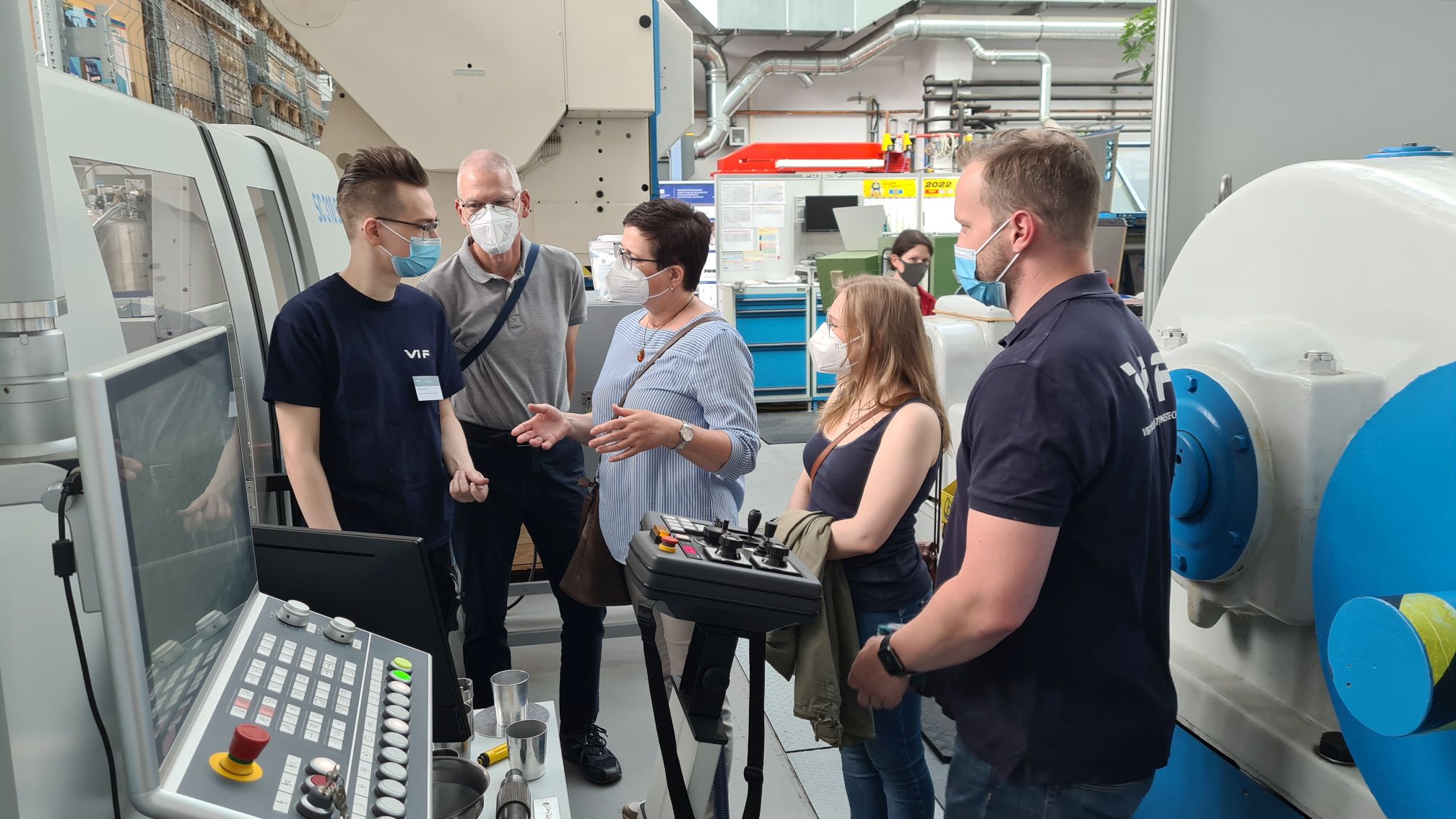

June 27th 2022 | Successful SiPro project meeting

On June 21 and 22, 2022, the project members in the BMWK project "SiPro" met in Chemnitz. For the first time since Corona, the project partners were able to meet in presence and exchange ideas and opinions also in an informal setting. On the first day, with the social evening, the focus was simply on the actual getting together over food and drinks at the Janssen restaurant. The following day, the first biannual project meeting took place. In short excerpts, the status of the SiPro project, the individual work packages and their planning for the next half year were presented. Afterwards, the project partners could visit the experimental area of the Professorship Virtual Production Engineering and inform themselves about further research topics. The next project meeting will take place in Pfinztal at the project partner Rosswag GmbH.

Further information about the project will be given in the article of the TUC Press Office (only in German).

June 13th 2022 | Spinning parts from ViF at the University Information Day - June 11th 2022

-

Robert Laue (m.) explains the details of spinning parts to interested visitors | Photo: Dr. Carolin Binotsch -

Martin Reichardt (l.) reports first-hand about studying mechanical engineering at the TU Chemnitz | Photo: Dr. Carolin Binotsch -

Even the very young potential students were able to get their first taste of forming air | Photo: Dr. Carolin Binotsch

At the University Information Day "TUCdiscover" on June 11, 2022, the Department of Mechanical Engineering was able to give an insight into the world of technology at 17 stations of the "Mechanical Engineering Experience Road". At the booth of the Professorship Virtual Production Engineering, interested visitors had the opportunity to make their own cup out of metal on the modern high-performance spinning machine. In addition, the staff and minor scientists provided information about studying mechanical engineering at TUC as well as insights into current research projects.

Further information about the University Information Day "TUCdiscover" is given in the article of the TUC Press Office (only in German).

June 07th 2022 | FC³ Fuel Cell Conference Chemnitz - May 31st till June 1st 2022

-

Formed biploar plates with a nominal sheet thickness of 0.05 mm | Photo: Dr. Kai Kittner -

Simulation results demonstrated by means of augmented reality | Photo: Dr. Kai Kittner -

Maik Fiedler (l.) and Dr.-Ing. Kai Kittner (r.) of ViF presented the project results at the conference | Photo: Maik Fiedler

Under the motto "Clean drives. Produced efficiently.", the innovation cluster "HZwo - Antrieb für Sachsen" and the Fraunhofer IWU invited participants to Chemnitz for the second time. The aim of the conference is to investigate manufacturing processes around the topic of fuel cells.

The Professorship Virtual Production Engineering (ViF) is also involved with a project within the "HZwo-Cluster" and was represented at the conference with an information booth. The project focuses on manufacturing processes for large-scale production of bipolar plates, which are being investigated at the professorship. The focus of the investigation is on the one hand the production by roll embossing and on the other hand the industrial standard process, deep drawing (embossing). Individual aspects of the work could be followed at the booth. For example, ready-formed biploar plates were available, which attracted great interest from visitors due to their low nominal plate thickness of 0.05 millimeters. With the support of augmented reality, visitors were able to get a closer look at the forming process and forming results by overlaying the components with simulation results. The active tool surfaces and a video showing key aspects of the project were also on display. In the future, we will continue to work on carrying the "spirit" of hydrogen beyond the projects of the "HZwo-Cluster", so that hydrogen will make the contribution we all hope it will, despite the enormous challenges that must be overcome on the way to a hydrogen economy.

December 20th 2021 | Press release from TUC | Uni Aktuell

-

Forschung

Millionen-Förderung für Verbundprojekt zur Erforschung effizienterer Wertschöpfungsketten bei der Herstellung metallischer Produkte

Millionen-Förderung für Verbundprojekt zur Erforschung effizienterer Wertschöpfungsketten bei der Herstellung metallischer ProdukteDas BMWi fördert ein Verbundprojekt unter Leitung der Professur Virtuelle Fertigungstechnik der TU Chemnitz zur Verringerung der Umweltbelastung bei der Herstellung von Metall-Produkten mit rund 3,4 Millionen Euro

September 21st 2020 | Statement in the ZEIT explains "virtual production engineering"

May 29th 2020 | New book published: "Grundlagen der Fertigungstechnik"

The book by Prof. Dr. Birgit Awiszus, Prof. em. Dr. Jürgen Bast, Dr. Thomas Hänel and Dr. Mario Kusch, entitled "Grundlagen der Fertigungstechnik", is available now as eBook and printed version.

The textbook provides the essential foundations of modern processes in manufacturing technology (including primary shaping, forming, cutting, joining, coating, heat treatment processes and additive manufacturing). Not only technical and technological relationships are considered, but also economic and organizational aspects of all components of the manufacturing processes are taken into account. For a better understanding, the basic knowledge is illustrated by practical application examples from various branches of industry. The textbook is ideal for beginners to learn about the essential basics of manufacturing technology as well as for practitioners as a reference book.

Further information can be found on the associated website of the publisher.

February 06th, 2020 | Research team of the TU Chemnitz starts with project in SPP 2183

-

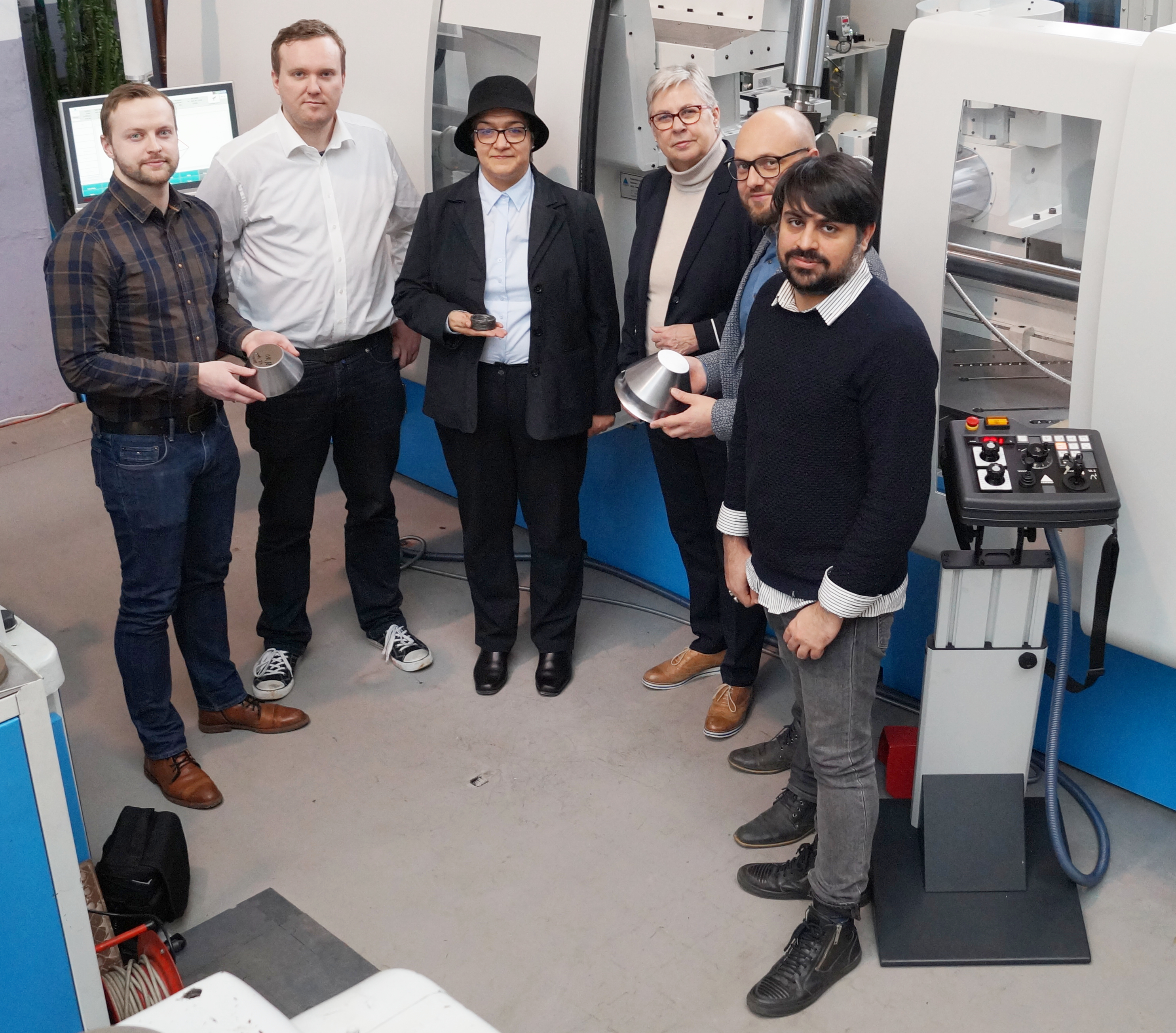

Project team of the TU Chemnitz | Photo: ViF -

Project team in front of the spinning machine | Photo: ViF -

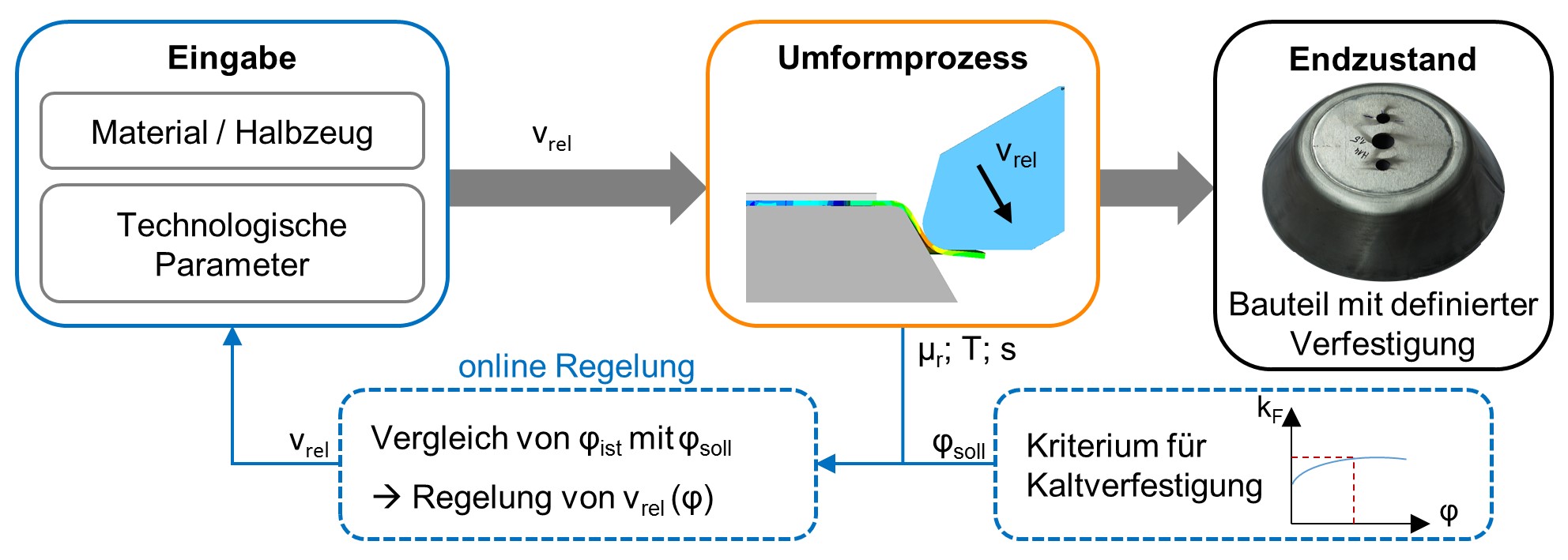

Overview process flow and parameter consideration | Picture: Robert Laue

Start of the SPP 2183: Property-controlled forming processes with Kick-off meeting in Cottbus

On January 14th and 15th, 2020 the Priority Program (SPP) 2183 of the DFG was launched with a Kick-off meeting in Cottbus. The aim of the SPP is to explore the scientific basis of new approaches for process-integrated property control of forming processes. The challenge is to control the process during forming based on the measurement data in order to adjust the desired property in a targeted manner. The new sensors and actuators required for the property control are developed and tested in cooperation between working groups from different disciplines.

The Chemnitz University of Technology is represented by an interdisciplinary research team consisting of the Professorship Virtual Production Engineering (ViF) and the Professorship o of Measurement and Sensor Technology (MST). The aim of the project "Controlled shear spinning for the production of components with defined hardening" (DFG project number: 424334154) is the development of a new control strategy for the incremental forming process. The basic concept consists of the determination and targeted adjustment of the target value strength on rotationally symmetric components during the forming process. For this purpose, a multi-sensor system is used, which consists of a magnetic field sensor with integrated temperature and distance measurement. In addition to the targeted adjustment of component properties, it is also possible to react to external influences such as batch fluctuations or irregularities in the sheet thickness during the forming process.

Dezember 6th, 2019 | Scientists of the Professorship Virtual Production Engineering present current research results in Malaysia and Taiwan

-

Project team at the meeting | Photo: ViF -

Visiting group of Politeknik Sultan Salahuddin Abdul Aziz Shah in Shah Alam | Photo: ViF -

Prof. Awiszus at the inscription in the Golden Book of Politeknik Sultan Salahuddin Abdul Aziz Shah | Photo: ViF -

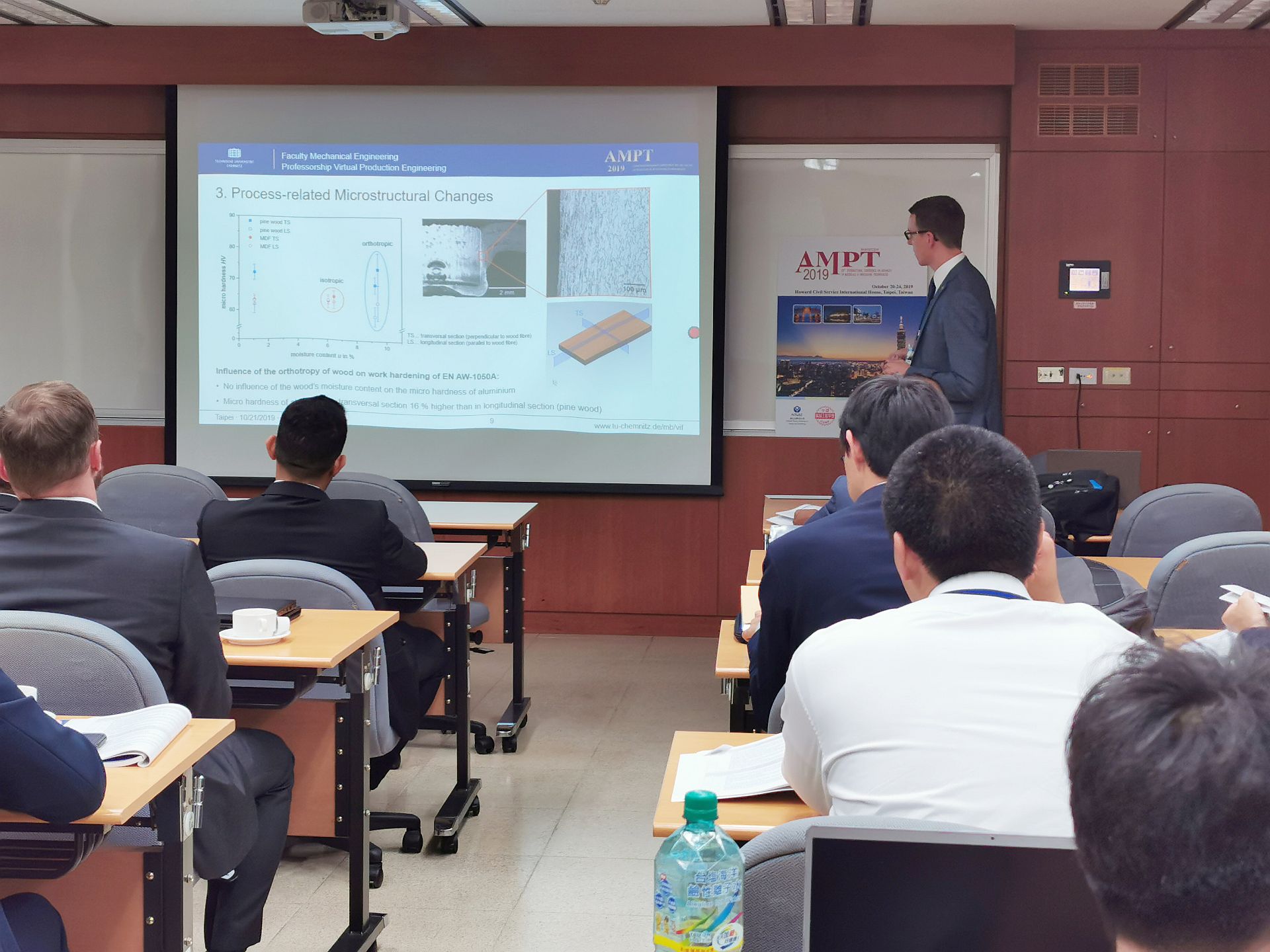

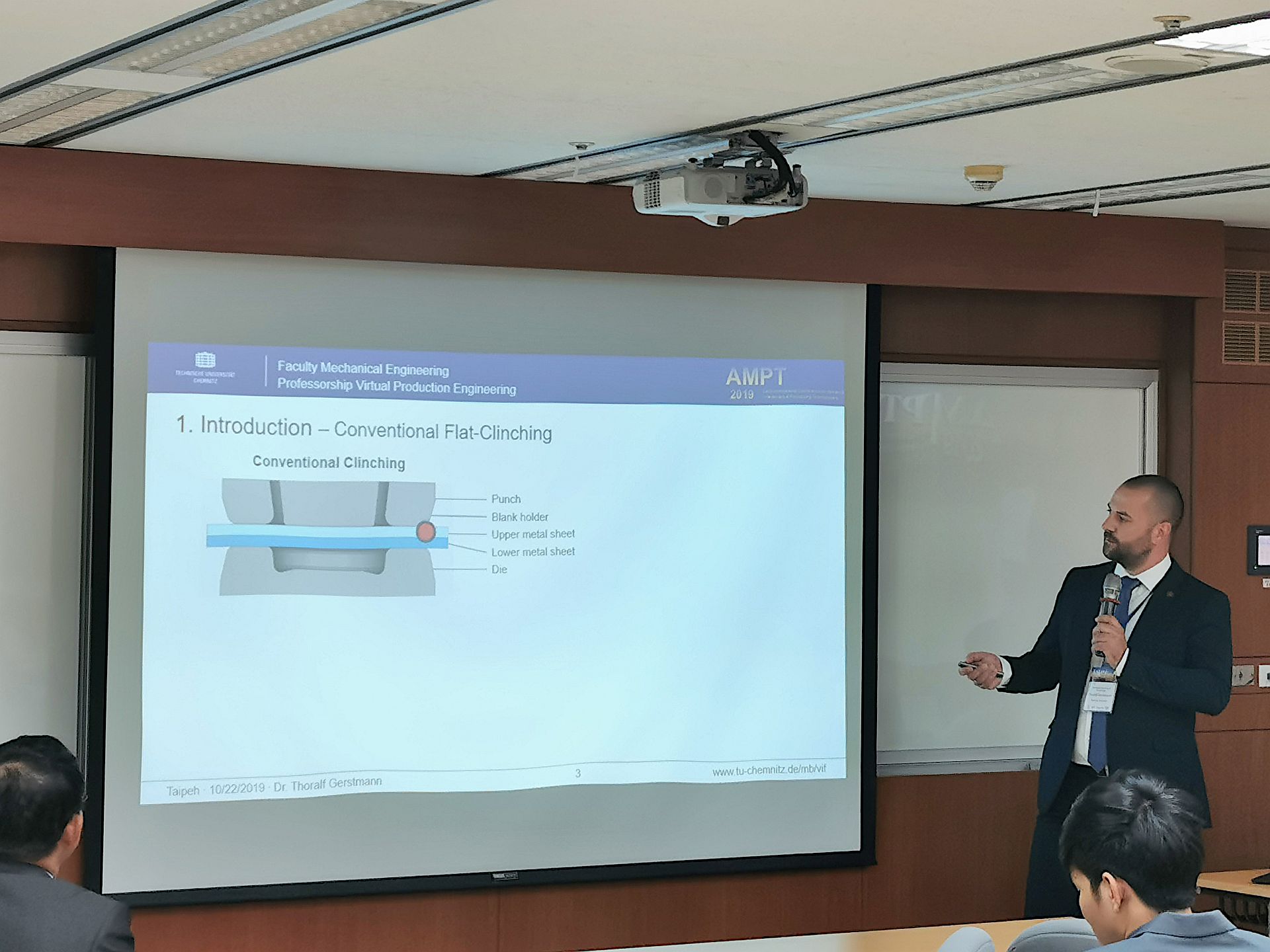

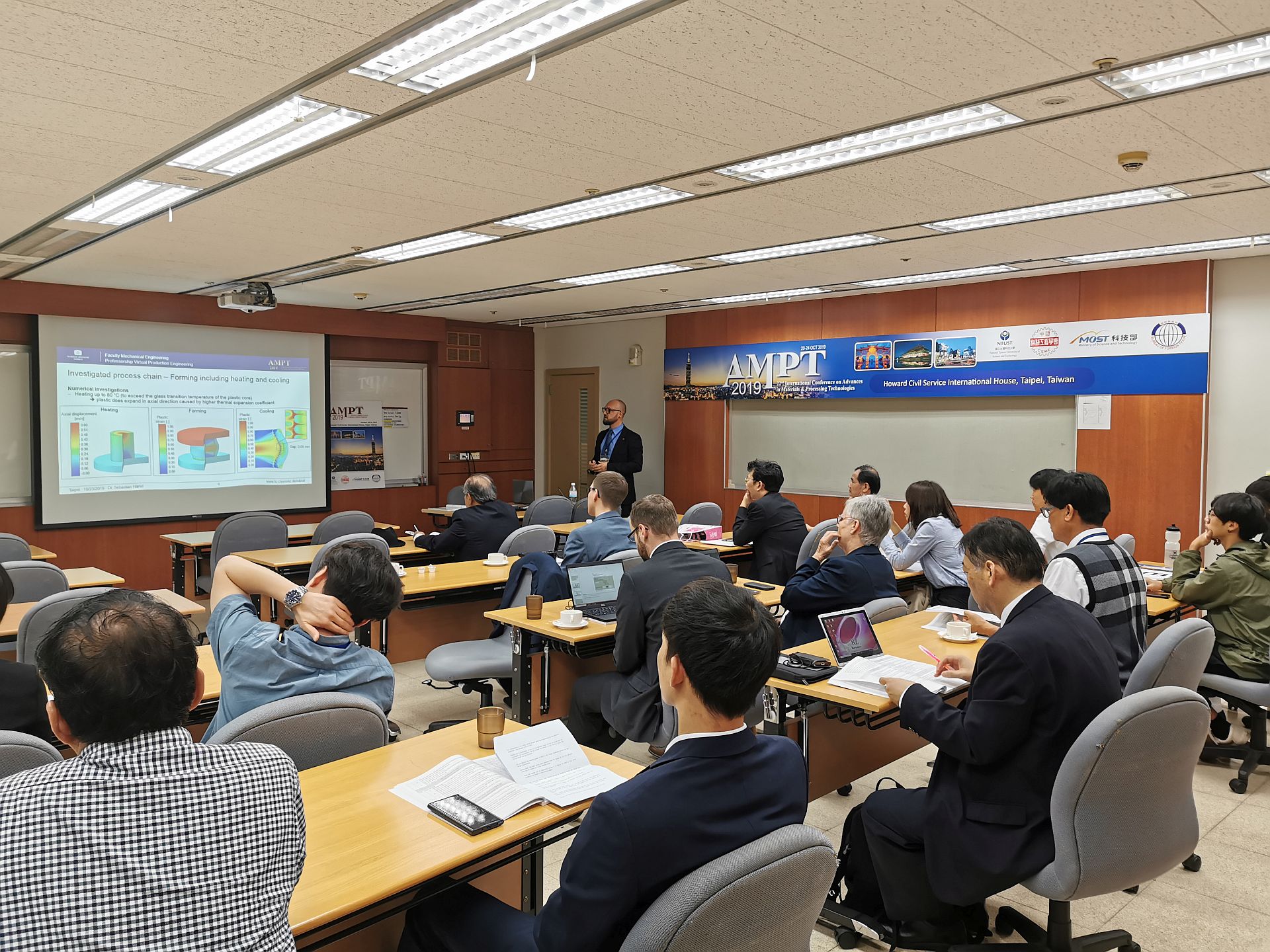

ViF Team at the AMPT | Photo: ViF -

Stephan Lüder giving a presentation at the AMTP | Photo: ViF -

Dr. Thoralf Gerstmann giving a presentation at the AMTP | Photo: ViF -

Robert Laue giving a presentation at the AMTP | Photo: ViF -

Dr. Sebastian Härtel giving a presentation at the AMTP | Photo: ViF -

Giving the award for high quality contributions to Mr. Laue at the conference banquet | Photo: ViF -

Conference participants in front of the National Palace Museum and Yangmingshan National Park | Photo: ViF

Research stay at the UiTM in Shah Alam/Malaysia as part of the DAAD-funded cooperation project

On October 13th 2019 Prof. Awiszus and four research assistants embarked on a one-week research stay at the Universiti Teknologi MARA (UiTM) in Shah Alam/Malaysia. The reason for the stay is a joint research project funded by the German Academic Exchange Service (DAAD). Within the scientific cooperation between the Professorship Virtual Production Engineering (Prof. Awiszus) and the Smart Manufacturing Research Institute (Prof. Yupiter HP Manurung), various case studies on simulation-based method planning for additive-manufactured metal components are currently being developed.

During the first few days, the cooperation partners presented their current state of research to a broad scientific audience. In the subsequent technical discussions, various aspects of the previous work were examined in more detail and future research approaches were derived. In addition to exchanging experiences at UiTM, the German-Malaysian delegation also visited Sultan Salahuddin Abdul Aziz Shah in Shah Alam. After a guided tour of the campus area and a visit to the technical and scientific laboratories, Prof. Awiszus was honoured to sign her name into the institution's Golden Book. In a subsequent talk with the director of the institute, Dr. HJ Mohd Zahari Ismail, and other members of the institute and faculty management, Prof. Awiszus and Dr. Ismail gave an overview of their respective national education and research systems. In this context, the participants discussed advantages and disadvantages of the different systems as well as cooperation possibilities in the fields of research and exchange of scientists and students. After one week, the delegation of the professorship travelled on to Taiwan with many new findings.

Active participation in the international conference in Taipei/Taiwan

The International Conference on Advances in Materials & Processing Technologies (AMPT) took place this year October 20th to 24th in Taipei/Taiwan. For the 22nd time the annual conference discussed topics and trends in manufacturing technology. On this year's main topic: "Smart Manufacturing Technologies in the Age of Industry 4.0" 160 technical papers were presented. Dr. Thoralf Gerstmann and Stephan Lüder were able to leave a lasting impression on the conference participants with their presentations on flat clinching technology. Robert Laue reported on current investigations of radial-rotation profile forming. Finally, Dr. Sebastian Härtel presented the latest findings on the forming of hybrid plastic and metal components. In a second contribution, he described the development of WeldForming, a combination of the welding and forming processes. In addition, Dr. Härtel chaired a session focusing on welding and forming.

The delegation of the TU Chemnitz was honoured for their participation due to the high quality of the contributions. Representing the professorship, Mr. Laue was presented with an award at the concluding conference banquet.

Together with other conference participants the National Palace Museum and the Yangmingshan National Park were visited. The impressive history of the country could be admired and explored. Overall, the conference provided a good framework for scientific and cultural exchange as well as new research impulses.

November 22nd, 2019 | "Working World of Tomorrow - digitization in medium-sized businesses" in Darmstadt

-

Conference documents of the theme day | Photo: ViF -

Opening of the theme day by Dr. Marcus Krastel | Photo: ViF -

Question and answer session after the presentation | Photo: ViF -

Conference participants during the presentation | Photo: ViF -

Interested parties using a HoloLens at the :em engineering methods AG exhibition booth | Photo: ViF

11th of November 2019 the theme day of the Research Association Smart Engineering e.V. took place for the third time in Darmstadt. From 10:00 to 16:00 o'clock Professor Alfred Katzenbach guided the participants as moderator through the event "Working World of Tomorrow - Digitalization in Medium-Sized Businesses". In the presentations by Marc Foullois (Fraunhofer IEM), Jörn Steffen Menzefricke (University of Paderborn), Julian Schallow (IPS Engineers GmbH), Hermann Ferstl and Tanja Sindram (mosaiic GmbH), as well as Professor Torsten Groß (Technical University Mittelhessen), the attendees gained different insights into the implementation of digitalization projects in medium-sized companies. In addition to presenting opportunities and risks as well as possible obstacles, the necessary framework conditions for implementation and numerous practical examples were also presented.

During the lunch break the participants were able the make their first own experiences with the use of a HoloLens and the conversion of requirement analysis in the Augmented Reality at the booth of the :em engineering methods AG.

In the second part of the theme day, the panel discussion once again clearly showed that digitization is changing and influencing daily work processes and private life. In addition to the numerous challenges and problems of digitization, which have already been often discussed, the participants agreed that the consideration of the socio-technical system (humans, technology, organization) is indispensable within the digital transformation. However, only change projects that focus first and foremost on humans and then on technology and processes will be able to achieve sustainable success.

October 22nd, 2019 | New major machine at ViF

-

Delivery of the spinning machines | Photo: ViF -

Spinning machine on crane hook in front of hall E | Photo: ViF -

Spinning machine on crane hook | Photo: ViF -

Spinning machine during placement in the hall E | Photo: ViF -

SC 310 S spinning machine in the production hall | Photo: ViF

Through the "Major Instrumentation" funding program of the German Research Foundation (DFG) and the participation of the Saxon State Ministry for Science and the Arts (SMWK), the Professorship Virtual Production Engineering was able to receive a new high-performance spinning machine with CNC control for current and future research projects in October 2019.

The spinning machine is used for the production of rotationally symmetrical hollow parts from a circular blank by the process principle of spinning. The machine is characterized by a high machine rigidity and high support forces, which enable the forming of steel sheets up to a material thickness of 5 mm.

With this new machine, the expertise in the field of incremental forming processes that has been developed for decades at the Professorship Virtual Production Engineering can be further expanded and researched in a contemporary manner. This is becoming increasingly important as increasing product variants mean that incremental forming is becoming more and more important in industry. Fundamental research into incremental forming processes thus forms an excellent basis for sustainable industrial application. Furthermore, Chemnitz University of Technology is the first Saxon university to integrate this technology in research and teaching.

For further information, please contact, Phone: 0371 531-37384, Mail: sebastian.haertel@mb.tu-chemnitz.de

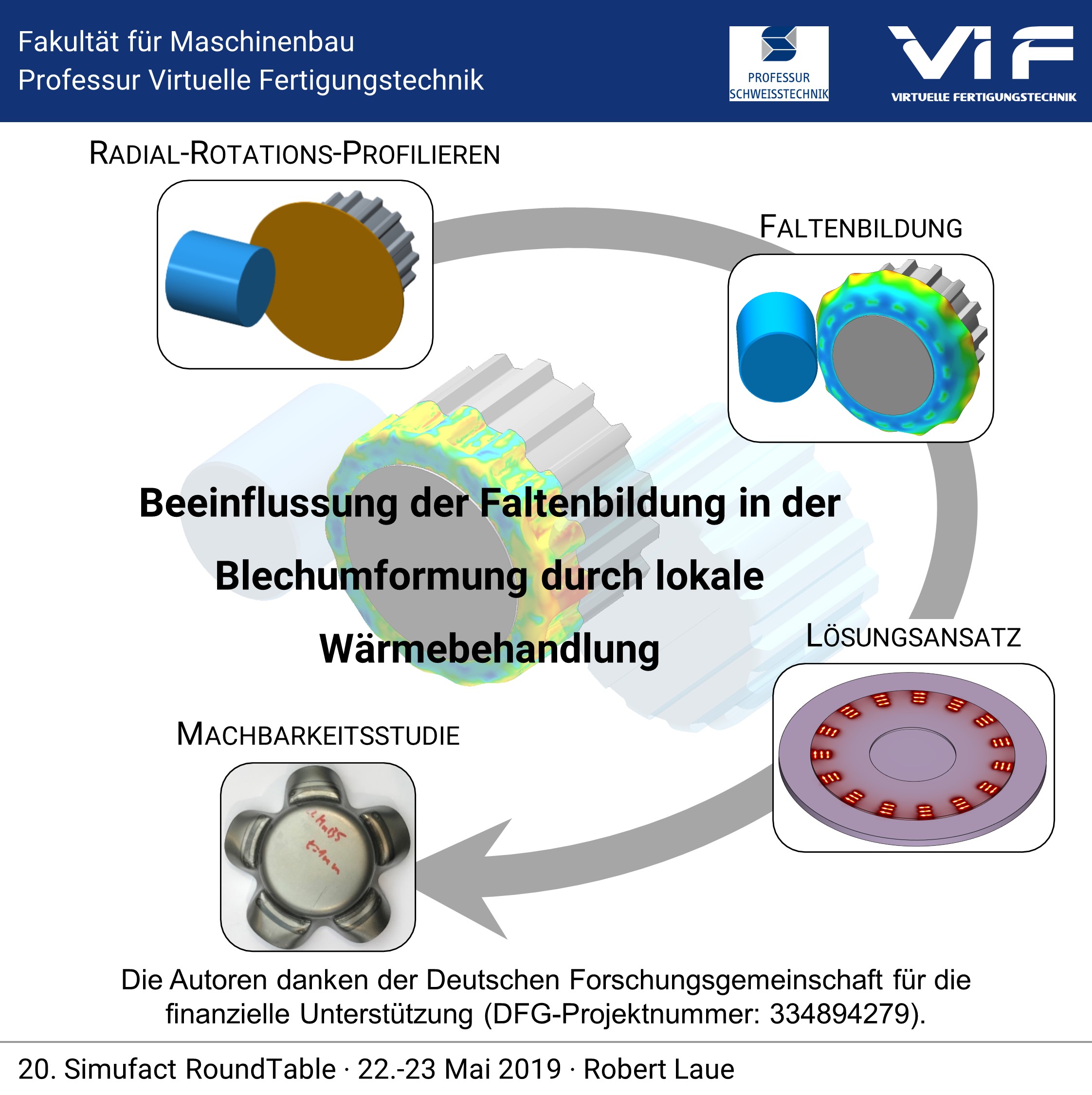

June 6th, 2019 | Simufact RoundTable in Marburg

-

Robert Laue speaking at the Simufact RoundTable | Photo: simufact engineering gmbh -

Overview of the process sequence for radial rotation profil forming | Picture: Robert Laue -

View into the conference room | Photo: simufact engineering gmbh

The Simufact RoundTable is an annual conference for users and experts from industry and science who deal with the simulation of forming, joining and additive manufacturing processes. For the twentieth time, this year the event took place from May 22 to 23 in Marburg.

Robert Laue from the Professorship Virtual Production Engineering presented current research results from the development of the incremental forming process Radial Rotation Profile-Forming. The aim of this process is the production of profiled hollow components with minimal sheet thinning due to the process. For this purpose, a preform with folds is produced. These folds are used specifically for profile forming in the subsequent forming process. Due to the uneven formation of folds, however, identical component properties do not occur globally. As part of his presentation, Mr. Laue presented a research approach on "Influencing wrinkle formation in sheet metal forming by local heat treatment". Based on the numerical analysis of the wrinkle formation, an approach was developed which produces an even wrinkle formation during the preform production. For this purpose, a tailored blank with locally different strengths is produced by an upstream local heat treatment in order to bring about the formation of wrinkles in the areas of lower strength. This approach was validated numerically and experimentally in a feasibility study and forms the basis for further investigations.

Special thanks go to the Chair of Welding Engineering at the Chemnitz University of Technology for their support in laser processing.

April 26th, 2019 | Digitization and Networking in Stuttgart

-

ICS building in Stuttgart | Photo: Jeannette Boll -

Exhibition stand of the FVSE with Jeannette Boll | Photo: Dr. Thoralf Gerstmann -

Conference participants talking during the lunch break | Photo: Ralf Kopp | prostep ivip Verein -

Model of the Mars rover from the prostep ivip association | Photo: Ralf Kopp | prostep ivip Verein

For the 22nd time, the prostep ivip Symposium 2019, one of the largest independent conferences on PLM and digital transformation, took place at the ICS in Stuttgart on April 9th and 10th, 2019. In numerous keynotes, lectures and workshops the participants were able to learn more about the topic "Collaboration in the Age of Smart Products and Services". In addition to the special sessions, the additional exhibition with over 40 booths served visitors to inform themselves casually and network with other experts.

In addition to participating in the symposium, Prof. Birgit Awiszus, Dr. Thoralf Gerstmann and Jeannette Boll presented the research association Smart Engineering e.V. with a booth in the exhibition. In numerous discussions, information about the work of the research association was provided and new interested parties were won for the association.

April 16th, 2019 | Successfull Ph.D. thesis

-

Prof. Awiszus congratulates Michael Hirsch on the successful completion of his PhD | Photo: Dr. Carolin Binotsch -

After a successful defended Ph.D. thesis (from left to right): Prof. Dr. Thomas Bergs (Chair of Manufacturing Technology at WZL/RWTH Aachen), Michael Hirsch (PROFIROLL TECHNOLOGIES GMBH), Prof. Dr. Birgit Awiszus (Professorship Virtual Production Engineering/TUC), Prof. Dr. Sophie Gröger (Professorship Production Metrology/TUC) | Photo: Dr. Carolin Binotsch

Michael Hirsch from PROFIROLL TECHNOLOGIES GMBH successfully defended his Ph.D. thesis on April 2nd, 2019, on the topic "Analysis of the systematic geometric deviation during profile cross rolling of screw profiles". His supervisor Prof. Dr. Birgit Awiszus (Professorship Virtual Manufacturing Technology/TUC) gave advice with technical questions.

The aim of the Ph.D. thesis was to determine and analyze the complex three-dimensional geometric deviation that occurs during profile cross rolling of worm gears and is mainly represented as flank line shape deviation. Furthermore, it was necessary to generate corresponding solutions for compensation. A newly developed mathematical model for predicting the shape deviations now makes it possible to counteract the causes and minimize the deviations.

The examination committee rated the work presented as "magna cum laude" as a very good achievement. We congratulate Dr.-Ing. Michael Hirsch on his successfully completed doctorate.

March 28th, 2019 | SAXSIM 2019

On March 26th 2019 the 11th SAXSIM - Saxon Simulation Meeting took place at the TU Chemnitz. The user meeting offered a network of analytical and CAD-oriented applications, simulations and optimizations. In addition, the participants could inform themselves comprehensively in presentations on current topics of numerical simulation. The employees of the Professorship Virtual Production Engineering also contributed to the conference. Dr.-Ing. Thoralf Gerstmann presented the topic "Hybrid Joining: Numerical Process Development of Flat Clinch Bonding" and Mr. Stephan Lüder presented a contribution to "Methods and Challenges in Numerical Simulation of Selective Laser Melting (SLM)". Dr.-Ing. Marcel Graf and Dr.-Ing. Sebastian Härtel led in several sessions as chairmen through the program.

March 25th, 2019 | MEFORM 2019 in Freiberg

-

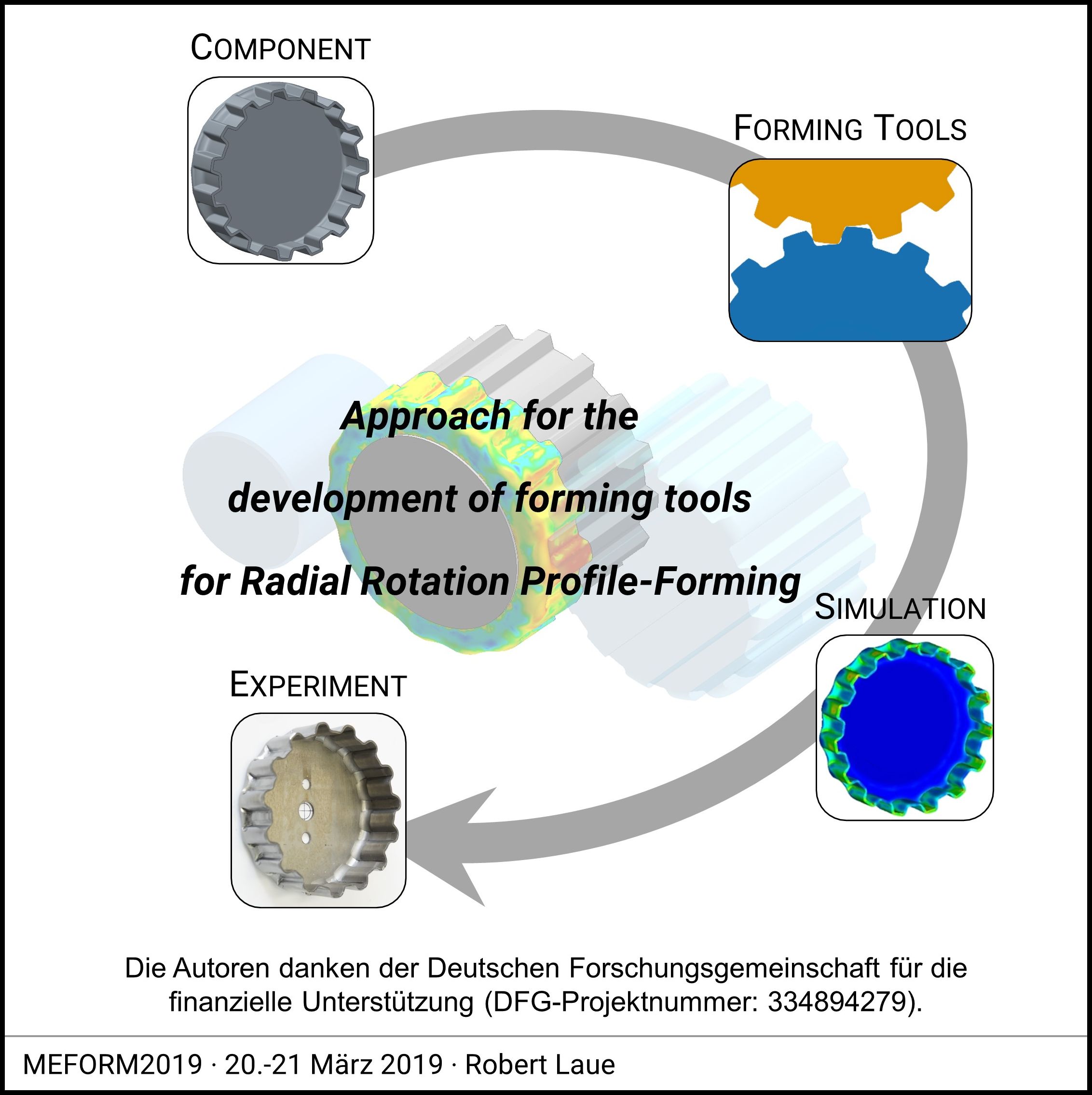

Overview of the development of radial rotation profile forming | Image: Robert Laue -

Conference participants at the lecture | Photo: TU Bergakademie Freiberg

The TU Bergakademie Freiberg hosted the international conference for forming technology (MEFORM) from 19. to 21. of March. More than eighty participants from research and industry, including visitors from eight European countries and Central America, were guests at the annual conference of the Institute of Metal Forming. The focus of the conference was on "Simulation-based technology development for material forming".

Robert Laue from the Professorship Virtual Production Engineering presented current research results on the development of the incremental sheet metal forming process: radial-rotation profile forming. His presentation entitled "Approach for the development of forming tools for Radial Rotation Profile-Forming" focused on the numerically supported development of forming tools and experimental validation. Further information on the lecture can be found in the article of the same name at www.scientific.net/MSF.949.125.

March 18th, 2019 | Best Paper Award at the 21st Materials Technology Colloquium

-

Best Paper Award awarded to Dr. Marcel Graf | Photo: Jörg Riethausen -

Certificate for the 1st prize of the Best Paper Award

At this year's Materials Technology Colloquium, which was hosted by the Institute of Materials Science and Engineering at the TU Chemnitz on March 6th and 07th,2019, our Dr.-Ing. Marcel Graf received the prize for the best conference contribution.

After detailed examination, the jury selected his paper "Study on determination of flow behaviour of 6060-aluminium and AZ31-magnesium thin sheet by means of stacked compression test" with co-authors from the Institute for Metal Forming of the TU Bergakademie Freiberg as "Best Paper". It compared different methods for material characterisation using the example of an aluminium alloy EN AW-6060 and a magnesium alloy TRC-AZ31 in order to generate material data for numerical simulation. Like all contributions to the conference, this article will be published in the conference series "IOP Conference Series: Materials Science and Engineering" (https://iopscience.iop.org/issue/1757-899X/480/1).

Congratulations on the Best Paper Award!

March 12th, 2019 | HZwo at the FC EXPO in Japan

From February 27th to March 1st, 2019 the FC EXPO, the world's largest trade fair for hydrogen and fuel cells, took place at the Tokyo Big Sight in Japan. Mr. Alexander Bauer from the Professorship Virtual Production Engineering also took part in the fair as a project member of the Saxon innovation cluster for fuel cells and hydrogen "HZwo - Antrieb für Sachsen".

Further information: @HZwo_Sachsen

Januar 18th, 2019 | Press release from TUC | Uni Aktuell

-

Personalia

Chemnitzer Professorin ist Mitglied im NFDI-Expertengremium

Chemnitzer Professorin ist Mitglied im NFDI-Expertengremium Prof. Dr. Birgit Awiszus von der Fakultät für Maschinenbau unterstützt mit ihrer Expertise den Aufbau der Nationalen Forschungsdateninfrastruktur (NFDI)

May 7th, 2018 | Long Night of Science | Birth of the TUCelini

-

Waiting participants in hall E of the TU Chemnitz | Foto: W. Förster -

Child operates the deep drawing press | Foto: W. Förster -

Participants observe the forming process on the press | Foto: W. Förster -

the final TUCelini | Foto: W. Förster

As a crowning finale on the "Day of the University", young and old again streamed through the wide-open gates of Hall E at the Reichenhainer Straße campus on Saturday evening. For the third time in a row, interested were able to build their own smoking manikin and learn about various manufacturing techniques. At a total of ten stations, the individual components had to be manufactured and assembled at the end. After the "TUCelino" and the "TUCelina" had already seen the light of day in the last two years, the "TUCelini" was consequently still missing as the child of the two.

The development of the "embryo" began with the receipt of the "birth certificate" at Station 1, which is supervised by the Professorship of Virtual Production Engineering. Here, the body of the TUCelini was manufactured in two stages by deep-drawing a steel sheet. The young researchers were allowed to get hands-on and operate the hydraulic deep drawing press. A simu lation of the deep drawing process provided insights into the process, which is invisible to the eye, and clarified what is meant by "virtual manufacturing". In the further development of the embryo, eyes (drilling), arms (abrasive water jet cutting), hair (welding) and of course the pacifier (turning/milling) were added. After the final assembly and measuring/weighing, the development process was complete and the TUCs were a little family. Since smoking is known to be harmful - especially to children - the TUCelini was given a smoking basket for this purpose.

Meanwhile, the student council of mechanical engineering took care of the physical well-being of the big and small obstetricians and provided outdoor games, if the next "birth pangs" were too long in coming. Generous support for the production of incense was provided by Crottendorfer Räucherkerzen GmbH. The organizers look back on a successful evening that was once again very well received - especially by our young explorers.

21. März 2018 | 20. Werkstofftechnisches Kolloquium - Sonderforschungsbereich 692 erfolgreich abgeschlossen

After 12 years of successful research, the Collaborative Research Center 692 Hals was concluded with a final colloquium on March 14, 2018. The spokesperson of the SFB, Prof. Martin Wagner, once again presented important key points from the three funding periods to representatives of the rectorate as well as numerous participants from the participating institutes and invited guests. In presentations and poster contributions - also from other research groups - essential findings were reported.

By developing, manufacturing and characterizing new lightweight construction concepts, Collaborative Research Center 692 was able to expand the potential of aluminum as the currently most important lightweight construction material. Various approaches were investigated in three research groups.

"High strength wrought aluminum alloys" can be produced by strong grain refinement during high plastic deformation. In this way, the mechanical properties of the materials can be significantly improved. Investigations using a special forming process (ECAP - Equal Channel Angular Pressing) provided directional insights into the microstructural relationships of the strength increase. In addition, semi-finished products were also produced on an industrially relevant scale.

"Aluminum matrix composites" were also investigated, as they show considerable potential in applications under elevated temperatures or tribological stress. High-energy milling was used to generate composite powders and subsequently produce compact semi-finished products. Additional forming by ECAP resulted in a more homogeneous distribution of the reinforcing particles and also improved the mechanical properties.

The Professorship Virtual Production Engineering was involved in the third group "Al-Mg Composites" with subproject B3. In this project, the forming production of aluminum-magnesium composites was investigated. Due to their magnesium content, these composites are characterized by a weight saving of up to 21% compared with solid aluminum. Since magnesium is highly susceptible to corrosion, the aluminum cladding provides effective protection. Hydrostatic extrusion was investigated as the manufacturing process, with which composite strands with a diameter of 20 mm and a length of about 3.5 m could be extruded. These in turn served as the starting semifinished product for further investigations into the formability of such composites by die forging. This showed that more complex geometries can also be produced. A challenge was presented by the end faces of the semi-finished products, where the magnesium was still in contact with the ambient atmosphere after forming and was therefore susceptible to corrosion. By machining the semi-finished products, it was possible to completely enclose the magnesium core during subsequent forming. During the process, all manufacturing steps were numerically mapped using the finite element method and provided important insights that contributed significantly to the understanding of the process. In the 12 years of intensive research and scientific exchange, it was thus possible to create a process chain for the forming production and further processing of aluminum-magnesium composite components.

February 27th 2017 | Information day "Smart Engineering" - A successful event with lively discussions

-

photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Opening of the information day "Smart Engineering" by Prof. Dr. Birgit Awiszus (Professorship Virtual Production Engineering Chemnitz University of Technology and board of the research association Smart Engineering e.V.) | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Prof. Dr. Birgit Awiszus and Rachel Bauer (ProSTEP iViP) | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Dr. Christian Tschirner (head of the department of Fraunhofer Institute for Mechatronic Systems Design (IEM)) | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Dr. Christian Tschirner (head of the department of Fraunhofer Institute for Mechatronic Systems Design (IEM)) | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Andreas Faath (employee of TU Darmstadt in the Department of Computer Integrated Design, representative on behalf of Prof. Dr. Reiner Anderl) | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Andreas Faath (employee of TU Darmstadt in the Department of Computer Integrated Design, representative on behalf of Prof. Dr. Reiner Anderl) | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Prof. Dr. Rainer Stark (manager of the business segment Virtual Product Creation of Fraunhofer Institute for Production Systems and Design Technology (IPK)) | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Prof. Dr. Rainer Stark (manager of the business segment Virtual Product Creation of Fraunhofer Institute for Production Systems and Design Technology (IPK)) | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Dr. Marcus Krastel (:em engineering methods AG and board of the research association Smart Engineering e.V.) | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Dr. Marcus Krastel (:em engineering methods AG and board of the research association Smart Engineering e.V.) | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Lively discussions at the World Café | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Lively discussions at the World Café | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Lively discussions at the World Café | photo: research association "Forschungsvereinigung Smart Engineering e.V." -

Prof. Dr. Thomas Mechlinski (Laboratory for Product Data Management at the Osnabrück University of Applied Sciences and board of the research association Smart Engineering e.V.) | photo: research association "Forschungsvereinigung Smart Engineering e.V."" -

Prof. Dr. Thomas Mechlinski (Laboratory for Product Data Management at the Osnabrück University of Applied Sciences and board of the research association Smart Engineering e.V.) | photo: research association "Forschungsvereinigung Smart Engineering e.V."

The first information day "Smart Engineering" took place in Darmstadt on February 14th, 2017 and was a complete success. 36 participants accepted the invitation of the research association "Forschungsvereinigung Smart Engineering e.V." and participated in the event. Among the participants were experts and scientists of several colleges, universities and research institutes as well as of IT companies and users from the industry within the field of PDM/PLM, virtual product development and digitalization. Purpose of the information day was to inform about latest problems of the topics smart engineering, industry 4.0 and engineering in the product life cycle as well as to provide a forum for discussions and communication.

Prof. Dr. Birgit Awiszus (Professorship Virtual Production Engineering Chemnitz University of Technology and board of the research association Smart Engineering e.V.) initiated the information day and guided the participants through the event. The keynote speakers were Dr. Christian Tschirner, head of the department of Fraunhofer Institute for Mechatronic Systems Design, Andreas Faath, employee of TU Darmstadt in the Department of Computer Integrated Design, and Prof. Dr. Rainer Stark, manager of the business segment Virtual Product Creation of Fraunhofer Institute for Production Systems and Design Technology.

Afterwards, Dr. Marcus Krastel (:em engineering methods AG and board of the research association Smart Engineering e.V.) reported explicitly about the research association "Forschungsvereinigung Smart Engineering e.V.". He presented the latest activities, the achievements so far, the close collaboration with the ProSTEP iViP association as well as the various possibilities to become active as a member of the research association.

The further development of research fields was another issue discussed as part of the following World Café. Thereby, the expectations of the participants towards the research association, current research activities and the further need for research within the field of smart engineering was discussed intensively.

Finally, Prof. Dr. Thomas Mechlinski (Laboratory for Product Data Management at the Osnabrück University of Applied Sciences and board of the research association Smart Engineering e.V.) spoke about future activities of the research association and presented in cooperation with Dr. Krastel and Prof. Awiszus a first résumé of the World Café.

Due to the consistently positive feedback of the participants, the research association plans a regular repetition of similar events. The "Forschungsvereinigung Smart Engineering e.V." gives special thanks to all participants for the lively discussions and to the ProSTEP iViP association for the consultative support. Both factors contributed to the success of the information day.

The research association "Forschungsvereinigung Smart Engineering e.V." remains open for interested members. We are looking forward to your participation!

More information: www.fv-smartengineering.org

February 7th 2017 | Press Release of the IUNO (National Reference Project on IT Security in Industry 4.0)

Prof. Dr. Birgit Awiszus elected to the advisory board of the IUNO consortium

On February 2nd 2017 the newly formed advisory board met for the first constituent meeting

Read moreSeptember 20th 2016 | Successfull Ph.D. thesis

-

After a successful defended Ph.D. thesis (from left to right): Prof. Dr. Birgit Awiszus (TUC); Prof. Dr. Bernd-Arno Behrens (Leibniz Universität Hannover); Dr.-Ing. Thoralf Gerstmann und Prof. Dr. Sophie Gröger (TUC). -

The auditorium at the PhD lecture.

On August 18th 2016 Mr. Thoralf Gerstmann defended with distinction his Ph.D. thesis on the topic of "Enhancement of the process limitations of flat-clinching". Within the context of the thesis he developed new process variations by the help of numerical and experimental investigations. The variations are called "flat-clinching with a complementary joining element" and "adhesive flat-clinching".

Flat-clinching with a complementary joining element increases the joint strength significantly by inserting a complementary joining element into the joint. This causes an enlargement of the interlocking, leading to a higher resistance to cross tension loads. Moreover the joint is stabilized by the additional material and the resistance to shear load is improved. The second process variation, adhesive flat-clinching, includes the combination of flat-clinching and adhesive bonding. The metal sheets are fixed by flat-clinching and the final joint strength is achieved after the complete curing of the adhesive. This enables a continuous processing of the component and therefore, the process time can be shortened.

The presented Ph.D. thesis was valued as outstanding work by the board of examiners and achieved the grade "summa cum laude". We congratulate Dr.-Ing. Thoralf Gerstmann on his outstanding thesis.

June 3rd 2016 | Successfull Ph.D. thesis

-

Prof. Awiszus congratulates Lena Maaß on her successful PhD thesis -

After a successful defended Ph.D. thesis (from left to right): Prof. Dr. Birgit Awiszus (TUC), Lena Maaß, Prof. Dr. Martin Rambke (Hochschule Ostfalia), Prof. Dr. Bernd Platzer (TUC) and Dr.-Ing. Dipl.-Kffr. Susanne Bolick (TUC)

On May 20th 2016 Mrs. Lena Maaß successfully defended her Ph.D. thesis on the topic of "Strategic integration of forming simulations into the development process chain of car bodies". Her thesis considered the integration of forming simulations into the process chain of car body development. Moreover a data transfer between the simulation programs of the process chain "forming - joining - crash" was realised.

As part of the thesis a method for designing an addendum was developed. This proved that the simulation results of the inverse simulation, relating to sheet metal thickness and plastic strain, can be significantly approximated to the results of the incremental reference simulation by the help of an addendum. The developed method makes a high contribution towards the increase of quality of the subsequent process simulations within the process chain.

We congratulate Mrs. Dr. Maaß on her successful PhD!

April 15th 2016 | Interdisciplinary networking of female scientists within the field of MINT | Blog entry MERGE

From March 14th to 15th 2016 the third Interdisciplinary Symposium for female Engineers and Natural Scientists (ISINA) took place at the Technische Universität Chemnitz. The symposium served as a platform for nearly 70 participants for interdisciplinary knowledge transfer and exchange of different topics within the field of MINT.

On two days, experts from science and economy gave talks on latest topics within their field of science and research. In this context Jeannette Boll, Anja Rautenstrauch and Christina Symmank presented their main research results on the topic "Multi-criteria evaluation of process chains for the resource-efficient manufacturing of hybrid structures". Apart from the presentation of the evaluation method MEMPHIS, which is a basis for analyzing and evaluating production process chains in the field of hybrid structures with regard to energy efficiency, cost-effectiveness and robustness, a brief excursus on the positive and fascinating aspects of working as a scientist in the technical field was given to the audience.Furthermore, with a short speech Anja Bochmann gave insights into the different fields of research within the Cluster of Excellence MERGE.

June 16th 2015 | Press release from TUC | Uni Aktuell

-

Ehrungen

Auszeichnung für wissenschaftliche Veröffentlichung mit hoher Praxisrelevanz für die industrielle Anwendung

Auszeichnung für wissenschaftliche Veröffentlichung mit hoher Praxisrelevanz für die industrielle Anwendung Professuren Konstruktionslehre und Virtuelle Fertigungstechnik der TU Chemnitz erhalten „Simufact Scientific Publication Award 2015“

31. März 2015 | 2nd place at "Jugend forscht"

On November 6, 2015 Henriette Kunze a student of "Karl-Schmidt-Rottluff" school in Chemnitz was honored within the contest "Jugend forscht" which is organized by the Chamber of Industry and Commerce Chemnitz annually. With her assignment about the application of computer-aided design and simulation methods she won the second place.

Within the field of mechanical and production engineering, a lot of new techniques and methods established in the last decades which were not imaginable before. In her assignment Mrs. Kunze investigates the newest developments by comparing historical design technology to computer-aided techniques which are nowadays used in the field of mechanical engineering. On the basis of her own construction example she was able to demonstrate the huge variety of possible applications for virtual technologies.

Henriette Kunze started her investigation on modern computer-aided design methods in summer 2009 (student of 9th grade) during an internship at the Department of Virtual Product Engineering. In the context of this internship she acquired the basic knowledge for operating with CAD systems which she reinforced by studying on her own after the internship. As a result of her constant self-studying she succeeded in modelling parts and assemblies in three-dimensional space.

During the work on her assignment Mrs. Kunze was supported by Dr. Elke Bombach and Dr. Andreas Feuerhack - both employees at the Department of Virtual Product Engineering.

December 2nd 2014 | Press release from TUC | Uni Aktuell

-

Ehrungen

Ausgezeichnete Forschungsarbeit

Ausgezeichnete ForschungsarbeitMaschinenbauer der TU Chemnitz erhielten für ihre Forschung zur Kombination von Reib- und Formschluss den Best Paper Award der International Conference on Technology of Plasticity

May 23rd 2014 | Excellent Ph.D.

-

Prof. Awiszus congratulates Andreas Feuerhack on the successful completion of his PhD -

After a successful defended Ph.D. thesis (from left to right): Prof. Dr.-Ing. Erhard Leidich (TUC), Prof. Dr.-Ing. A. Erman Tekkaya (TU Dortmund), Dr.-Ing. Andreas Feuerhack und Prof. Dr.-Ing. Birgit Awiszus (TUC)

Andreas Feuerhack defended his Ph.D. thesis with the title "Experimental and numerical analysis of Al-Mg compounds by compound forging" successfully on May 23rd 2014.

Content of the work was the formability of hybrid Al-Mg compounds. Based on experimental analyses of the fundamental forming processes (upsetting, spreading and uprising) a load direction dependency of the formability of hybrid Al-Mg compounds was proofed. To visualize critical areas of the interface damage in the numerical simulation a macro-mechanical damage model was developed. In a very good presentation, the audience was able to learn more about possible optimization strategies, such as the modification of the sleeve-core ratio and the specific application of eccentricity in addition to the substantive content of the thesis.

We congratulate Dr.-Ing. Andreas Feuerhack to his successful PhD and we wish him the best for the future!

April 29th 2014 | Euro Hybrid Materials and Structures 2014 | Blog entry MERGE

MERGE researchers and scientists from TU Chemnitz attended the "Euro Hybrid Materials and Structures 2014" from April 10 to 11, 2014 in Stade. The lectures focused on basics of hybrid materials and structures, characterization, material behavior during processing, design of hybrid structures and recycling as well as repair and maintenance. Participants of the Cluster of Excellence MERGE presented latest research results from IRD A1 (Sebastian Arnold), IRD A3 (Claudia Friederichs), IRD B2 (André Albert), IRD B4 (Jeannette Katzenberger) and IRD E1 (Alexandra Yulinova). The scientists led discussions about high-performance hybrid laminates and special applications in Lightweight Structures to establish new contacts and form interdisciplinary and cross-sectoral networks. For more information about the conference please visit the website: http://www.dgm.de/dgm/hybrid/

April 7th 2014 | Press release from TUC | Uni Aktuell

-

Forschung

Es gibt viele Wege, Technologien und Arbeitsabläufe zu verbessern

Es gibt viele Wege, Technologien und Arbeitsabläufe zu verbessernHannover Messe: Wissenschaftler der TU Chemnitz präsentieren vom 7. bis 11. April 2014 aktuelle Forschungsergebnisse auf dem mitteldeutschen Gemeinschaftsstand "Forschung für die Zukunft"

April 3rd 2014 | Press release from TUC | Uni Aktuell

-

Ehrungen

Schülerinnen auf dem Weg in die Wissenschaft

Schülerinnen auf dem Weg in die WissenschaftTU Chemnitz zeichnete am 3. April 2014 erstmalig drei talentierte Nachwuchsforscherinnen für ihre hervorragenden "Besondere Lernleistungen" in den MINT-Fächern mit dem "BeLL-PRIX" aus

January 29th 2014 | Successfull Ph.D. thesis

-

Prof. Awiszus congratulates Stefan Kleditzsch on his successful Ph.D. -

After a successful defended Ph.D. thesis (from left to right): Prof. Dr. Michael Gehde (TUC), Dr.-Ing. Stefan Kleditzsch , Prof. Dr. Birgit Awiszus (TUC) und Prof. Dr. Peter Groche (TU-Darmstadt) -

Stefan Kleditzsch during his PhD lecture

The quickly and accurately analysis of flow forming processes as well as its evaluation was the aim of the Ph.D. thesis by Stefan Kleditzsch "Beitrag zur Modellierung und Simulation von Zylinderdrückwalzprozessen mit elementaren Methoden". The incremental forming process flow forming is characterized by a complex kinematics, small contact areas and from numerical point of view with a large computation time. By applying methodical and systematic analysis of the process specifics of flow forming the analytical tools FloSim and ModIni were improved by implementing an advanced geometry model as well as a new temperature model. The very good presentation of the extensive results gave the audience an insight of flow forming and the complex mathematical approaches to describe the forming process.

We congratulate Dr.-Ing. Stefan Kleditzsch to its successful PhD and we wish him and his short while ago extended family the best for the future!

January 29th 2014 | Press release from TUC | Uni Aktuell

Der Bogen vom Maschinenbau in die IT-Technik

Prof. Dr. Birgit Awiszus übernimmt den Vorsitz der Kommission für IT-Infrastruktur der Deutschen Forschungsgemeinschaft

January 14th 2014 | Successfully completed Ph.D. thesis

-

Prof. Awiszus congratulates Sebastian Pinner on his successful PhD -

After a successful defended Ph.D. thesis (from left to right):: Prof. Dr. Peter Mayr (TUC), Dr.-Ing. Sebastian Pinner, Prof. Dr. Birgit Awiszus (TUC) und Prof. Dr. Martin Rambke (Hochschule Ostfalia) -

Dr.-Ing. Sebastian Pinner with individually designed doctoral hat and Prof. Awiszus

On January 14th 2014 Mr. Sebastian Pinner, employee of Volkswagen AG, defended his Ph.D. with the title "Untersuchung von Methoden zur durchgängigen Prozesskettensimulation im Karosseriebau" successfully. The work was part of the research project VIPROF, which was funded by the BMBF within the framework concept "Research for Tomorrow's Production", and deals with the continuous simulation of the manufacturing processes forming, joining, painting and crash. Based on the studies on the influence of the production history on the product features and on connecting FEM systems with each other and with a PDM system, a guideline for the use of this process chain simulation concept in the automotive industry had been developed.

We congratulate Dr. Pinner most sincerely on his successful accomplishment!

June 6th 2013 | Press release from newspaper | Freie Presse

April 8th 2013 | Press release from TUC | Uni Aktuell

Maschinenbauprofessorin auf den Spuren zukünftiger IT-Trends

Prof. Dr. Birgit Awiszus reiste mit einer Study-Tour der Deutschen Forschungsgemeinschaft zu hochkarätigen Forschungsinstituten der Informationstechnologie in den USA

March 25th 2013 | Successful presentation at the INTEC

-

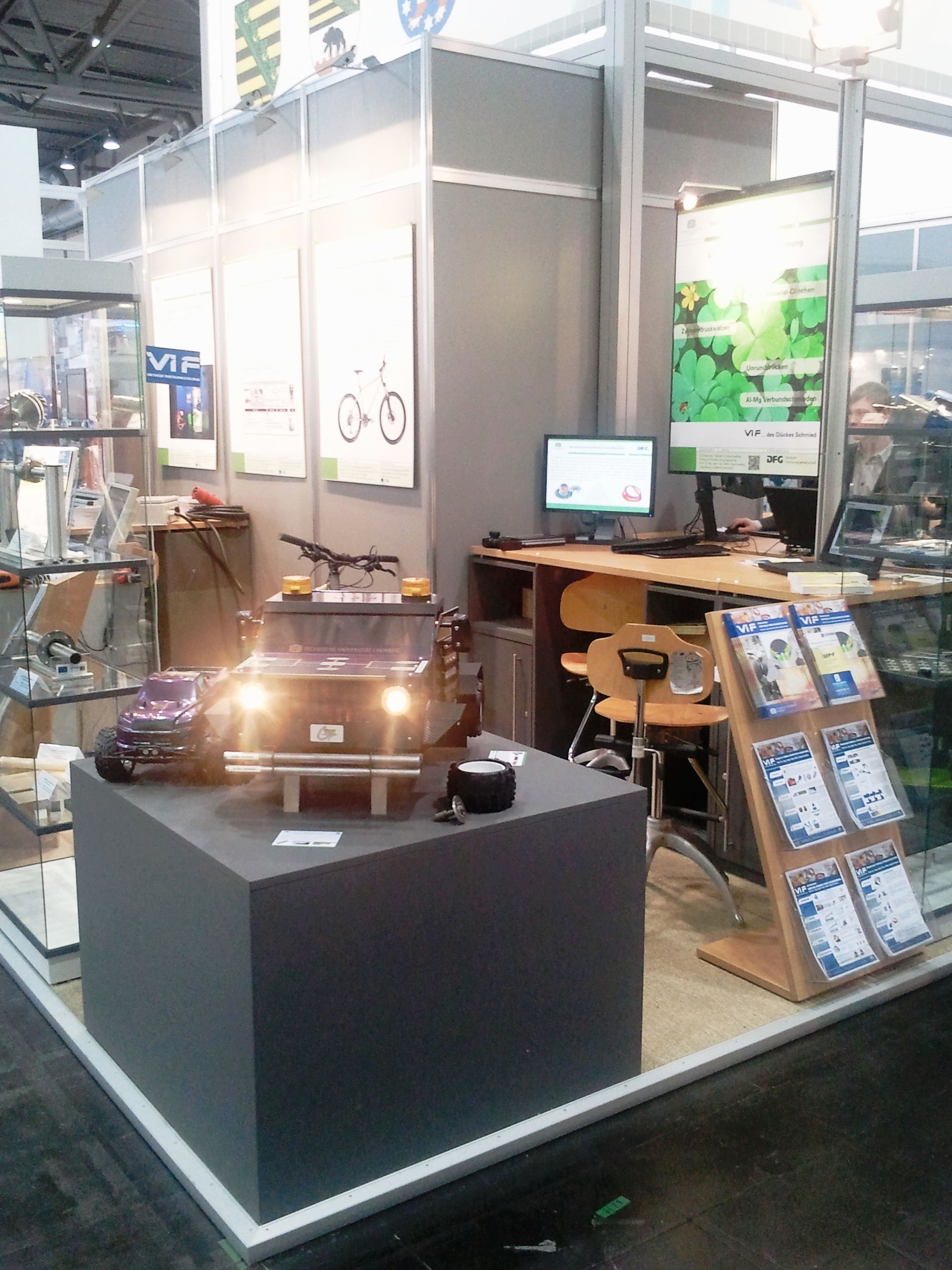

The "ViF-Mobil" at INTEC -

Matthias Schuffenhauer at the exhibition booth -

Exhibition booth of the professorship ViF -

Stefan Kleditzsch at the exhibition booth

The Chair of Virtual Production Engineering presented its research activities from February 26st to March 1st 2013, represented by Andreas Feuerhack, Thoralf Gerstmann, Stefan Kleditzsch and Matthias Schuffenhauer, at the INTEC in Leipzig. The visitors could discover the research results in the field of numerical simulation and forming through the so-called "ViF-Automobile" at the exhibition stand "Forschung für die Zukunft".

February 22nd 2013 | Press release from TUC | Uni Aktuell

Anfassen erwünscht: Das Auto für Entdecker

Professur Virtuelle Fertigungstechnik vereint vom 26. Februar bis 1. März 2013 auf der INTEC in Leipzig viele Forschungsergebnisse in einem einzigartigen Modellauto

February 7th 2013 | Excellent "non-circular" Ph.D.

-

Prof. Awiszus congratulates Sebastian Härtel on the successful completion of his PhD -

After a successful defended Ph.D. thesis (from left to right): Prof. Dr. Bernd-Arno Behrens, Dr.-Ing. Sebastian Härtel, Prof. Dr. Birgit Awiszus und Prof. Dr. Egon Müller

On February 7th 2013 Mr. Sebastian Härtel defended his Ph.D. thesis with the title "Experimental and numerical investigations for developing non-circular spinning" successfully. In his presentation, Mr. Härtel did not only show his specialized knowledge but also gave a better understanding of the topic even to the non-specialist audience by using visual and tangible illustrative material.

The examination committee chaired by Prof. Dr.-Ing. Egon Müller evaluated the presented work as an excellent achievement with the grade "summa cum laude". We congratulate Dr. Härtel to this successful accomplishment!

January 9th 2013 | A "pattern based" Ph.D.

-

After a successful defended Ph.D. thesis (from left to right): Prof. Dr. Michael Gehde (chairman, TUC), Prof. Dr. Birgit Awiszus (reviewer, TUC), Dr.-Ing. Dominik Rohrmus und Prof. Dr. Nassir Navab (reviewer, TU München) -

Dr.-Ing. Dominik Rohrmus with his PhD hat

On January 9th 2013 Mr. Dominik Rohrmus, employee of Siemens AG, defended his Ph.D. thesis with the title "Adaptive invariant features for texture classification". The thesis dealt with the development of a method for the extraction and classification of position-invariant texture features from digital greyscale camera images. This method is used for a flexible (in terms of product variants), reproducible and rapid texture analysis for the automatic inspection of the surface quality of industrially manufactured products.

We congratulate Dr. Rohrmus most sincerely to this successful accomplishment!!

November 6th 2012 | Press release from TUC | Uni Aktuell

Exzellenzcluster "MERGE" offiziell gestartet

Wissenschaftler aus sechs Fakultäten der TU Chemnitz forschen in den kommenden fünf Jahren, um getrennte Fertigungsprozesse bei der Verarbeitung unterschiedlicher Werkstoffgruppen zusammenzuführen

October 24th 2012 | New Multimedia Educational System for computer lab B501

Coinciding with the beginning of the winter semester 2012/13, the multimedia educational system with digital screen transmission "alphadidact DVI" was put into operation in the computer lab B501 of the Chair of Virtual Production Engineering. Using the new system, computer-aided courses (e.g. "Product Data Technology" or "Simulation in Forming Technology") can be designed more vividly. It gives the tutor the possibility to transmit additional information to the students workstations while giving a presentation. Furthermore, in case of problems, students can be attended individually or in groups. The educational system, funded by the Department of Mechanical Engineering, improves the quality of the offered courses significantly.

September 18th 2012 | Press release from TUC | Uni Aktuell

Als Team ausschlaggebend für den Erfolg

Am 17. September 2012 trafen sich die beteiligten Wissenschaftler des Bundesexzellenzclusters MERGE zur Informationsveranstaltung - offizielle Auftaktveranstaltung am 16. November

June 25th 2012 | ViF also performing excellent research

After many months of waiting, on June 15th 2012 it was announced which projects will be funded in the second phase of the Excellence Initiative by the German Federal and State Governments. After a stressful application process the Technical University of Chemnitz reached the final round with the Clusters of Excellence "MERGE - Fusion technology for multi-functional lightweight structures". Thus, the joy was enormous, when the approval of the application of the Clusters of Excellence was announced in a press conference by the DFG (German Research Foundation) at 15:30 p.m.

The Chair of Virtual Production Engineering (ViF) is involved in one sub-project of this Clusters of Excellence and is responsible for the "Networking Area" of MERGE. ViF is very pleased about this extraordinary success, and the related further strengthening of Chemnitz as a science and research location.

Further information: (available in German only)

"Exzellenz und Relevanz sind unser Markenzeichen"

TU Chemnitz wird im Rahmen der Exzellenzinitiative von 2012 bis 2017 mehrfach gefördert - Wichtige Zukunftsthemen im Leichtbau und in der Halbleitertechnologie können nun in Angriff genommen werden

June 13th 2012 | Press release from TUC | Uni Aktuell

Gutachter und Strategen der Forschung

Drei Professoren der TU Chemnitz arbeiten derzeit ehrenamtlich in einem der 48 Fachkollegien der Deutschen Forschungsgemeinschaft

May 21st 2012 | Press release from newspaper | Freie Presse

May 11th 2012 | Successful Ph.D.

On May 11th 2012 Mr. Kai Kittner defended his Ph.D. thesis with the title "An integrative model approach for co-extrusion of aluminum-magnesium compounds" successfully. In a very entertaining presentation Mr. Kittner captivated the audience by using visual and tangible illustrative material to give a better understanding of the topic of hydrostatic co-extrusion of aluminum-magnesium compounds.

The examination committee evaluated the presented work as an especially commendable achievement with the grade "magna cum laude". We congratulate Dr. Kittner! Congratulations to the successful accomplishment!

April 2012 | Honor for commendable transfer of technology

This year's Scientific Award goes to the Chair of Virtual Production Engineering from Chemnitz University of Technology. During the 13th International RoundTable "Simulation in Metal Forming Technology", Prof. Dr. Birgit Awiszus received the honor which is initiated by the Simufact GmbH and given for outstanding collaboration and commendable transfer of technology.

"I am especially pleased that this year's award goes to Chemnitz. The prize reflects the excellent collaboration in the field of joint research projects as well as the close cooperation between software-vendor and end user", says Dr. Ralph Bernhardt, Head of Research and Development at Simufact GmbH.

Detailed press release from TUC (May 9th 2012)

January 23rd 2012 | Outstanding PhD with honors

On January 23rd 2012 Ms. Ulrike Beyer defended her doctoral thesis on "Multi-material joining using flat-clinch technology" successfully. The Examination Committee, chaired by Prof. Dr.-Ing. Michael Gehde, evaluated the presented work unanimously with the grade "summa cum laude". Congratulations to Dr. Beyer on this outstanding achievement!

June 15th 2011 | Flat-Clinch Technology integrated on new Eckold Press

On June 15th, the new Eckold Press (DFG 500/150E) was put in operation solemnly at the Department of Virtual Production Engineering. In addition to Prof. Awiszus (head of department), the employees involved in the project (Ms. Beyer, Mr. Schuffenhauer and Mr. Heuer) and the representatives of Eckold GmbH & Co. KG (Managing Director Dr. Beyer, Mr. Skolaude and Mr. Unger) were present. As part of the commissioning the Flat-Clinch Technology was shown, which is now used industrially for the first time. At this point we would like to say thank you again to the Eckold GmbH & Co. KG for its generous support.

On June 15th, the new Eckold Press (DFG 500/150E) was put in operation solemnly at the Department of Virtual Production Engineering. In addition to Prof. Awiszus (head of department), the employees involved in the project (Ms. Beyer, Mr. Schuffenhauer and Mr. Heuer) and the representatives of Eckold GmbH & Co. KG (Managing Director Dr. Beyer, Mr. Skolaude and Mr. Unger) were present. As part of the commissioning the Flat-Clinch Technology was shown, which is now used industrially for the first time. At this point we would like to say thank you again to the Eckold GmbH & Co. KG for its generous support.

December 1st 2010 | Press release from TUC | Uni Aktuell

Anerkennung für eine "runde" Diplomarbeit

Thoralf Gerstmann, junger Wissenschaftler der Professur Virtuelle Fertigungstechnik, belegt den ersten Platz beim "Sächsischen Preis für Umformtechnik 2010"

October 21st and 22nd 2010 | ENGINSOFT International Conference 2010 in Montichiari, Italy

The annual conference ENGINSOFT International 2010 was held this year in Montichiari, Italy. The conference theme was CAE-technology for the industry. In addition the ANSYS and FORGE user meetings were held. A total of 600 participants were able to learn in 90 lectures and 30 posters about current research findings and new applications in the field of CAE-technology. The Department of Virtual Production Engineering presented recent simulation results of the KRM planetary cross-rolling process at the FORGE user meeting.

The annual conference ENGINSOFT International 2010 was held this year in Montichiari, Italy. The conference theme was CAE-technology for the industry. In addition the ANSYS and FORGE user meetings were held. A total of 600 participants were able to learn in 90 lectures and 30 posters about current research findings and new applications in the field of CAE-technology. The Department of Virtual Production Engineering presented recent simulation results of the KRM planetary cross-rolling process at the FORGE user meeting.

October 2010 | New tension compression testing machine

The ViF team led by Prof. Awiszus obtained an intensive overview of the latest developments in the joining technology and numerical simulation. Furthermore, there was the opportunity for many conversations at the joint stand of the European Research Association for Sheet Metal Processing with colleagues from other universities and research institutions. At this point we would like to thank the EFB and the Company Eckold GmbH & Co. KG for their generous support again, without such a successful participation in this exhibition would not have been possible. One more note: The next big trade fair event: The Hannover Messe 2011. Here, the Department of Virtual Production Engineering will have its own stand for the first time, where the latest research results of various projects will be presented.

The ViF team led by Prof. Awiszus obtained an intensive overview of the latest developments in the joining technology and numerical simulation. Furthermore, there was the opportunity for many conversations at the joint stand of the European Research Association for Sheet Metal Processing with colleagues from other universities and research institutions. At this point we would like to thank the EFB and the Company Eckold GmbH & Co. KG for their generous support again, without such a successful participation in this exhibition would not have been possible. One more note: The next big trade fair event: The Hannover Messe 2011. Here, the Department of Virtual Production Engineering will have its own stand for the first time, where the latest research results of various projects will be presented.

October 2010 | ViF-delegation traveling to the EuroBlech 2010

The world's largest trade fair for sheet metal forming took place from October 26th to October 30th 2010 at the exhibition grounds in Hannover. Under the overall theme "Time for innovation" 1455 exhibitors from 43 countries showed the latest trends in metal processing manufacturing.

The world's largest trade fair for sheet metal forming took place from October 26th to October 30th 2010 at the exhibition grounds in Hannover. Under the overall theme "Time for innovation" 1455 exhibitors from 43 countries showed the latest trends in metal processing manufacturing.The ViF team led by Prof. Awiszus obtained an intensive overview of the latest developments in the joining technology and numerical simulation. Furthermore, there was the opportunity for many conversations at the joint stand of the European Research Association for Sheet Metal Processing with colleagues from other universities and research institutions. At this point we would like to thank the EFB and the Company Eckold GmbH & Co. KG for their generous support again, without such a successful participation in this exhibition would not have been possible. One more note: The next big trade fair event: The Hannover Messe 2011. Here, the Department of Virtual Production Engineering will have its own stand for the first time, where the latest research results of various projects will be presented.

September 2010 | 12th International Round Table 2010 - Simulation in Bulk Metal Forming

From September 27th to September 30th 2010 the annual Simufact RoundTable took place in Bamberg. Due to the international orientation of the 12th RoundTable more than 160 national and international participants had the opportunity to talk about the process of simulation, its applications and their experience in the different fields. In addition there was the possibility to make transnational contacts. As a part of the conference Ms. Dipl.-Ing. Dipl.-Wirtsch.-Ing. Ulrike Beyer, Dipl.-Ing. Kai Kittner and Dipl.-Ing. Thoralf Gerstmann from the Department of Virtual Production Engineering presented the latest research findings on the topics of the hybrid Flat-Clinch connection, the flow behavior of aluminum-magnesium composite materials and the development of hybrid meshes to a broad audience.

From September 27th to September 30th 2010 the annual Simufact RoundTable took place in Bamberg. Due to the international orientation of the 12th RoundTable more than 160 national and international participants had the opportunity to talk about the process of simulation, its applications and their experience in the different fields. In addition there was the possibility to make transnational contacts. As a part of the conference Ms. Dipl.-Ing. Dipl.-Wirtsch.-Ing. Ulrike Beyer, Dipl.-Ing. Kai Kittner and Dipl.-Ing. Thoralf Gerstmann from the Department of Virtual Production Engineering presented the latest research findings on the topics of the hybrid Flat-Clinch connection, the flow behavior of aluminum-magnesium composite materials and the development of hybrid meshes to a broad audience.

September 19th - 22nd 2010 | Metal Forming 2010 in Toyohashi, Japan

For the first time, the biennial Metal Forming took place outside of Europe. This year 2010 it was carried out in Japan. The 13th conference covered a wide range of topics with a number of 366 publications from 27 countries. The Department of Virtual Production Engineering participated with four presentations in the areas of bulk metal forming, sheet metal forming, mechanical joining and composite extrusion. All of them received an excellent response to the presented research results.

For the first time, the biennial Metal Forming took place outside of Europe. This year 2010 it was carried out in Japan. The 13th conference covered a wide range of topics with a number of 366 publications from 27 countries. The Department of Virtual Production Engineering participated with four presentations in the areas of bulk metal forming, sheet metal forming, mechanical joining and composite extrusion. All of them received an excellent response to the presented research results.

September 1st 2010 | 5th "Firmenlauf Chemnitz"

Every year all over again: The fifth company run took place September 1st 2010 in Chemnitz. In total, about 2100 runners from 262 companies rose to the challenge to run the 4.8 km long route through central Chemnitz. Among these runners were also four employees of the Department of Virtual Production Engineering. Despite their great love of sports, the amateurs in running Thoralf Gerstmann, Andrea Junghanns, Jeannette Katzenberger and Kai Kittner could not occupy one of the top places. Yet they were rewarded with the title "sportiest company" which the Chemnitz University of Technology won, as in the previous two years. This was due to the 122 starters of the TUC. Thank you to all the runners and we are looking forward to the next run!

Every year all over again: The fifth company run took place September 1st 2010 in Chemnitz. In total, about 2100 runners from 262 companies rose to the challenge to run the 4.8 km long route through central Chemnitz. Among these runners were also four employees of the Department of Virtual Production Engineering. Despite their great love of sports, the amateurs in running Thoralf Gerstmann, Andrea Junghanns, Jeannette Katzenberger and Kai Kittner could not occupy one of the top places. Yet they were rewarded with the title "sportiest company" which the Chemnitz University of Technology won, as in the previous two years. This was due to the 122 starters of the TUC. Thank you to all the runners and we are looking forward to the next run!

07. und 08. Juni 2010 | FORGE USER MEETING 2010 in Sophia Antipolis, France

The French software company Transvalor, software developer in the field of numerical simulation for forging, invited to the 8th User Conference in Sophia Antipolis. At the annual user meeting Transvalor presented the latest developments and trends in software for FORGE 2011. In addition to the presentations by Transvalor many other users showed their work, rounding off the program. Also the Department of Virtual Production Engineering presented its current simulation results of the KRM planetary cross-rolling process.

The French software company Transvalor, software developer in the field of numerical simulation for forging, invited to the 8th User Conference in Sophia Antipolis. At the annual user meeting Transvalor presented the latest developments and trends in software for FORGE 2011. In addition to the presentations by Transvalor many other users showed their work, rounding off the program. Also the Department of Virtual Production Engineering presented its current simulation results of the KRM planetary cross-rolling process.

17. Juni 2010 | 17th Innovation Day - for small and medium-sized businesses in Berlin

On the outdoor multi-technology showcase more than 200 companies and research institutions throughout Germany presented their new products, processes and services that have been developed with financial support of the innovation funding of the Federal Ministry of Economics and Technology (BMWi).