Radial Journal Bearings

Investigation in all areas – solid, mixed, and fluid friction: simulation, tolerancing, manufacturing, and coating

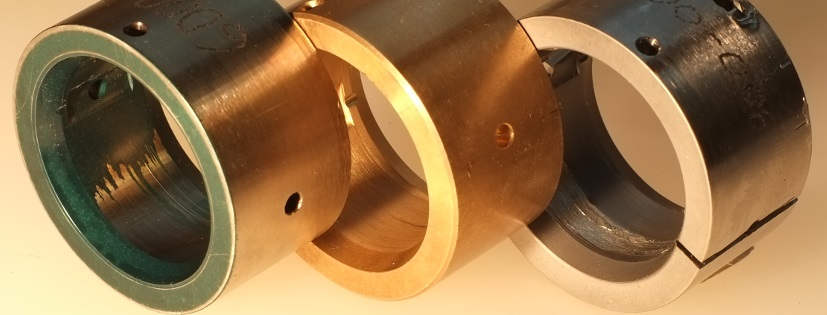

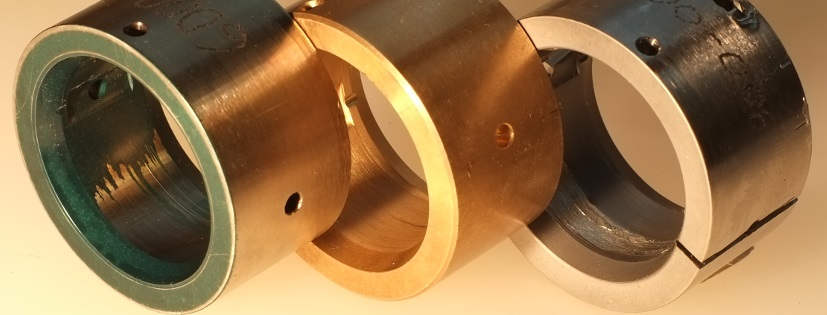

Plain bearings are guiding elements that realize a defined relative motion between two surfaces moving tangentially to each other. Force transmission occurs either through the solid body itself (solid contact) or via an intermediate medium (hydrodynamics).

1 General description

Growing ecological and economic pressure leads to ever higher and more complex stresses in the development of plain bearings. Research at the institute therefore focuses primarily on the investigation and development of alternative sliding materials and the influence of geometric deviations. The main focus is on wear behavior under a wide range of operating conditions (particles, mixed friction, hydrodynamics).

2 Research focus

Evaluation, qualification, and estimation of wear in plain bearings in the areas of hydrodynamics, mixed friction, and dry/solid friction. In addition to load, geometry, and material, various influencing factors—such as layer structure, form deviations, and surface finish—are central to the investigations. Accompanying material optimization and new developments are also key research topics.

3 Tools

Simulation with ALP3T coupled with ABAQUS and visualization with Matlab to analyze structural deformations.

The example shows a roundness deviation in the form of a uniform thickness with orientation changing from 0° to 120°. Shown are the pressure and temperature profiles.

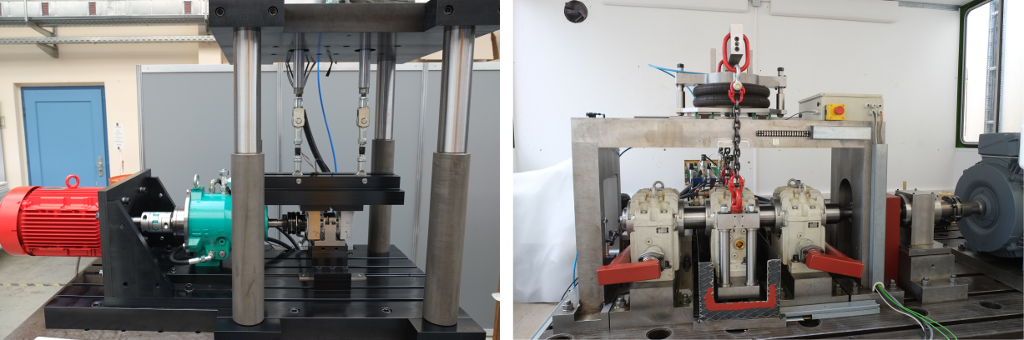

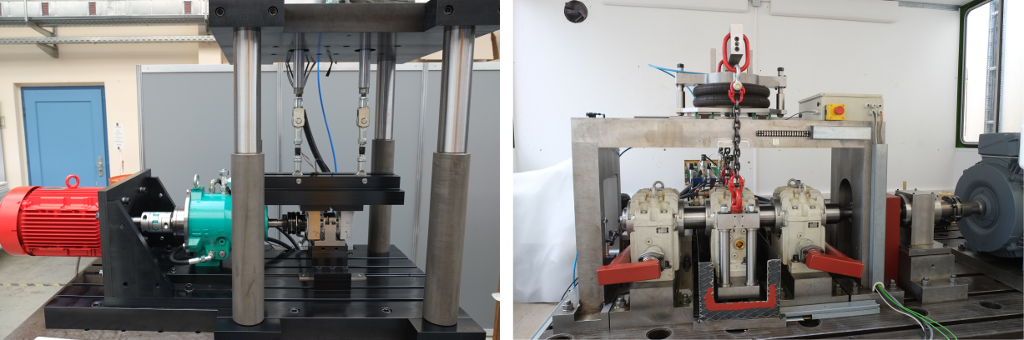

Validation of simulations through tests on the

GLP30 and GLP110 test benches. Furthermore, the tribological properties and performance of the plain bearing system are evaluated.

4 Projects