Department of Sustainable Materials and Processing

Welcome to the Sustainable Materials and Processing department.

Our department conducts research and development into new materials and their processing methods. The background to this is the approach that modern, application-adapted materials in combination with newly conceived processing routes have the potential to make our society's technologies sustainable. In our research and development work, we always follow the so-called R-strategies. For example, we are reducing the amount of materials required and the process energy needed, designing products in such a way that they can be recycled or reprocessed, or investigating possibilities for the simple and material-adapted extraction of secondary materials. The current research projects focus on steels, aluminium materials and metal matrix composites. In addition to analytical, characterising and testing methods, material and process simulation tools are also used to ensure comprehensive adaptation - i.e. an adaptation that takes into account material characteristics on different size scales and under different application and processing conditions.

Under the tabs displayed at the top edge of this screen area, you will find more detailed information on our research achievements, the services we offer and the extensive equipment and methodological facilities of our department.

Do you have any further questions or can we support you in your tasks? Then simply contact us at the telephone number or e-mail address below.

We look forward to working with you!

The team in the Sustainable Materials and Processing department is currently conducting research into high-strength aluminium materials and steels as well as aluminium and nickel composites.

Our work with aluminium and composite materials focuses on investigating their processing using additive manufacturing processes and the necessary upstream treatment and processing steps as well as their resulting application properties. In the case of aluminium composites, we also look at their processability using kneading processes and the possibilities for their recycling.

Our work with steels deals with heat treatment effects in sheet materials, the simulative design of thermal and thermomechanical treatment processes and their influence on the steel microstructure and properties.

Below you will find a selection of our most important research topics in the above-mentioned areas.

We will be happy to advise or support you with our expertise in solving your tasks.

Just get in touch with us!

- Calculation of local material properties during thermal and thermomechanical treatment of steels

- Modelling of heat treatment processes and simulation of locally generated microstructures and heat treatment states

- Optimisation of heat treatment processes to specified material target properties with the aid of neural networks

- Design of melt and powder metallurgical process routes for the production of particle-reinforced AMC with high reinforcement phase content with special consideration of internal phase interfaces.

- Development of analysis and testing methods for the reproducible recording of microstructural properties and material characteristics of particle-reinforced AMC with high reinforcement phase content

- Improvement of the tribological properties of particle-reinforced light and heavy metal composites with a high proportion of reinforcing phases with the aim of achieving practical freedom from wear

- Design of material pairings in tribological systems, especially in systems with (partial) solid contact

The range of services offered by the Materials Development and Analysis department includes analytical and investigative tasks as well as simulation-supported, targeted materials development.

The technical equipment available to us for this purpose can be found sorted by laboratory area under the corresponding tab on this page.

We offer the following services as standard.

Contact us if you would like us to support you in special tasks!

- X-ray fine structure analysis using XRD:

-

- Qualitative and quantitative phase analysis and determination of the lattice parameters

- Determination of particle sizes and micro distortions

- Residual stress measurement

- Texture analysis

- Coating thickness, roughness and density determination by means of reflectometry

- Simultaneous performance of thermogravimetry (TG) and optionally differential thermal analysis (DTA) or dynamic differential calorimetry (DSC)

- Thermomechanical analysis (TMA) to determine the behaviour of materials under mechanical and thermal loading

- Mechanical testing of materials, especially metal matrix composites (tensile test, bending test and ILS test)

- Various standardised wear tests in solid contact

- Fatigue testing in the LCF and HCF range under tensile, compressive and bending loads

- Heat treatments according to specifications and development of heat treatment routines

- FEM simulations (e.g. forming simulations, heat treatments…)

- Calculation of material data and material parameters (especially of steels)

- High Energy Ball Mill Zoz Simoloyer CM08-8l

- High energy ball mill Zoz Simoloyer CM01-2l / SiN

- Planetary ball mill Fritsch Pulverisette 5

- Powder atomisation system

- AMC casting device

- Electric arc furnace (use via Professorship PVW)

- Spark plasma sintering system (SPS) (use via Professorship PVW)

- Materialographic preparation technique

- Electron microscopic preparation technique

- Light microscopic examination technique

- Quantitative microstructure analysis OLYMPUS a4i

- Micro hardness tester DURAMIN

- Recording hardness measurement FISCHERSCOPE HM2000 XYm

- Scanning electron microscope LEO1455VP with X-ray micro-range analysis EDAX GENESIS

- Field emission scanning electron microscope NEON40EsB with EDXS and EBSD

- Transmission electron microscope HITACHI H8100 with X-ray microrange analysis EDAX GENESIS

- Nanoindenter UNAT

- Resonance pulsator RUMUL - Wöhler tests

- Resonance pulsator RUMUL - crack propagation tests

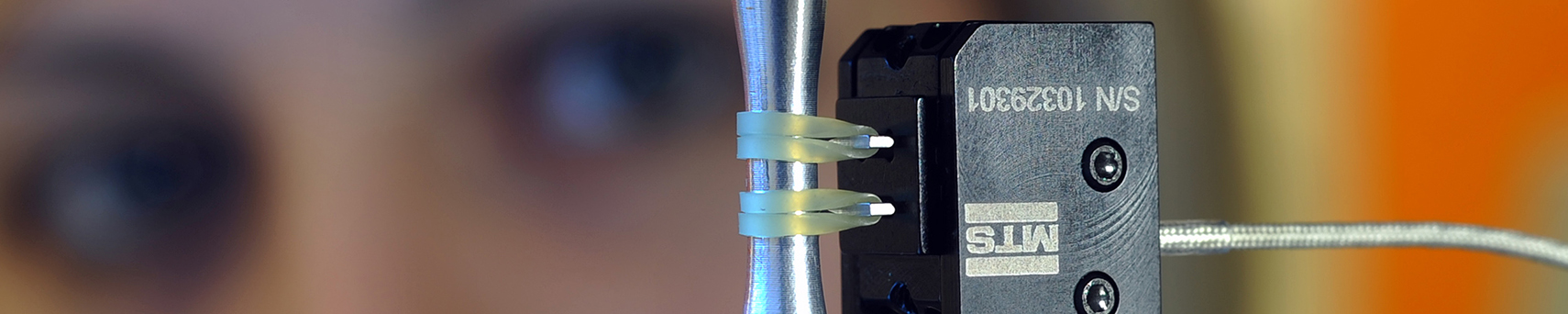

- MTS Landmark (100kN) equipment - strain-controlled fatigue tests

- MatLab

- Mathcad

- Deform

- Fluent

- JMatPro

- ABAQUS

- ANSYS

- MemBrain

- Model tests in the laboratory

- Boil test (intergranular and stress corrosion cracking test)

- Corrosion test chamber HK 400

- Potentiostat PS6 (determination of current density potential curves)

- Electrochemical MiniCell (ECMC)

- Pitting and crevice corrosion test, ASTM G48

- Climate test chamber

- Microcorrosion cell

- Corrosion test chamber HK 430

- 3-D profilometer

- pH-value measuring device

- X-ray fluorescence material analyser

- Colour and Gloss Meter BYK Gardener spectro-guide

Contact