Friction Corrosion

Interdisciplinary research between tribology and strength; strength assessment of joints at risk of fretting-fatigue fracture

1 General description

2 Research focus

3 Tools

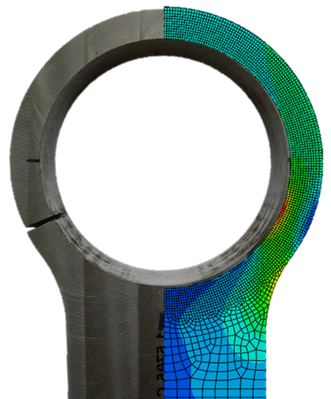

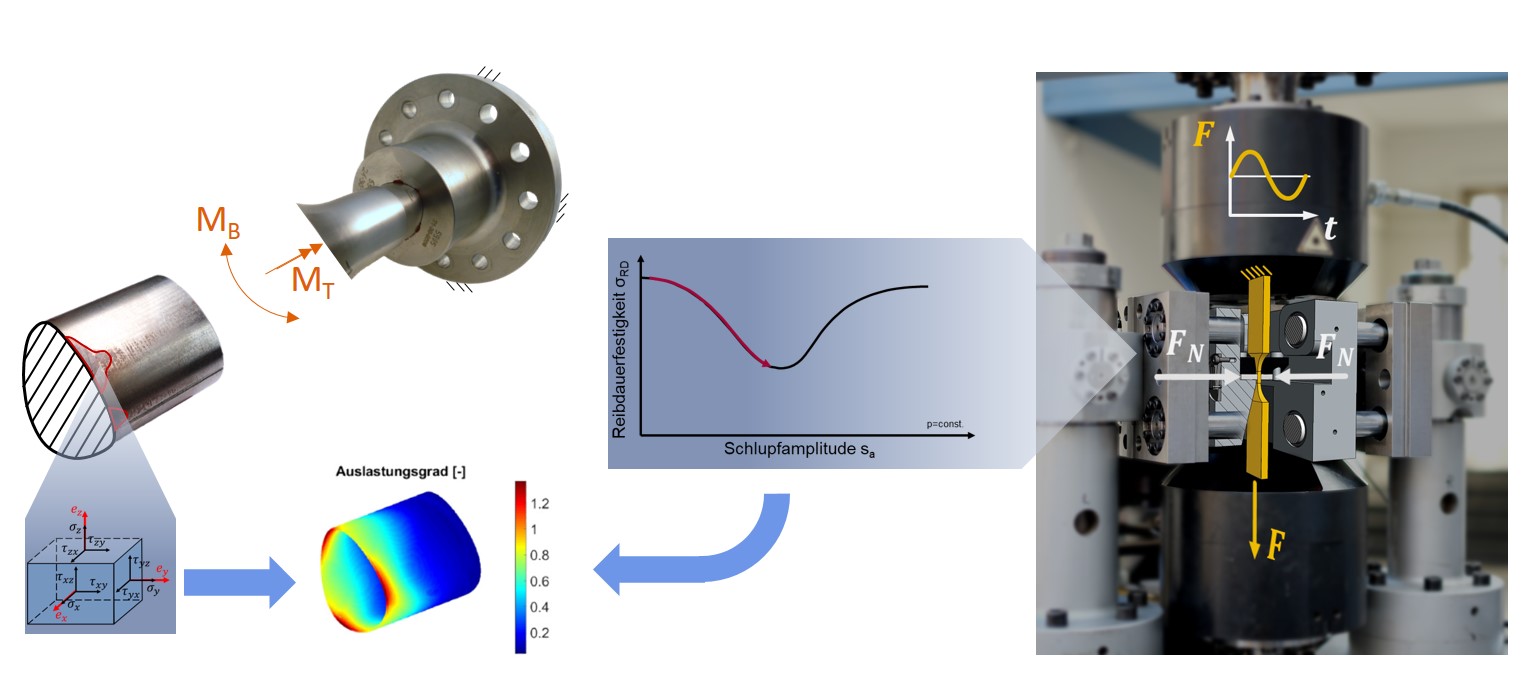

Conversion of the system-specific nominal-stress-based fretting-fatigue strength into a local stress state by means of contact simulation, taking into account the experimental friction values as well as the measured motion sequences between the contact partners. The simulations are carried out with the FE software ABAQUS.

4 Projects

Local strength assessment of fretting fatigued components using the example of shaft-hub connections

| Funding agency: | AiF |

| Research association: | FVA |

| Duration: | 27 Months |

| Start time: | Jan 2023 |

| Editor: | Denny Knabner |

| Further Information: | FVA-no.: 983 I |

The local tribological parameters slip amplitude and pressure are decisive for the evaluation of the fretting fatigue. Since these cannot be determined analytically for every application, dimensioning with nominal stress-based approaches such as DIN 743 or FKM guideline is not possible. However, considering the aspects of lightweight construction and the economic use of material resources, a dimensioning of the components adequate to the real degree of utilisation is required. The present project tries to meet this demand by developing a local calculation concept for the evaluation of the fretting fatigue, which takes into account the real tribological load condition. Within the scope of the planned project, fatigue strength tests of fretting-corrosive damaged key and polygon connections will be evaluated. For this purpose, the test series will be numerically simulated. The determined local tribological stress conditions are reproduced on the laboratory model and the slip-specific uniaxial comparative fatigue strengths are determined by simulation. By comparing the local equivalent stress of the WNV with the corresponding slip-specific equivalent fretting fatigue strength (both determined with the same equivalent stress hypothesis), the local degree of utilisation is obtained. By validating different hypotheses, the most accurate one can be found, which shows the smallest deviation from the degree of utilisation over all test series. The development of a generally valid and standardisable calculation concept requires comprehensive experimental validation. For SMEs, these can only be financed to a limited extent. Therefore, the project and its transfer of results make it possible to make the results accessible to SMEs as well. The resulting concept will be processed and documented in a guideline in such a way that access via established FE programmes is also possible for SMEs.