Friction Coefficient Determination and Synthesis for Friction-Locked Joints

Investigations of static/dynamic friction-coefficient behavior using standardized model test methods on laboratory specimens

1 General description

Growing economic and ecological pressure as well as increased technical requirements lead to higher power densities in force-transmitting/friction-locked components. The frequently used frictional joints (e.g., bolted, flanged, and interference fits) offer considerable potential for increasing power density and wear resistance. Using model-based laboratory tests, IKAT has been researching the static friction coefficient (also: coefficient of friction) under static and dynamic loading for over 10 years. The main research areas include the characterization of friction-locked surfaces, friction-enhancing applications, and remedial measures against vibrational wear (fretting wear).

2 Research focus

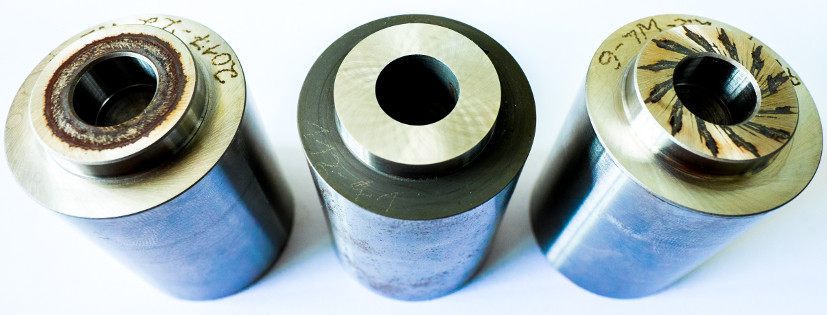

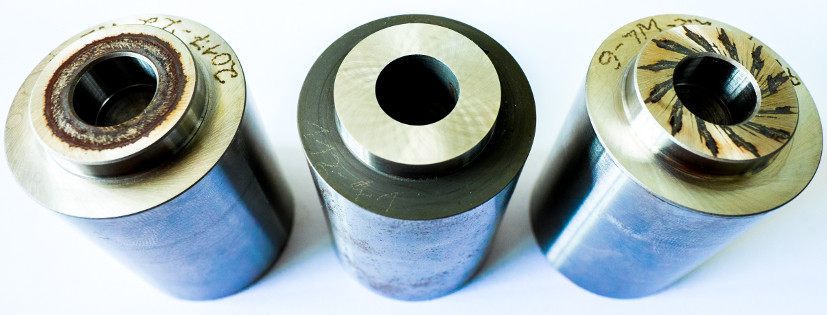

The static friction coefficient (also: coefficient of friction) is to be understood as a system quantity with a multitude of influencing parameters. To exploit existing potential in friction-locked joints, experimental investigation is indispensable. Using standardized test methods on model specimens, a wide variety of tribological configurations are examined at the research facility with regard to their transmission behavior. A main research field is the synthesis of new design/selection tools for friction-enhancing measures (e.g., micro/laser structures, hard particles, coatings) for static and dynamic load cases. Furthermore, remedial measures against fretting wear can be examined and evaluated for their suitability using these test methods.

3 Tools

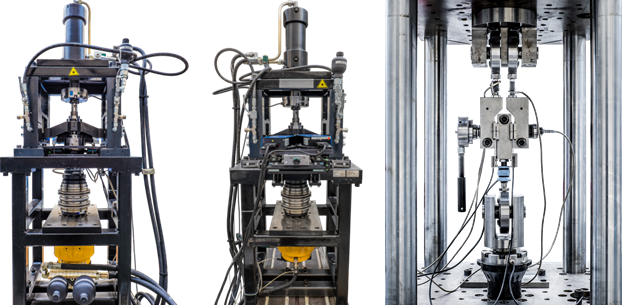

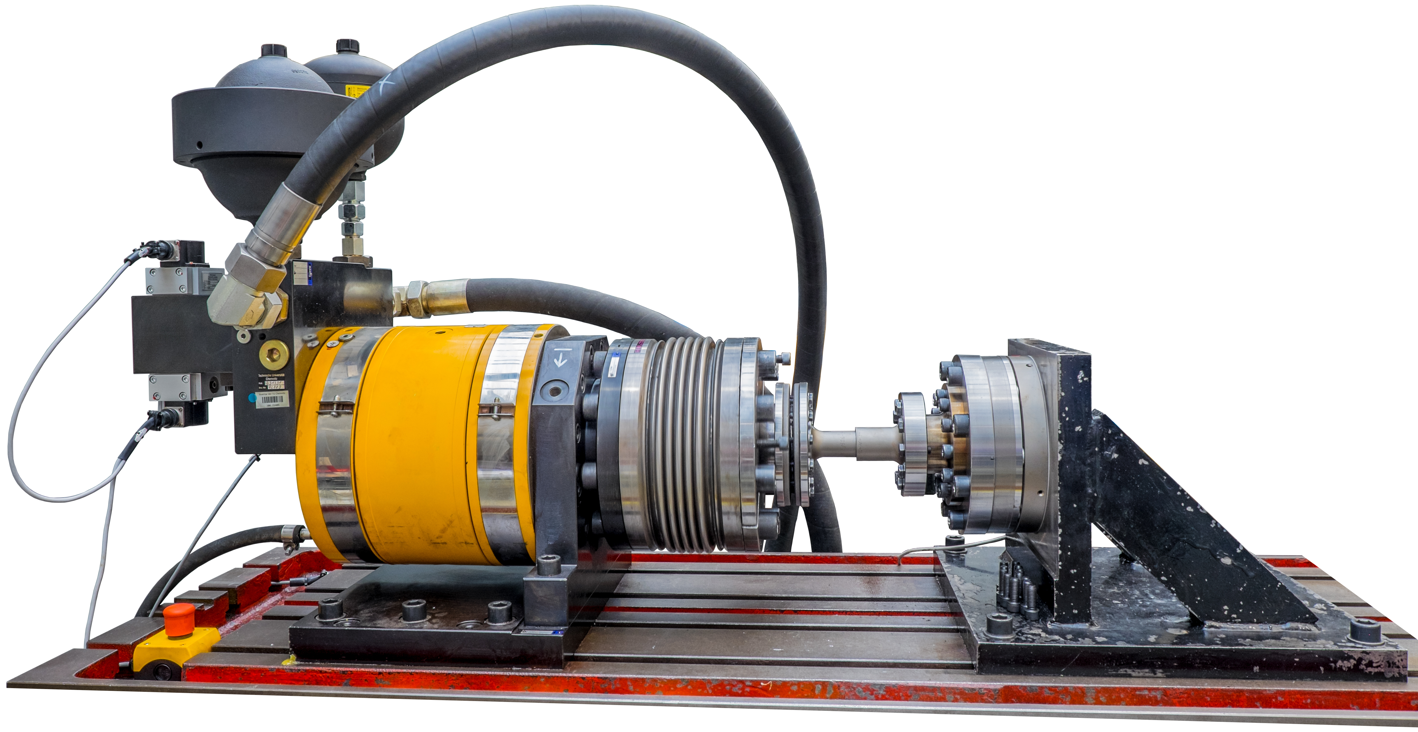

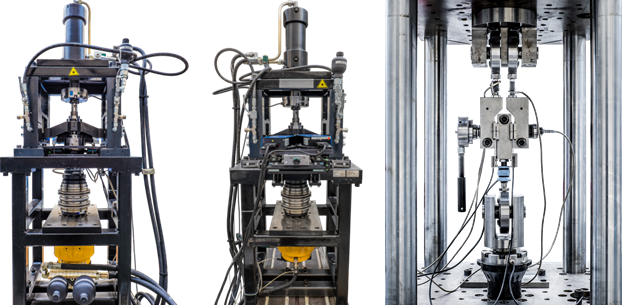

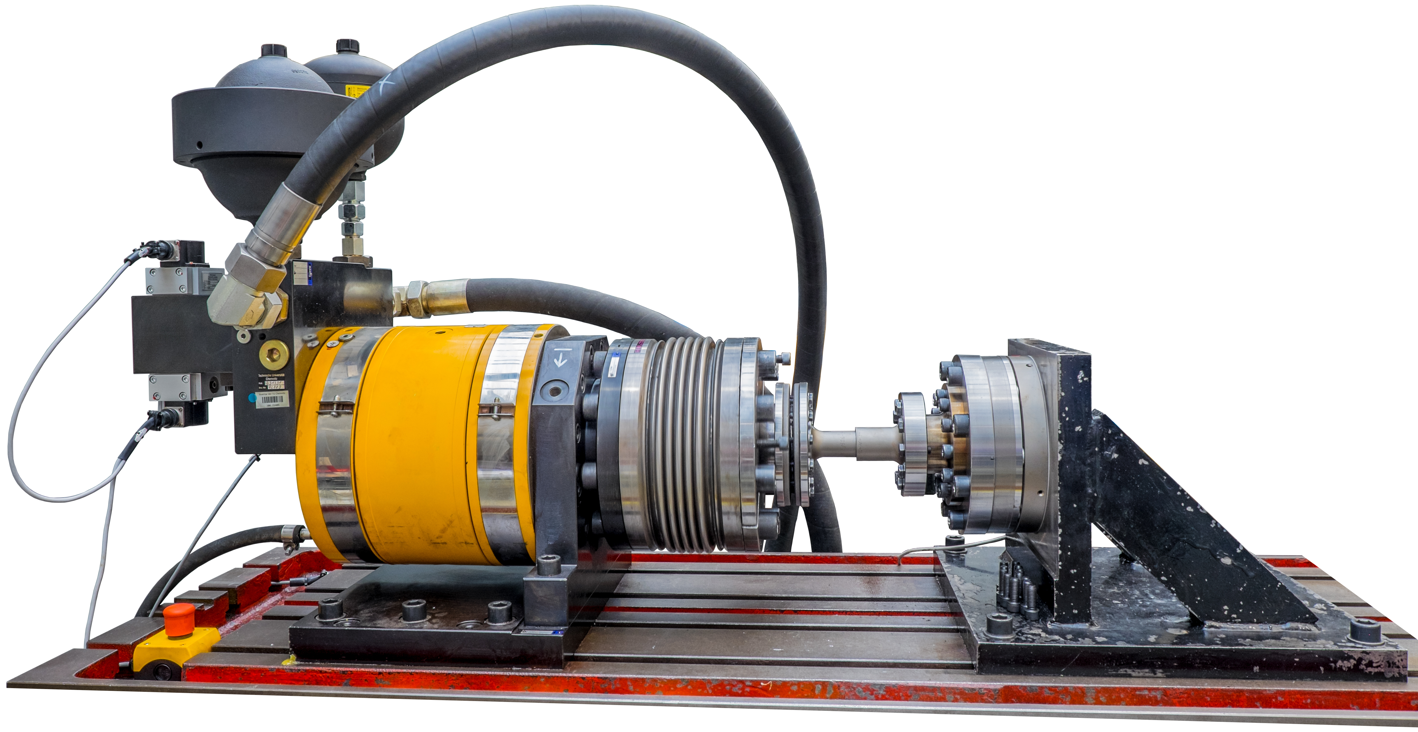

The experimental model investigations are carried out on laboratory test rigs under torsion and transverse-force loading. Full-scale component investigations are performed on the universal rotary cylinder test rig.

Hydraulic Friction Coefficient Test Rig HRP2500 Test fixture for friction-coefficient tests

Hydraulic Rotary Cylinder Test Rig HDZ8000

4 Projects