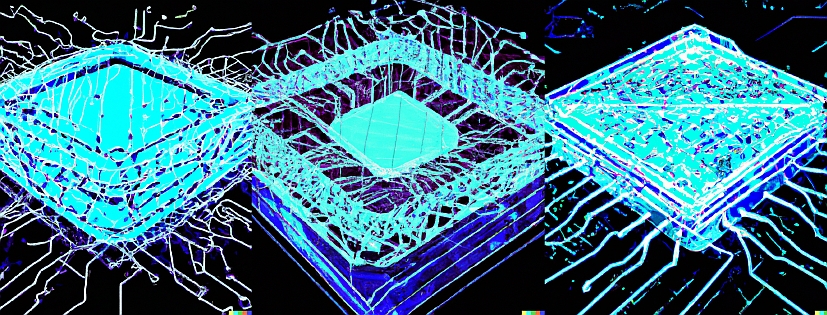

AI in design

Artificial Intelligence in Design

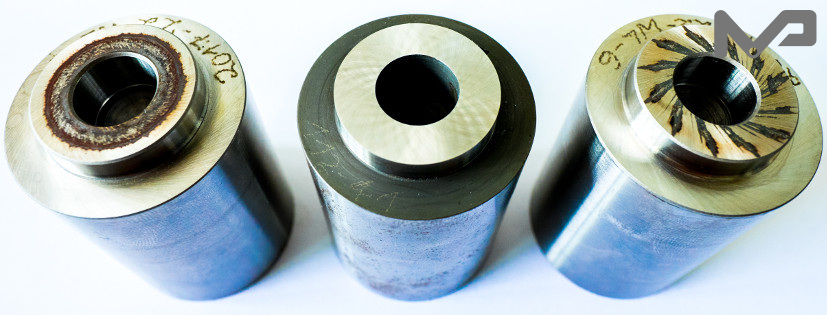

Shaft-Hub Connections

Strength tests in time, fatigue and fatigue strength on selected positive and non-positive joints

Friction Corrosion

Interdisciplinary Research between Tribology and Strength Strength Assessment of Joints at Risk of Friction Fatigue Fracture

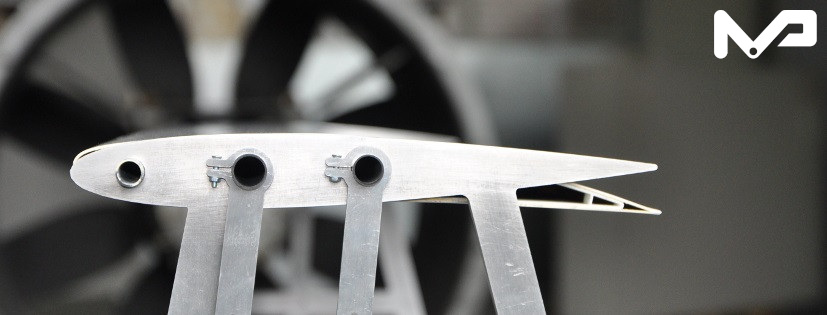

Compliant Mechanisms

Synthesis and analysis methods for Compliant Mechanisms

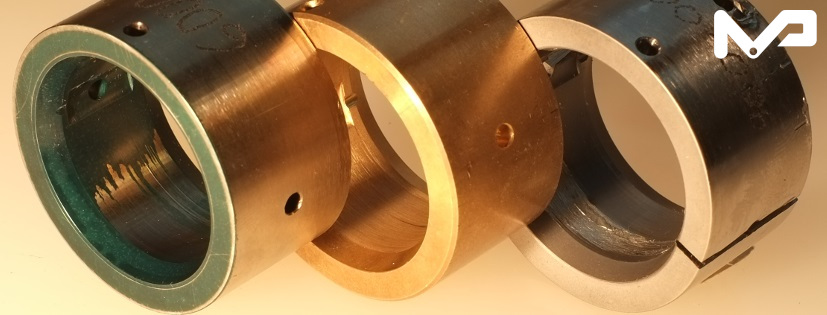

Hydrodynamic/Plain Bearings

Investigation in all areas - solid, mixed and fluid friction: simulation, toleration, production and coating

Strength of Gearing

Experimental, numerical and analytical strength tests of gear teeth

Friction coefficients for force-locked Connections

Investigations of the static/dynamic friction coefficient behaviour with standardized model test methods on laboratory samples

Sustainable Products

nterdisciplinary research for the development of sustainable products and transition engineering

The professorship Machine Elements and Product Development pursues not only the research of machine elements in their overall interactions but also the goal of synthesizing flexible systems. Above

all, tribological, stress mechanical, geometric, systemic and economic effects are focused. Here, established simulation and calculation methods and a wide range of spectrum of tests can be used.

Research

Growing ecological and economic pressure leads to ever higher and more complex stresses in the development of plain bearings. The research at the institute is therefore primarily concerned with the investigation and development of alternative sliding materials and the influence of geometric deviations. The main focus of the investigations is the wear behavior under the most varied operating conditions (particles, mixed friction, hydrodynamics).

The permissible loads of selected WNV (tapered and cylindrical interference fit as well as feather key, knurled, polygonal joints, etc.) have been investigated primarily at IKAT for decades in the area of fatigue, fatigue and fatigue strength. The behavior under individual loads (bending, torsion) as well as combined dynamic loads is analysed.

In contact with various components, deformations in connection with the prevailing joint pressure initiate the damage process of fretting fatigue. Current research activities at the institute focus on basic research on the damage phenomenon of fretting fatigue and pursue the objective of developing an impact-compliant calculation method.

While conventional mechanisms owe their deformability to the sliding or rolling interfaces in the joints, flexible mechanisms fulfill their function through elastic stretches in places that are deliberately designed to be flexible during design. This functional principle enables novel, shape-adaptive structures, which can be used, for example, in softrobotics or in variable-shape wings. The professorship focuses its research on optimization-based synthesis methods.

The strength tests focus on the tooth root load-bearing capacity of worm gear units. The challenge to numerical imaging lies in the complex geometry and the special material bronze.

The coefficient of static friction (also: coefficient of friction or coefficient of friction) is to be understood as a system variable with a multitude of influencing parameters. In order to use existing potentials in friction-locking connections (e.g. screw, flange, press-fit connections), an experimental investigation is indispensable. With the help of standardized test methods on model samples, a wide variety of tribological configurations are examined at the research centre with regard to their transmission behavior. A major field of research is the synthesis of new design/selection tools for friction-enhancing measures (e.g. micro/laser structures, hard particles, coatings) for static and dynamic load cases.