Flexible Assembly through integrated assembly sequence planning (programming)

Flexible Assembly

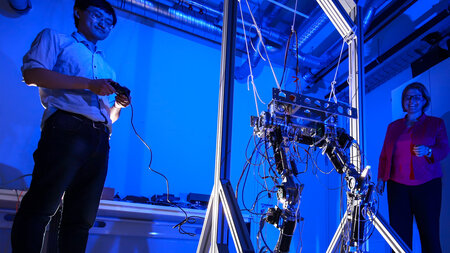

Automated assembly planning allows tasks to be broken down into individual steps. A planning control system creates assembly plans based on geometrical/ physical calculations and conditions. Each step in the assembly plan represents one individual task that is communicated to the robot control; so-called error robust skills execute each individual task found in the assembly plan. At the professorial chair, a domain-specific language (LightRocks) for skills has been developed and results in sensitive assembly tasks that are programmed and stored in its very own library. Every skill therefore represents entry and exit requirements. Supported by a knowledge-based adaptable algorythm, the needed skills can be selected accordingly and assembled automatically, thus allowing to execute complex tasks through the combination of various individual ones.

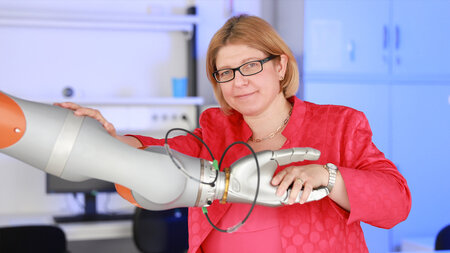

The image below shows an iiwa-light weight robot arm that is able to assemble item profiles in a given order. The order has been defined by human previously. In order to accomplish this task, the robot analyzes the order and starts searching for suitable skills in the skill library. As a result, a robot control programme is created and executed. Due to the described processes, the robot is able to assemble various previously unknown structural components.

Web Service for assembly planning

Fully automated production not only includes automated production and assembly processes, but also an automated generation thereof. In order to optimize assembly processes, one of the aims toward the fully automated production is to reduce the time needed for accomplishing assembly tasks. Reducing time periods needed for assembly preparing tasks and optimizing workcell organisation, will allow more flexibility in a growing world of changing products.

The research project SMErobotics has led to the addition of another web-based interface on the assembly planner. This web service calculates valid assembly sequences for any product using CAD models. Safe and easy to handle browser interfaces will also allow non-experts the usage of this interface.

Utilization:

- Fast generation of potential assembly sequences within the product and developmental phase of the product

- Verification of automated assembly suitability

- Optimizing assembly processes andworkcell organisation

- Integration within existing production environments

Advantages:

- No need for expensive hardware or cost intensive software development

- Independent from industrial area of usage

- Increase in productivity due to reduced product integration time

- Manual assembly planning becomes outdated