News

Sustainable Products

Up to now, technical products have often been assessed for their full sustainability spectrum only after they have been developed. In the case of revolutionary products and disruptive developments, there is no generational development, so there is no information on the sustainability of previous generations. In the absence of information on previous generations, the assessment can only be a rough guide due to a lack of information, and will become more precise as more information on the product becomes available during product development. In this way it is possible to assess the sustainability of any product, regardless of its history. In addition, the knowledge gained from the previous product can be used through appropriate documentation.

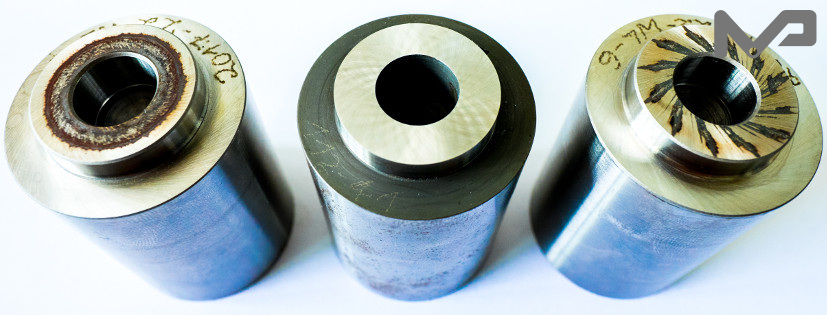

IKAT welcomes new staff member for the shaft-hub-connections/fatigue division

IKAT welcomes Dipl.-Ing. Maik Zylla as a new member of staff. Following his apprenticeship as an industrial mechanic and further education as a state-certified technician for mechatronics, he completed his degree in mechanical engineering at our university at the beginning of this year. During his studies, Mr Zylla specialised in design engineering and product development, worked for three years as a student trainee in the development department at thyssenkrupp Dynamic Components GmbH and wrote his thesis on the topic of „external knurling press fit“. In addition to his technical expertise, he is interested in cycling, hiking, fitness training and 3D printing. Welcome to the team, Mr Zylla!

PhD defense in the topic of feather key connections

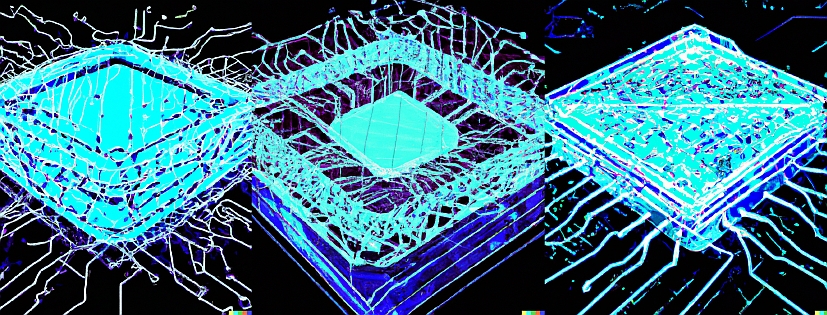

Topology optimization of a compliant mechanism

Here you can see the topology optimisation of a shape-adaptive compliant mechanism. Compliant mechanisms are characterised by the fact that they generate desired deformations through elastic distortions.

The starting point for the design is a design space filled with finite elements.

A topology optimisation approach developed at IKAT scales the stiffness of the finite elements in such a way that a structure is created which, due to its stiffness properties, can generate the desired deformation under essentially any load. We refer to such compliant mechanisms as compliant mechanisms with selective compliance.

The desired deformation was defined here as the free surface deforming in the form of a sinusoidal curve under arbitrary forces. The optimisation algorithm designs the structure in such a way that it can fulfil this function well.

We show that a sinusoidal deformation can actually be achieved regardless of the force applied by loading the structure with arbitrary forces.