Workshops and Demonstrators at ELEC 2024

There will be several workshops on both days. A detailed schedule together with information how to register will be provided latest in August 2024. During the coffee breaks on Thursday September 26 and Friday September 27, there will be also the opportunity to visit different demonstrators. Currently, we plan for the following.

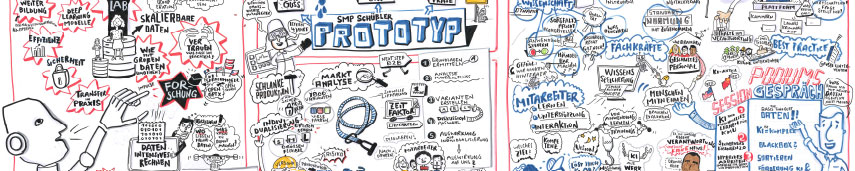

Workshops at ELEC 2024

Practical Bottleneck Detection

In a 2hrs-workshop you will understand the behavior of bottlenecks, with particular focus on shifting bottlenecks using simulation games. Within a group of 10-20 people we will see why commonly used methods in industry are often flawed. A practical bottleneck detection for flow lines will be introduced, the bottleneck walk. The effect of fluctuations will be investigated. A series of possible actions to manage bottlenecks will be presented.

Moderators: Christoph Roser, Jochen Roser

Playing seriously: developing strategic production management perspectives with a serious play approach

In a 2hrs-workshop you will get to know Lego® Serious Play® – a method for “facilitated thinking”. Within a group of 8-10 people we will develop a joint vision on how to successfully integrate humans into smart production systems. Lego® Serious Play® supports communication, teamwork and complex problem solving. Experience this unique technique and let your hands do the thinking work. “The answer is in the system” – let’s reveal it!

Moderators: Ralph Riedel, Luise Weißflog

From the sensor to the user – How do get information from processes and machines?

In our compact 3-4hrs workshop you will learn how data in production systems can be efficiently prepared, processed, recorded, and visualized all the way from the sensor to the user. In a small group of 8-10 participants, we will dive into the world of open-source software and hardware and use it to develop practical solutions for digital data processing. The workshop combines theory with practical examples from our experimental and digital factory lab (EDF), and teaches skills that you can integrate directly into your work. Learn how to use simple technologies to solve complex problems and how to present data in a visually appealing way.

Moderators: Frank Börner, Daniel Fischer, Hendrik Unger

Demonstrators at ELEC 2024

AutoID with AI - intelligently recognize components

The demonstrator provides user support through image classification of assemblies to automatically compare the picked components with the order. A single-board computer optimized for the efficient execution of AI algorithms is used. The camera image evaluation and classification of objects in real time reduces the frequency of errors in picking activities. An operator can configure a product in a product configurator. The AI then compares the components captured by the camera with the created order and indicates which component was recognized and whether it belongs to the order. This use case can also be transferred to quality assurance to identify damage or errors.

Assistance systems and success monitoring with AI

The demonstrator represents an assembly workstation. Users are guided step by step through the assembly process. The component to be selected is indicated by a light signal. In addition, a projection on the work surface shows where a component needs to be attached. During the individual assembly steps, artificial intelligence (AI) checks whether the right component has been installed in the right place. If the AI detects an error, it projects feedback directly into the user's work area.

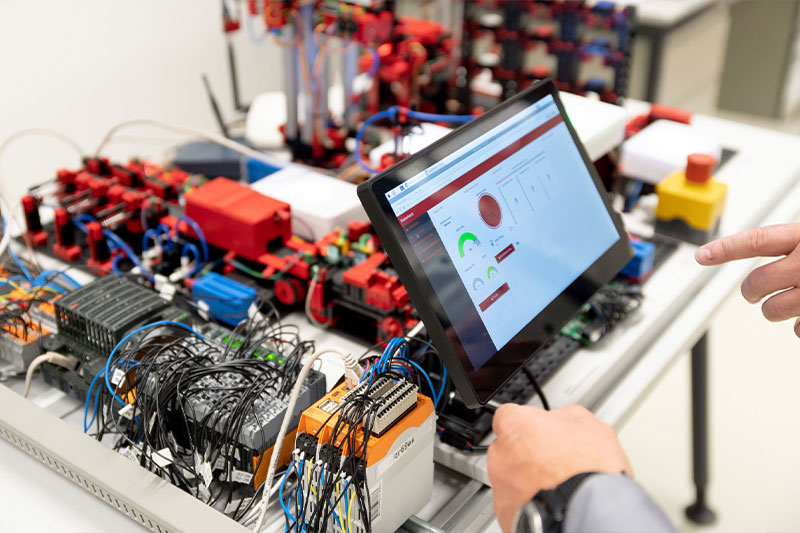

Model Factory 4.0

The demonstrator Model Factory 4.0 shows retrofitting options for automated existing systems. Implemented with Fischer technology, we illustrate all application areas of digitalization, from data collection to data use.

Virtual and augmented reality

Virtual reality or VR offers many new possibilities with which you can improve the presentation of your own products or services. The demonstrator shows the possibilities of virtual and augmented reality and illustrates the concrete benefits for factory planning. A virtual tour of the test environment of the Chair of Factory Planning and Intralogistics with manipulation of objects is possible. Through augmented reality, 3D models of machines are displayed next to “real” miniature models to visually support the layout planning of the systems.

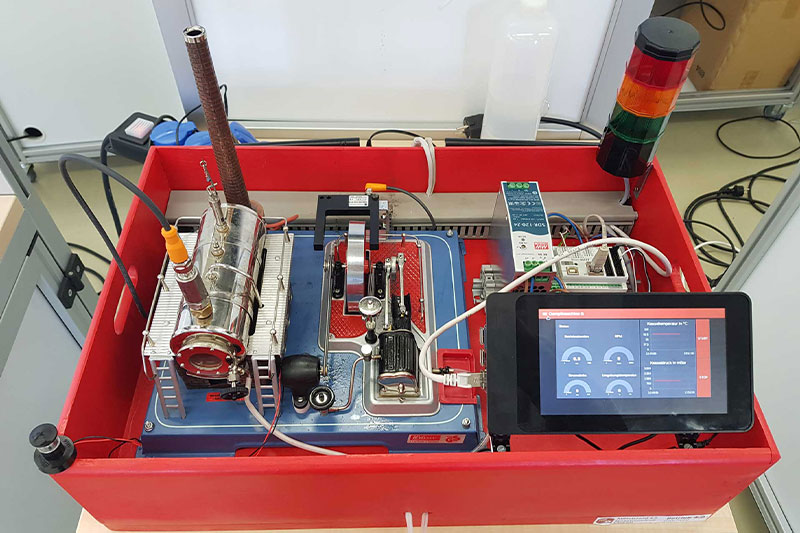

Retrofit steam engine

A conventional steam engine was retrofitted using sensors to make it Industry 4.0-ready. This is an example of the topic of digital retrofit, which enables existing machines to be used for longer even in times of Industry 4.0.