Keynotes and Program at ELEC 2024

Keynotes

John Bicheno

Lean Education

Lean education takes many forms, some more successful than others. John has been exploring new ways to bring the Lean message home with undergrad students, executive students and lean practitioners. One issue is that many business students see Lean, and wider operations management, as secondary to their prime interests in other management areas. This is relevant because some of those business students will eventually be influential in Lean implementations. The aim of the presentation is to stimulate discussion amongst ELEC attendees.

Bio: John Bicheno is Emeritus Professor of Lean Enterprise at the University of Buckingham. For 15 years he was course director of the MSc in Lean Operations at Lean Enterprise Research Centre (LERC), Cardiff Business School. This hands-on executive program was the first Masters in Lean in the world. John is perhaps best known as the author of The Lean Toolbox (with Matthias Holweg and now in its 6th edition), Human Lean (with Noel Hennessey), and The Lean Games and Simulations Book. During the 1980s he was Associate Professor of Industrial Engineering at the University of the Witwatersrand, Johannesburg during which time he began exploring Lean/TPS with Toyota South Africa. He is still learning.

Nadja Böhlmann

Hands-on Lean and where we might've gotten it wrong

Scrum has its own framework, Lean has a box of chocolate with endless opportunities. Lean is considered the result of the Toyota Production System. Bob Emiliani writes: "TPS is not a toolbox. It is not a set of lean tools like Just-in-Time, 5S, kanban, etc. TPS is a highly developed production system in which all elements interact to form a smoothly functioning whole. At the same time, this system aims to support and encourage people to continuously improve the processes they work with. Unfortunately, many books dealing with lean production promote the misconception that TPS is a collection of tools to make production processes more efficient. This completely misses the point of these instruments as well as the concept of putting people at the centre." James Womack himself said at a Lean Conference in Helsinki 2019 that he is "surprised that Lean is still considered as window dressing." The market is full of "5S"-Gurus, selling only one tool or companies that focus on Shopfloor Management only. Many are missing the holistic system authors such as Bob Emiliani are describing.

I am partially on the "consumer side" of Lean and on the consultancy side. The gap between theory and reality in some companies of the German industry cannot be wider. As long as there are companies that are not allowing improvements below 10.000 €, we're not even close to fully understanding what "Lean" is. Where is the theory wrong, where was the first generation of "Lean"-Experts in Germany wrong? Where are we still wrong?

Bio: From the German Armed Forces to Process and Lean Expert. An army officer who is entering the field of process optimisation? Sounds unexpected, but that’s precisely what I am. In the German Armed Forces, everything works with clear structures, standards, and rules. I learnt to train people, motivate them and took responsibility for a large team. Here I was not only a trainer, but also head of department of a logistics unit and head of training for further educative programmes. These formative years showed me that my true strength lies in training, leadership, and strategy development. My professional journey after the German Armed Forces was shaped by various stations, which brought me a decisive insight: clear and flowing processes are at the heart of a successful organisation. Nadja currently works as a Manager of a Lean department in two production sites at an automotive supplier for electrification and powertrain solutions. She herself warns top managers not to start with kaizen or Lean if they do not realise beforehand that this step of cultural change will consume a lot of energy and attention. "If you are not prepared to accept all this, then don't start with Lean at all and don't think any further about running a sustainable and growth-orientated company!" Nadja Böhlmann has found her own company "The Kaizen Profiler" in 2021 and also supports other companies in the industry in this mission. She is also a moderator at specialist conferences and a speaker on international stages.

Peter Hines

The Future of Lean

Lean as a term has been in use for over 30 years and has evolved from a simple collection of tools, to a sophisticated approach used by many organisations across the world. It continues to evolve, some believe into a theory. Over the last two decades two approaches, agile and Industry 4.0, have also gained a considerable following. This key note talk looks at the future of lean both with its further evolution into the leadership and human resource areas as well as in adjusting to the dislocating effects of Industry 4.0. It considers how a future theory should add to the existing scientific thinking encompassed within the Toyota Way, with contributions from behavioural science, neuroscience and psychology. In addition the session will look at the practical future for Lean in terms of what will it look like for industry and what the role of universities will be in this future.

Bio: Professor Peter Hines, was the Co-Founder of the Lean Enterprise Research Centre at Cardiff Business School. LERC grew to be the largest academic research centre in lean globally. He has undertaken extensive research into Lean and written or co-written twelve books including Shingo Prize winning books "Staying Lean", "Creating a Lean & Green Business System" and "The Essence of Excellence". His latest book "Why Bother" was published in 2022 and received Shingo Publication Award in May 2023. Peter now runs the Enterprise Excellent Network providing European based forms with on-site benchmarking, learning and networking opportunities. He also continues his academic links with work in the Lean/Industry 4.0 and Lean/People spaces and is a Visiting Professor at South East Technological University and Faculty Fellow with The Shingo Institute at Utah State University.

Constantin May

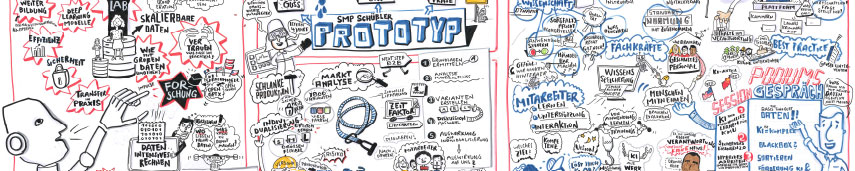

Ten Years of Lean: A Retrospective on the Evolution of Lean Management, its Teaching, and the Growth of the Lean Educator Conference

In "Ten Years of Lean: A Retrospective on the Evolution of Lean Management, its Teaching, and the Growth of the Lean Educator Conference" celebrates a decade of developments in lean management. This keynote provides an overview of the advances in lean methodology, its teaching, and the role of the Lean Educator Conference as a meeting place for innovation and exchange. The milestones and challenges of the last ten years will be highlighted and a look at future trends will be taken. This keynote is a tribute to the community that lives and teaches Lean and a look at how we can equip ourselves for the challenges of the coming years.

Bio: Professor May earned his degree in Industrial Engineering from the Technical University of Kaiserslautern, followed by a stint as a business consultant at IDS Scheer AG. After serving as a research assistant at the Faculty of Business Administration in Ingolstadt, he completed his doctorate on the application of Artificial Intelligence in production at the Technical University of Kaiserslautern. Subsequently, Professor May held various leadership roles in the automotive sector, including extended periods in Asia. Since 1999, he has been teaching and conducting research in Lean Management, Production Management and Logistics at Ansbach University of Applied Sciences. As the Academic Director, he has been instrumental in the success story of CETPM since its inception in 2005. Professor May is a thought leader, a prolific author of multiple books, the publisher of the "Deutscher Management Verlag", and a sought-after speaker both domestically and internationally.

Eivind Reke

Learning in Lean - Searching for the Kaizen Spirit under the Northern Lights

Lean is the alternative business model of our time. Its customer first, problem-based approach to business growth aligned with try-and-see people development makes it a humanistic approach to running a company, where people take responsibility for the changes they make, on every level. Lean has both a soft side and a hard side ? the first through respect for people and belief in their potential, and the latter through a relentless focus on technical learning and development, through challenge, problem, kaizen now! Since 2018 Eivind Reke has travelled and traversed the Scandinavian landscape, visiting numerous organizations, searching for the elusive Kaizen Spirit that brings lean to life, and from 2020 to 2023 participated in two different Norwegian research projects that explored lean as a learning system. In this keynote we will dive deeper into what makes lean a unique approach to running a business and explore what learning really means in lean.

Bio: Eivind Reke is a Research Manager at SINTEF Manufacturing, He is co-author of the award-winning book and LEI bestseller "The Lean Sensei" and writes regularly for planet-lean.com about Lean in the Nordics. Eivind holds an MBA in International Management where he wrote his dissertation about Lean and its impact on financial performance in Norwegian companies. He has held numerous workshops worldwide on lean and people development and has attended numerous lean conferences in Europe as presenter and keynote speaker.

Christoph Roser

MAKE: The History of Manufacturing

Our prosperity is based on efficient manufacturing, and also organizing manufacturing. This efficiency is the result of a long historical beginning with the first manufacturing in the Stone Age, followed by ancient times and the Middle Ages. However, this is only the prelude to the serious upheaval of the Industrial Revolution. With the increasing mechanization the image of production changed drastically within just a few decades. However, this also led to consequent social tensions. Yet, from there Manufacturing took off. From Taylorism to the assembly line of Henry Ford, to computer technology, and to lean manufacturing. What are the lessons learned from History, and what will be the outlook for the future?

Bio: Prof. Dr. Christoph Roser is a worldwide renowned expert for lean production; Toyota, McKinsey, and Bosch Alumni, and professor for Production Management at the Karlsruhe University of applied sciences. He is interested in everything related to lean manufacturing, bottleneck detection and management, as well as historic developments of manufacturing. He blogs about his experiences and research on AllAboutLean.com and published the books "Faster, Better, Cheaper" on the history of manufacturing and "All About Pull Production" going into details of kanban and other pull systems.