Publikationen

Im folgenden sind unsere Veröffentlichungen, dem Jahr entsprechend, aufgelistet.

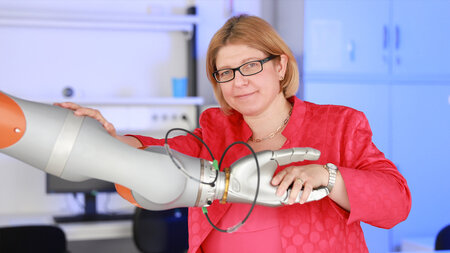

S. Schwarz , U. Thomas Exponential Control Barrier Functions for Enhanced Safety during Safety-Critical Interactions in Telemanipulation Accepted at IEEE Conference on Telepresence, Leiden, Niederlande, 08-10 September, 2025

Telemanipulation is increasingly applied in many applications. Safety is a crucial aspect for interactions of the follower with humans or the environment. This work presents a mechanism to improve safety during these interactions. This approach creates a safe set for the position of the follower using only information about the location of the desired interaction and the direction from which the robot has to approach this interaction. Utilizing exponential control barrier functions (ECBF) restrains the motion when the follower is approaching the boundary of the safe set but enables free motion within. The major benefit compared to compliant control or virtual fixtures is that the follower stays in this region independently of user inputs. A design concept for such an ECBF is proposed that provides high adaptability for task-specific adjustments. The influence of the introduced design parameter is shown. In this work, the algorithm is tested on a physical telemanipulation system using a static interaction scenario. The experiment demonstrates the potential of this approach. Although the robot violates the defined constraint on average by −0.703mm, this approach offers a real-time capable extension for existing telemanipulation systems for safety-critical interaction tasks.

n.a.

C. Gaebert, U. Thomas

Dual-Arm Neural Motion Planning using Action Chunking Transformers

Published in IEEE-RAS 24th International Conference on Humanoid Robots (Humanoids), Seoul, Korea, September 30 to October 2, 2025

DOI: 10.1109/Humanoids65713.2025.11203021

Deploying humanoid robots in everyday environments requires rapidly generating coordinated and collision-free motions for two arms. Despite recent advances in global motion planning and trajectory optimization, high-dimensional configuration spaces still pose a significant challenge due to long planning delays. Neural motion planning addresses this shortcoming by leveraging large planning problem datasets to train a motion planning policy. Such a model can then be used online or to seed global planners. In this work, we extend the neural motion planning approach to a dual-arm setting and thus generate motions in a 14-dimensional joint space. The proposed method is based on a transformer architecture and combines proprioceptive and geometric information in the form of point clouds to predict chunks of joint-space actions. In contrast to previous approaches, we use recent advances in imitation learning for fast point cloud tokenization. We show the performance of our model in simulation and provide insights for deploying it on a real robot. In our experiments, we use the model as a motion planner and for seeding a state-of-the-art trajectory optimizer. Our results show the advantage of transformer-based neural motion planning and its positive impact on the success rates of traditional solvers.

@INPROCEEDINGS{11203021, author={Gaebert, Carl and Thomas, Ulrike}, booktitle={2025 IEEE-RAS 24th International Conference on Humanoid Robots (Humanoids)}, title={Dual-Arm Neural Motion Planning Using Action Chunking Transformers}, year={2025}, volume={}, number={}, pages={776-782}, keywords={Point cloud compression;Robot kinematics;Imitation learning;Humanoid robots;Propioception;Transformers;Manipulators;Tokenization;Planning;Trajectory optimization}, doi={10.1109/Humanoids65713.2025.11203021} }

C. Bandi , U. Thomas

Action Recognition via Multi-View Perception Feature Tracking for Human-Robot Interaction

Published in Robotics, 14(4), 53, an Open Access Journal by MDPI,

This article belongs to the Special Issue Human–AI–Robot Teaming (HART), 19 April, 2025

DOI: 10.3390/robotics14040053

Human–Robot Interaction (HRI) depends on robust perception systems that enable intuitive and seamless interaction between humans and robots. This work introduces a multi-view perception framework designed for HRI, incorporating object detection and tracking, human body and hand pose estimation, unified hand–object pose estimation, and action recognition. We use the state-of-the-art object detection architecture to understand the scene for object detection and segmentation, ensuring high accuracy and real-time performance. In interaction environments, 3D whole-body pose estimation is necessary, and we integrate an existing work with high inference speed. We propose a novel architecture for 3D unified hand–object pose estimation and tracking, capturing real-time spatial relationships between hands and objects. Furthermore, we incorporate action recognition by leveraging whole-body pose, unified hand–object pose estimation, and object tracking to determine the handover interaction state. The proposed architecture is evaluated on large-scale, open-source datasets, demonstrating competitive accuracy and faster inference times, making it well-suited for real-time HRI applications.

@Article{robotics14040053,

AUTHOR = {Bandi, Chaitanya and Thomas, Ulrike},

TITLE = {Action Recognition via Multi-View Perception Feature Tracking for Human–Robot Interaction},

JOURNAL = {Robotics},

VOLUME = {14},

YEAR = {2025},

NUMBER = {4},

ARTICLE-NUMBER = {53},

URL = {https://www.mdpi.com/2218-6581/14/4/53},

ISSN = {2218-6581},

ABSTRACT = {Human–Robot Interaction (HRI) depends on robust perception systems that enable intuitive and seamless interaction between humans and robots. This work introduces a multi-view perception framework designed for HRI, incorporating object detection and tracking, human body and hand pose estimation, unified hand–object pose estimation, and action recognition. We use the state-of-the-art object detection architecture to understand the scene for object detection and segmentation, ensuring high accuracy and real-time performance. In interaction environments, 3D whole-body pose estimation is necessary, and we integrate an existing work with high inference speed. We propose a novel architecture for 3D unified hand–object pose estimation and tracking, capturing real-time spatial relationships between hands and objects. Furthermore, we incorporate action recognition by leveraging whole-body pose, unified hand–object pose estimation, and object tracking to determine the handover interaction state. The proposed architecture is evaluated on large-scale, open-source datasets, demonstrating competitive accuracy and faster inference times, making it well-suited for real-time HRI applications.},

DOI = {10.3390/robotics14040053}

}

L. Talebsafa, C. Gaebert, U. Thomas Conservative Q-Learning for Manipulation Skills using Real World Data Accepted at 1st German Robotics Conference, Nürnberg, Germany, 13-15 March, 2025

Learning robot skills from a limited number of human demonstrations can enable more flexibility in automation and service robotics. To this end, Offline Reinforcement Learning is a promising approach as it aims to learn a meaningful policy from a fixed dataset without online interactions. However, one challenge in this approach is distributional shifts between the learned and behavior policies that lead to overestimating the value of out-of-distribution actions. Several methods exist that introduce conservatism into the value estimation to mitigate this problem. However, they are often evaluated on expert datasets in simulation using proprioceptive data. In this work, we explore their applicability on a simulated and a real robot pouring task. We thus provide insights into the performance of such methods under imperfect conditions such as noisy human demonstrations or image noise.

n.a.

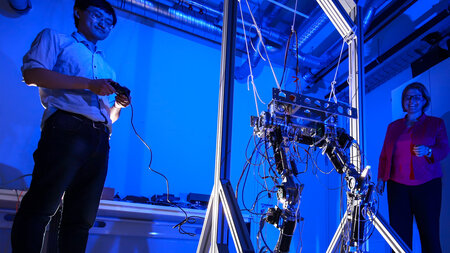

K. Kitz, H. Zhu, J. Zhu, U. Thomas Learning Stable Gait Patterns and Directional Commands for Biped Forrest with Elastic Joints and Closed Kinematic Elements Accepted at 1st German Robotics Conference, Nürnberg, Germany, 13-15 March, 2025

In this work, we present an approach to reliably learn stable gait patterns for a self-designed biped robot with Reinforcement Learning (RL) in the simulation environment Mujoco. For that we designed a model of the robot, which captures its kinematic structure, including elastic components and closed kinematic structures. The reward function, as well as the agents observation, is based on a clock signal which is a key component to learn symmetrical, stable and humanlike gait patterns with multiple RL algorithms reliably and fast. To make the biped robot turn, we follow a multi-task-phase approach, where we separate between phases of straight walking, turning and transition phases.

n.a.

S. Schwarz , U. Thomas Safety and usability in telemanipulated human-robot interactions Accepted at 1st German Robotics Conference, Nürnberg, Germany, 13-15 March, 2025

Safety is a critical aspect whenever robots interact with humans. This also applies to the field of telemanipulation, where the operator might not be fully aware of the remote surroundings. Thus, improvements are necessary to enable telemanipulation in various application areas. In this work, we present our previously proposed algorithms to improve safety and usability in telemanipulated human-robot interaction tasks. It includes an interaction force dependent variable impedance controller to build a safety mechanism and a full 6D variable virtual fixture algorithm to increase accuracy in different applications. The results show great improvements in task performance, system safety and mental workload of the operator.

n.a.

S. Schwarz , P. Berger , U. Thomas Low-cost tactile bracelet for flexible haptic feedback in telemanipulation Accepted at 1st German Robotics Conference, Nürnberg, Germany, 13-15 March, 2025

Haptic feedback offers innovative ways to provide information to the operator during telemanipulation tasks. In this work, a low-cost, easy to use tactile bracelet that can be included in existing telemanipulation systems is presented. It consists of up to 8 linear resonant actuators that can be controlled using a ROS2 interface. A user-study with 9 participants was performed to investigate its usability. A position detection accuracy of 88.52 % shows promising results for implementation into a telemanipulation system. Further, a lower limit for the time discrimination during pulse patterns is defined with 0.18s.

n.a.

C. Bandi , U. Thomas

Multi-Modal Multi-View Perception Feature Tracking for Handover Human Robot Interaction Applications

Proceedings of the 20th International Conference on Computer Vision Theory and Applications (VISAPP), Porto, Portugal, 26-28 February, 2025

DOI: 10.5220/0013373800003912

Object handover is a fundamental task in human-robot interaction (HRI) that relies on robust perception features such as hand pose estimation, object pose estimation, and human pose estimation. While human pose estimation has been extensively researched, this work focuses on creating a comprehensive architecture to track and analyze hand and object poses, thereby enabling effective handover state determination. We propose an end-to-end architecture that integrates unified hand-object pose estimation with hand pose tracking, leveraging an early and efficient fusion of RGB and depth modalities. Our method incorporates existing state of-the-art techniques for human pose estimation and introduces novel advancements for hand-object pose estimation. The architecture is evaluated on three large-scale open-source datasets, demonstrating state-of-the-art performance in unified hand-object pose estimation. Finally, we implement our approach in a human-robot interaction scenario to determine the handover state by extracting and tracking the necessary perception features. This integration highlights the potential of the proposed system for enhancing collaboration in HRI applications.

@conference{visapp25, author={Chaitanya Bandi and Ulrike Thomas}, title={Multi-Modal Multi-View Perception Feature Tracking for Handover Human Robot Interaction Applications}, booktitle={Proceedings of the 20th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications - Volume 3: VISAPP}, year={2025}, pages={797-807}, publisher={SciTePress}, organization={INSTICC}, doi={10.5220/0013373800003912}, isbn={978-989-758-728-3}, issn={2184-4321}, }

C. Gaebert, O. Rehren, S. Jansen, K. Jahn, P. Ohler, G. D. Rey, U. Thomas

Effects of Human-Like Characteristics in Sampling-Based Motion Planning on the Legibility of Robot Arm Motions

Published in ACM Transactions on Human-Robot Interaction.

DOI: 10.1145/3714475

Conveying the intended goal of a robot arm motion has been shown to increase the quality of human-robot collaboration drastically. To this end, optimization-based approaches have been proposed that optimize the legibility of a robot's motion. However, they are limited in two ways. First, they are typically not validated in environments with obstacles and narrow passages that require collision-free motion planning. Second, they do not consider the influence of the anthropomorphization process that might be caused by a human-like motion or appearance of the arm. This leads to the question of to what extent the legibility of motions is influenced by these factors. In this work, we study the influence of our previously proposed human-likeness function on the legibility of robot arm motions in the context of sampling-based motion planning. We evaluate it against three other motions: a functional motion, a recorded expert motion, and a legible motion based on a heuristic for the observer's prediction. For this, we conduct an extensive user study with 94 participants. In contrast to other works, we manipulate the robot's appearance and the complexity of the environment. We thus provide insights into how the legibility of robot motions is influenced by human-like characteristics in motion, appearance and restricting workspace conditions. The complete stimulus material used in this work is provided at Link .

@article{10.1145/3714475,

author = {Gaebert, Carl and Rehren, Oliver and Jansen, Sebastian and Jahn, Katharina and Ohler, Peter and Rey, G\"{u}nter Daniel and Thomas, Ulrike},

title = {Effects of Human-Like Characteristics in Sampling-Based Motion Planning on the Legibility of Robot Arm Motions},

year = {2025},

publisher = {Association for Computing Machinery},

address = {New York, NY, USA}, url = {https://doi.org/10.1145/3714475},

doi = {10.1145/3714475},

note = {Just Accepted},

journal = {J. Hum.-Robot Interact.},

month = jan,

keywords = {motion planning, anthropomorphism, legible robot motions}

}

C. Gaebert, U. Thomas

Generating Dual-Arm Inverse Kinematics Solutions using Latent Variable Models

Published in IEEE-RAS International Conference on Humanoid Robots (Humanoids), Nancy, France, 22-24 November, 2024

DOI: 10.1109/Humanoids58906.2024.10769854

Solving the Inverse Kinematics Problem is a fundamental skill for humanoid robots and their interaction with the world. In contrast to industrial manipulators, humanoid robots can simultaneously grasp or push objects with two hands. This calls for generating self-collision-free inverse kinematics solutions for both arms in a minimal time. Recent research in the context of single-arm manipulators utilizes deep generative models to obtain a whole set of feasible solutions. This work investigates their performance on the more complex dual-arm problem. For this, we extend the problem space to a dual-arm setup and learn inverse kinematics solutions providing the two target end effector poses as a conditional variable. We propose an approach based on Conditional Variational Autoencoders and investigate the trade-off between model size, accuracy, and its benefit when being used for seeding a numeric solver. In this context, we also evaluate the influence of flexible learning-based priors against fixed Gaussian priors. Our approach can initialize the solver within 1ms and drastically increase the number of returned solutions. The results show that even less accurate models can drastically increase the performance of a numeric solver while yielding significantly shorter solving times compared to a state-of-the-art flow-based method.

@INPROCEEDINGS{10769854, author={Gaebert, Carl and Thomas, Ulrike}, booktitle={2024 IEEE-RAS 23rd International Conference on Humanoid Robots (Humanoids)}, title={Generating Dual-Arm Inverse Kinematics Solutions using Latent Variable Models}, year={2024}, volume={}, number={}, pages={373-380}, keywords={Accuracy;Humanoid robots;Kinematics;End effectors;Numerical models;Context modeling}, doi={10.1109/Humanoids58906.2024.10769854} }

S. Schwarz, U. Thomas

6D Variable Virtual Fixtures for Telemanipulated Insertion Tasks

Published in IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 2024

DOI: 10.1109/IROS58592.2024.10801971

Telemanipulation enables humans to perform tasks in dangerous environments without exposing them to any risk. The COVID-19 pandemic sadly showed, that these environments can also include the treatment and interaction with infected patients. Since human-robot interactions demand for low interaction forces yet high precision, telemanipulation often results in a high mental workload for the operator. To overcome this, we present a virtual guidance approach to perform telemanipulated insertion tasks. A nasopharyngeal swap sampling procedure is taken as use case. We extend our previously presented approach by adding an additional position fixture, introducing distance-dependent variable stiffness values and guaranteeing stability using energy tanks. Based on RGB-D data, the operator is guided towards a desirable insertion line while approaching the nostril. The distance-dependent stiffness values increase the smoothness of the fixture. Since variable stiffness values can result in unstable behavior, energy tanks for the fixtures are introduced. Experiments show the improvements compared to our previous approach. Further, a comparison between guided and unguided samplings performed by an expert user gives a first impression of the improvements resulting from the fixture.

@INPROCEEDINGS{10801971, author={Schwarz, Stephan Andreas and Thomas, Ulrike}, booktitle={2024 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS)}, title={6D Variable Virtual Fixtures for Telemanipulated Insertion Tasks}, year={2024}, volume={}, number={}, pages={12183-12189}, keywords={Torque;Pandemics;Fixtures;Force;Force feedback;Human-robot interaction;Stability analysis;Vectors;End effectors;Intelligent robots}, doi={10.1109/IROS58592.2024.10801971} }

B. Suryo Kusumo, U. Thomas

Refining Weights for Enhanced Object Similarity in Multi-Perspective 6Dof Pose Estimation and 3D Object Detection

In Proceedings of the 5th International Conference on Deep Learning Theory and Applications, DeLTA, Dijon, France, 2024

DOI: 10.1007/978-3-031-66694-0_19

At the moment, there are increasing trends in using deep learning for 6 Dof pose estimation and 3D object detection. Recognising objects and determining their 3D positioning and orientation in the scene has numerous applications in robotics. However, due to the variety of objects within the real world, the challenge is complicated. They have various 3D shapes, and their appearance on images can be affected by lighting, clutter in the scenery, and occlusions between objects. Matching feature points between 3D models and images are used to solve the challenge of 6-Dof object pose estimation. We propose a hybrid method for 6 Dof and 3D object detection using a modification of the Resnet18 pre-trained model, combined with object matching and the object symmetric method. We conduct experimental tests with video files and a live-view cam. Visualization test variations are carried out on an object in a single perspective view, a single object in a multi-perspective view, a multi-object in a single perspective view, and a multi-object in a multi-perspective view. We evaluated the performance of this hybrid method on 15 types of objects from Linemod (LM) and Linemod Occluded (LM-O) datasets, resulting in a total training loss of 0.0533049 and a total validation loss of 0.0481146. Keywords: Deep learning · 6 Dof pose estimation · 3D object detection

@InProceedings{10.1007/978-3-031-66694-0_19,

author="Kusumo, Budiarianto Suryo

and Thomas, Ulrike",

editor="Fred, Ana

and Hadjali, Allel

and Gusikhin, Oleg

and Sansone, Carlo",

title="Refining Weights for Enhanced Object Similarity in Multi-perspective 6Dof Pose Estimation and 3D Object Detection",

booktitle="Deep Learning Theory and Applications",

year="2024",

publisher="Springer Nature Switzerland",

address="Cham",

pages="310--327",

abstract="At the moment, there are increasing trends in using deep learning for 6 Dof pose estimation and 3D object detection. Recognising objects and determining their 3D positioning and orientation in the scene has numerous applications in robotics. However, due to the variety of objects within the real world, the challenge is complicated. They have various 3D shapes, and their appearance on images can be affected by lighting, clutter in the scenery, and occlusions between objects. Matching feature points between 3D models and images are used to solve the challenge of 6-Dof object pose estimation. We propose a hybrid method for 6 Dof and 3D object detection using a modification of the Resnet18 pre-trained model, combined with object matching and the object symmetric method. We conduct experimental tests with video files and a live view cam. Visualisation test variations are carried out on an object in a single perspective view, a single object in a multi-perspective view, a multi-object in a single perspective view, and a multi-object in a multi-perspective view. We evaluated the performance of this hybrid method on 15 types of objects from Linemod (LM) and Linemod Occluded (LM-O) dataset, resulting in a total training loss of 0.0533049 and a total validation loss of 0.0481146.",

isbn="978-3-031-66694-0"

}

C. Bandi, U. Thomas

Action Conditioned Attention Encoder-Decoder and Discriminator for Human Motion Generation

In Proceedings of the 5th International Conference on Deep Learning Theory and Applications, DeLTA, Dijon, France, 2024

DOI: 10.1007/978-3-031-66694-0_16

We present a CVAE-GAN-based architecture for human motion generation with an action-conditioned variational autoencoder and a generative discriminator. In this work, we focus on generating more accurate actions performed by a single person using a conditioned generative model. The primary motivation for this work comes from human-robot collaboration scenarios where a person interacts with the robot using human actions. Our approach consists of a self-attention-based conditional variational autoencoder for reconstructions and a graph network-based discriminator for realistic human motion quality. We evaluate our network on three open-source datasets known as HumanAct12, NTU 120 RGB+D, and Actions in Supermarket Dataset. The extensive experiments show that the presented approach works for various human motions and input representations, such as the SMPL pose parameters, trajectory data, and skeleton joints. We achieve higher accuracy compared to the state-of-the-art methods on all three datasets.

@InProceedings{10.1007/978-3-031-66694-0_16, author="Bandi, Chaitanya and Thomas, Ulrike", editor="Fred, Ana and Hadjali, Allel and Gusikhin, Oleg and Sansone, Carlo", title="Action Conditioned Attention Encoder-Decoder and Discriminator for Human Motion Generation", booktitle="Deep Learning Theory and Applications", year="2024", publisher="Springer Nature Switzerland", address="Cham", pages="259--276", abstract="We present a CVAE-GAN-based architecture for human motion generation with an action-conditioned variational autoencoder and a generative discriminator. In this work, we focus on generating more accurate actions performed by a single person using a conditioned generative model. The primary motivation for this work comes from human-robot collaboration scenarios where a person interacts with the robot using human actions. Our approach consists of a self-attention-based conditional variational autoencoder for reconstructions and a graph network-based discriminator for realistic human motion quality. We evaluate our network on three open-source datasets known as HumanAct12, NTU 120 RGB+D, and Actions in Supermarket Dataset. The extensive experiments show that the presented approach works for various human motions and input representations, such as the SMPL pose parameters, trajectory data, and skeleton joints. We achieve higher accuracy compared to the state-of-the-art methods on all three datasets.", isbn="978-3-031-66694-0" }

H. Zhu, U. Thomas

A Novel Compact Design of a Lever-Cam based Variable Stiffness Actuator: LC-VSA

Published in IEEE International Conference on Robotics and Automation, ICRA, Yokohama, Japan, 2024

DOI: 10.1109/ICRA57147.2024.10610124

Ensuring safe interaction between humans and robots is an important challenge in robotics. In recent years, researchers have developed many different soft robots. One possibility to reach this goal is to integrate mechanical springs into their joints. The forthcoming generation of soft robots will be adaptable for joint stiffness to accommodate various tasks. Consequently, the development of variable stiffness joints (VSA) has become crucial. Among the prevalent approaches for stiffness adjustment, lever mechanisms have been implemented in numerous variable stiffness joints. Nonetheless, the integration of the lever technology into VSA often faces challenges in achieving a compact design. This paper introduces a new mechanically compact design for a novel lever-cam based variable stiffness joint, which has been patent under the grand by the german Patentamt.

@INPROCEEDINGS{10610124, author={Zhu, Hongxi and Thomas, Ulrike}, booktitle={2024 IEEE International Conference on Robotics and Automation (ICRA)}, title={A Novel Compact Design of a Lever-Cam based Variable Stiffness Actuator: LC-VSA}, year={2024}, volume={}, number={}, pages={7070-7076}, keywords={Patents;Actuators;Soft robotics;Task analysis;Springs;Faces}, doi={10.1109/ICRA57147.2024.10610124} }

S. Schwarz, C. Gaebert, B. Nieberle, U. Thomas

Virtually Guided Telemanipulation using Neural RRT-Based Planning

In Proceedings of the 4th IFSA Winter Conference on Automation, Robotics & Communications for Industry 4.0 / 5.0 (ARCI’ 2024), Innsbruck, Austria, 7-9 February 2024

DOI: 10.13140/RG.2.2.20923.18722

Telemanipulation is a widely used approach to safely perform tasks remotely. In doing so, the operator can interact with the world using a robot manipulator. A key challenge is moving the robot in a collision-free manner given only a limited view of the environment. To this end, the authors combine a haptic feedback approach with rapid path planning and gaze tracking. This allows for a guided motion that prevents collisions with the environment while maintaining the necessary degree of flexibility and reactiveness. A Neural RRT-Connect algorithm is used to compute a collision-free motion towards a desired goal pose. A virtual fixture, based on a spring-damper system, is used to generate the force that is applied by the input device. A comparison between guided and fully manual telemanipulation in a supermarket-like scenario shows that the shared control approach reduces the task execution time and improves accuracy and collision avoidance. Finally, the neural planning algorithm proves to be applicable in this scenario by generating optimized paths under a second at a success rate of 100 %.

@INPROCEEDINGS{Schwarz2024, author = {Schwarz, Stephan Andreas and Gaebert, Carl and Nieberle, Benedikt and Thomas, Ulrike}, title = {Virtually Guided Telemanipulation using Neural RRT-based Planning}, booktitle = {Proceedings of the 4th IFSA Winter Conference on Automation, Robotics and Communications for Industry 4.0/5.0 (ARCI 2024)}, year = {2024}, month = {02}, pages = {256-259}, publisher={IFSA Publishing, S. L.}, editor={Prof., Dr., Sergey Y. Yurish}, doi = {10.13140/RG.2.2.20923.18722} }

C. Bandi, U. Thomas

Hand Mesh and Object Pose Reconstruction using Cross Model Autoencoder

In Proceedings of the 19th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications - Volume 4 VISAPP: VISAPP, 183-193, Rome, Italy, 2024

DOI: 10.5220/0012370700003660

Hands and objects severely occlude each other, making it extremely challenging to estimate the hand-object pose during human-robot interactions. In this work, we propose a framework that jointly estimates 3D hand mesh and 6D object pose in real-time. The framework shares the features of a single network with both the hand pose estimation network and the object pose estimation network. Hand pose estimation is a parametric model that regresses the shape and pose parameters of the hand. The object pose estimation network is a cross-model variational autoencoder network for direct reconstruction of an object’s 6D pose. Our method shows substantial improvement in object pose estimation on two large-scale open-source datasets.

@conference{visapp24, author={Chaitanya Bandi. and Ulrike Thomas.}, title={Hand Mesh and Object Pose Reconstruction Using Cross Model Autoencoder}, booktitle={Proceedings of the 19th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications - Volume 4: VISAPP}, year={2024}, pages={183-193}, publisher={SciTePress}, organization={INSTICC}, doi={10.5220/0012370700003660}, isbn={978-989-758-679-8}, issn={2184-4321}, }

S. Schwarz, C. Gaebert, U. Thomas

6D Dynamic Tool Compensation using Deep Neural Networks to improve Bilateral Telemanipulation

2nd Workshop Toward Robot Avatars - IEEE International Conference on Robotics and Automation (ICRA), London, UK, 2023

DOI: Link

Force feedback is a crucial component to improve the accuracy and transparency in telemanipulation. Unfortunately, attached tools distort the measured forces of the force sensor. Thus, a compensation of the static and dynamic forces and torques is desired to estimate the robot’s actual interactions with the environment. Due to the inaccuracy of model-based approaches, this paper presents a model-free approach to estimate the 6D forces and torques resulting from an attached tool to compensate the measurement of the force-torque sensor. We use a deep neural network to achieve this and compare multiple combinations of neuron numbers and inputs with an already existing approach. Experiments on a real telemanipulation setup show that the proposed algorithm has a higher accuracy with mean Euclidean errors of only [0.7307 ± 0.4974] N in force and [0.031 ± 0.02] Nm in torque. The low computation time of 0.12 ms makes it suitable for real-time applications such as telemanipulation.

@INPROCEEDINGS{Schwarz2023, author = {Schwarz, Stephan Andreas and Gaebert, Carl and Thomas, Ulrike}, title = {6D Dynamic Tool Compensation using Deep Neural Networks to improve Bilateral Telemanipulation}, maintitle = {IEEE International Conference on Robotics and Automation (ICRA)}, booktitle = {2nd Workshop Toward Robot Avatars}, year = {2023}, month = {05}, url = {https://www.ais.uni-bonn.de/ICRA2023AvatarWS/contributions/ICRA_2023_Avatar_WS_Schwarz.pdf}, urldate = {2024-02-13} }

H. Zhu, U. Thomas

Mechnical Design of a Biped Robot FORREST and an extended Capture Point based Walking Pattern Generator

Published in Robotics, an Open Access Journal by MDPI, (Impact Factor 4.9), Special Issues on Kinematics and Design V.

DOI: 10.3390/robotics12030082

In recent years, many studies have shown that soft robots with elastic actuators enable robust 1 interaction with the environment. Compliant joints can protect mechanical systems and provide better dynamic 2 performance, thus offering huge potential for further developments of humanoid robots. This paper proposes 3 a new biped robot. The new robot combines a torque sensor-based active elastic hip and 4 a spring-based passive elastic knee/ankle. In the first part, the mechanical design is introduced, and in the 5 second part, the kinematics and dynamics capabilities are described. Furthermore, we introduce a new extended 6 capture-point-based walking pattern generator that calculates footstep positions, which are used as input for the 7 controller of our new biped robot. The main contribution of this article is the novel mechanical design and an 8 extended walking pattern generator. The new design offers a unique solution for cable-driven bipeds to achieve 9 both balancing and walking. Meanwhile, the new walking pattern generator can generate smooth desired curves, 10 which is an improvement over traditional generators that use a constant zero-moment-point (ZMP). A simple 11 cartesian controller is applied to test the performance of the walking pattern generator. Despite the robot is built, 12 all experiments regarding the pattern generator still are in simulation using MATLAB/Simulink. The focus of 13 this work is to analyze the mechanical design and show the capabilities of the robot by applying a new pattern 14 generator.

n.a.

H. Zhu, U. Thomas

An Enhanced Walking Pattern Generator with Variable Height for Robot Locomotion

Published in IEEE 19th International Conference on Automation Science and Engineering (CASE) in New Zealand , 2023

DOI: 10.1109/CASE56687.2023.10260344

In this paper, we introduce a novel walking pattern generator that builds on the divergent component of motion (DCM) techniques for biped robots. The aim is to provide an efficient algorithm for generating robot footstep position while walking . We build a new biped robot Forrest. For this robot, but also applicable for any biped robot, we developed a new gait pattern generator. Our approach involves utilizing segmented zero moment point (ZMP) curves within each step to generate a smoother desired trajectory. By this way we overcome the issue of abrupt acceleration changes experienced when using traditional walking pattern generators with a constant ZMP. Additionally, our generator employs a 3-D divergent component of motion (DCM) curve to plan for variable heights in the center of mass (CoM) trajectory, which is crucial for achieving a walking pattern that resembles human walking. We introduce this new gait generator and show first result on our biped robot.

@INPROCEEDINGS{10260344, author={Zhu, Hongxi and Thomas, Ulrike}, booktitle={2023 IEEE 19th International Conference on Automation Science and Engineering (CASE)}, title={An Enhanced Walking Pattern Generator with Variable Height for Robot Locomotion}, year={2023}, volume={}, number={}, pages={1-7}, doi={10.1109/CASE56687.2023.10260344} }

S. Schwarz, U. Thomas

Vision-based Shared Control for Telemanipulated Nasopharyngeal Swab Sampling

Published in International Symposium on Medical Robotics (ISMR), 2023

DOI: 10.1109/ISMR57123.2023.10130223

Telemanipulation enables people to perform tasks in dangerous environments without exposing them to any risk. This also applies for medical applications. Many infections, such as the SARS-CoV-2 virus, spread over the air and can infect the staff while, e.g., taking samples. This paper proposes a shared control algorithm for a telemanipulation system that enables medical staff to easily perform nasopharyngeal swab samplings from a safe distance while maintaining the safety of the patient. We propose a vision-based virtual fixture approach to guide the operator during the approach towards the nostril. Force feedback and velocity scaling is used to improve dexterity and safety during the sampling. We further prove the stability of the system by introducing an energy tank that ensures passivity at all times. Finally, we test the approach on a real telemanipulation setup and demonstrate the improved usability resulting from the guidance of the shared control.

@INPROCEEDINGS{10130223, author={Schwarz, Stephan Andreas and Thomas, Ulrike}, booktitle={2023 International Symposium on Medical Robotics (ISMR)}, title={Vision-Based Shared Control for Telemanipulated Nasopharyngeal Swab Sampling}, year={2023}, volume={}, number={}, pages={1-7}, doi={10.1109/ISMR57123.2023.10130223} }

C. Geabert, C. Bandi, U. Thomas Grasp Pose Generation for Human-to-Robot Handovers using Simulation-to-Reality Transfer Accepted at 1st International Conference on Hybrid Societies, 2023

Human-to-robot handovers play an important role in collaborative tasks in industry or household assistance. Due to the vast amount of possible unknown objects, learning-based approaches gained interest for robust and general graspsynthesis. However, obtaining real training data for such methods requires expensive human demonstrations. Simulated data, on the other hand, is easy to generate and can be randomized to cover the distribution of real world data. The first contribution of this work is a dataset for human grasps generated in simulation. For this, we use a simulated hand and models of 10 objects from the YCB dataset [Calli et al., 2015]. It can also be easily extended to include new objects. The method thus allows for generating an arbitrary amount of training data without human interactions. Secondly, we combine a generative neural grasp generator with an evaluator model for grasp pose generation. In contrast to previous works, we obtain grasp poses from simulated RGB images which allows for reducing the negative effects of depth sensor noise. To this end, our generator model is provided with a cropped image of the human hand and learns the distribution of grasps in the wrist system. The evaluator then narrows down the list of grasps to the most promising ones. The presented approach requires the model to extract relevant features from images instead of point clouds. A cost-efficient method for generating large amounts of training data is therefore needed. We test our approach in simulation and transfer it to a real robot system.We use the same objects as in the training dataset but also test the generalization capabilities towards new objects. The presented dataset is available for download: https://tuc.cloud/index.php/s/g3noZD7oCqbQR9d.

n.a.

S. Kaden, C. Geabert, U. Thomas Towards Smooth Human-Robot Interaction using Potential Gradient-Based Sampling Accepted at 1st International Conference on Hybrid Societies, 2023

Successful human-robot interaction calls for fast generation of collision-free and optimized motions. To this end, sampling-based motion planning algorithms have been widely used. However, they often require long planning times to achieve optimized motions. While not being a critical issue in traditional industrial applications, planning time delays or poorly optimized motions have very negative effects on human-robot cooperation. Including artificial potential fields in the sampling algorithm can drastically improve the quality and planning time of such methods. Previous works in this direction are often tailored towards minimizing distance costs such as path length. In this work, we propose a heuristic based on potential fields that can also be used with a variety of state cost functions. We demonstrate the effectiveness of our approach using two cost functions related to humanrobot interaction. We achieve drastically improved results in both scenarios. This allows for reducing total planning time and achieving a smoother interaction between human and robot.

n.a.

C. Bandi, U. Thomas

Face-Based Gaze Estimation Using Residual Attention Pooling Network

In Proceedings of the 18th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications - Volume 4 VISAPP: VISAPP, 541-549, Lisbon, Portugal, 2023

DOI: 10.5220/0011789200003417

Gaze estimation reveals a person’s intent and willingness to interact, which is an important cue in human-robot interaction applications to gain a robot’s attention. With tremendous developments in deep learning architectures and easily accessible cameras, human eye gaze estimation has received a lot of attention. Compared to traditional model-based gaze estimation methods, appearance-based methods have shown a substantial improvement in accuracy. In this work, we present an appearance-based gaze estimation architecture that adopts convolutions, residuals, and attention blocks to increase gaze accuracy further. Face and eye images are generally adopted separately or in combination for the estimation of eye gaze. In this work, we rely entirely on facial features, since the gaze can be tracked under extreme head pose variations. With the proposed architecture, we attain better than state-of-the-art accuracy on the MPIIFaceGaze dataset and the ETH-XGaze open-source benchmark.

@conference{visapp23,

author={Chaitanya Bandi. and Ulrike Thomas.},

title={Face-Based Gaze Estimation Using Residual Attention Pooling Network},

booktitle={Proceedings of the 18th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications (VISIGRAPP 2023) - Volume 4: VISAPP},

year={2023},

pages={541-549},

publisher={SciTePress},

organization={INSTICC},

doi={10.5220/0011789200003417},

isbn={978-989-758-634-7},

issn={2184-4321},

}

C. Bandi, U. Thomas

A New Efficient Eye Gaze Tracker for Robotic Applications

Published in IEEE International Conference on Robotics and Automation (ICRA), 2023

DOI: 10.1109/ICRA48891.2023.10161347

Gaze estimation exposes a person’s intention and interaction willingness with a robot, which is an important cue in human-robot collaborative applications to obtain a robot’s attention. With enormous developments in deep learning architectures, convolution-based eye gaze estimation has acquired a lot of attention. Appearance-based methods have shown a significant improvement in gaze accuracy and works in unconstrained environments unlike traditional approaches. We introduce yet another appearance-based gaze estimation architecture in this work, to boost the angular accuracy even further. In this work, we completely rely on face images as eye gaze can be estimated in the case of extreme head pose variations and varied distances.With the proposed architecture, we achieve better than the state-of-the-art accuracy of 3.809◦ on MPIIFaceGaze dataset and 3.96◦ on ETH-XGaze open-source benchmark. In addition, we test the eye gaze tracking in realtime robotic applications like attention grabing, pick and place.

@INPROCEEDINGS{10161347, author={Bandi, Chaitanya and Thomas, Ulrike}, booktitle={2023 IEEE International Conference on Robotics and Automation (ICRA)}, title={A New Efficient Eye Gaze Tracker for Robotic Applications}, year={2023}, volume={}, number={}, pages={6153-6159}, doi={10.1109/ICRA48891.2023.10161347} }

C. Gaebert, S. Kaden, B. Fischer, U. Thomas

Parameter Optimization for Manipulator Motion Planning using a Novel Benchmark Set

Published in IEEE International Conference on Robotics and Automation (ICRA), 2023

DOI: 10.1109/ICRA48891.2023.10160694

Sampling-based motion planning algorithms have been continuously developed for more than two decades. Apart from mobile robots, they are also widely used in manipulator motion planning. Hence, these methods play a key role in collaborative and shared workspaces. Despite numerous improvements, their performance can highly vary depending on the chosen parameter setting. The optimal parameters depend on numerous factors such as the start state, the goal state and the complexity of the environment. Practitioners usually choose these values using their experience and tedious trial and error experiments. To address this problem, recent works combine hyperparameter optimization methods with motion planning. They show that tuning the planner's parameters can lead to shorter planning times and lower costs. It is not clear, however, how well such approaches generalize to a diverse set of planning problems that include narrow passages as well as barely cluttered environments. In this work, we analyze optimized planner settings for a large set of diverse planning problems. We then provide insights into the connection between the characteristics of the planning problem and the optimal parameters. As a result, we provide a list of recommended parameters for various use-cases. Our experiments are based on a novel motion planning benchmark for manipulators which we provide at https://tuc.cloud/index.php/s/aSRXr7gTdLDefH3.

@INPROCEEDINGS{10160694,

author={Gaebert, Carl and Kaden, Sascha and Fischer, Benjamin and Thomas, Ulrike},

booktitle={2023 IEEE International Conference on Robotics and Automation (ICRA)},

title={Parameter Optimization for Manipulator Motion Planning using a Novel Benchmark Set},

year={2023},

volume={},

number={},

pages={9218-9223},

doi={10.1109/ICRA48891.2023.10160694}

}

S. Schwarz, U. Thomas Human-Robot Interaction in Telemanipulation - An Overview Accepted at 1st International Conference on Hybrid Societies, 2023

Teleoperation and haptic telemanipulation is a common solution to perform tasks from a remote distance. It is very suitable and can be used in dangerous or unreachable environments, such as nuclear power plants, space missions or under water. In recent years, especially due to the COVID-19 pandemic, telemanipulation is increasingly used to perform tasks involving other human participants. This paper gives an overview of the state of the art regarding control concepts to improve human-robot interaction on the follower side of a telemanipulation system. In this context, system architectures and shared control approaches are considered. We also present the work done in the Collaborative Research Center 1410 regarding telemanipulation including a safety mechanism as well as two shared control concepts to improve human-likeness, safety and mobility of the follower motion.

n.a.

Y. Ding

Fast Perception-Action Loops with Proximity Sensors for Robotic Manipulators

Dissertation, 2022, September

ISBN: 978-3-8440-8762-8

Proximity sensors attached to the outer shell of robotic manipulators provide fast and occlusion-free perception capabilities of the robot’s nearby environment. They offer a solution towards fenceless collaborative workspaces by closing the gap in perception be- tween (3D depth) cameras and tactile/force sensing. The perception gap occurs at the robot’s close range, where external cameras provide insufficient information due to noise, resolution, and occlusion, and where tactile sensors remain untriggered. This thesis ex- amines the fast perception-action loop of such systems to increase safety with reactive obstacle and collision avoidance motions and proactive adaption for impact attenuation. The loop consists of three elements: proximity perception, reactive motion generation, and the proactive adaption of the robot parameters. The first part of the safety chain shows an on-robot proximity perception system. The concept behind the system is to combine two sensors. Laser-based time-of-flight sensing is used for far-range while capacitive proximity detection covers the blind areas by wide- area detection. A novel custom-designed capacitive proximity sensor is presented that is robust against different grounding conditions of obstacles, a significant issue of con- ventional capacitive proximity sensors. The perception system has characteristic features by providing rich near-field information with a limited quantity of measurement points, minimizing the amount of redundant information, and thus increasing responsiveness. Reactive motions require only a few data points for fast motion generation and benefit from these features, especially for collision avoidance, where instantaneous adjustments of the robot’s trajectory are mandatory. This thesis proposes two methods, one based on finding an avoidance vector with sampling in orthogonal directions towards the obsta- cle and another one by extending quadratic optimization to integrate the avoidance task within optimization constraints. Compared to common repulsive motions for collision avoidance, the proposed motion generators are less restrictive. They make full use of the robot’s redundancy for task retention and provide solutions for multi-obstacle whole-arm obstacle avoidance. The algorithms further focus on evasive motions to bypass obstacles to decrease the risk of the robot freezing problem appearing. A phenomenon in which the robot gets stuck in local minima where it stops before obstacles in an equilibrium state of attraction towards the goal and repulsion from the obstacle. The third part addresses the issue that collisions cannot always be prevented because the required avoidance motion exceeds the robot’s motion capabilities. The last safety layer relies on the anticipation of contacts with proximity sensors to enhance the effectiveness impedance controllers for impact attenuation. The first measure modulates the stiffness of the impedance controllers as required, allowing faster, more accurate motions during regular operation while maintaining safety. A high stiffness setup suppresses positional disturbances during regular operation of the robot for high accuracy. The stiffness de- creases only before impacts with safety as highest priority. The second measure slightly modifies the joint configuration to decrease the effective inertia of the manipulator at the impact point.

@phdthesis{..., month = {September}, author = {Yitao Ding}, series = {Fortschritte der Robtik / Progress in Robotics}, editor = {Ulrike Thomas}, title = {Fast Perception-Action Loops with Proximity Sensors for Robotic Manipulators}, publisher = {Shaker Verlag}, year = {2022}, keywords = {Proximity Servoing; Proximity Perception; Capacitive Proximity Sensors; Reactive Motions; Obstacle Avoidance; Collision Avoidance; Impact Attenuation}, }

C. Bandi, U. Thomas

Regression-Based 3D Hand Pose Estimation for Human-Robot Interaction

Published in Communications in Computer and Information Science book series (CCIS, Volume 1474), 2022

DOI: 10.1007/978-3-030-94893-1_24

In shared workspaces where humans and robots interact, a significant task is to hand over objects. The process of hand over needs to be reliable, a human must not be injured during the process, hence reliable tracking of human hands is necessary. To avoid collision, we apply an encoder-decoder based 2D and 3D keypoint regression network on color images. In this paper, we introduce a complete pipeline with the idea of stacked and cascaded convolutional neural networks and tune the parameters of the network for real-time applications. Experiments are conducted on multiple datasets, with low and high occlusions and we evaluate the trained models on multiple datasets for the human-robot interaction test set.

@InProceedings{10.1007/978-3-030-94893-1_24, author="Bandi, Chaitanya and Thomas, Ulrike", editor="Bouatouch, Kadi and de Sousa, A. Augusto and Chessa, Manuela and Paljic, Alexis and Kerren, Andreas and Hurter, Christophe and Farinella, Giovanni Maria and Radeva, Petia and Braz, Jose", title="Regression-Based 3D Hand Pose Estimation for Human-Robot Interaction", booktitle="Computer Vision, Imaging and Computer Graphics Theory and Applications", year="2022", publisher="Springer International Publishing", address="Cham", pages="507--529", abstract="In shared workspaces where humans and robots interact, a significant task is to hand over objects. The process of hand over needs to be reliable, a human must not be injured during the process, hence reliable tracking of human hands is necessary. To avoid collision, we apply an encoder-decoder based 2D and 3D keypoint regression network on color images. In this paper, we introduce a complete pipeline with the idea of stacked and cascaded convolutional neural networks and tune the parameters of the network for real-time applications. Experiments are conducted on multiple datasets, with low and high occlusions and we evaluate the trained models on multiple datasets for the human-robot interaction test set.", isbn="978-3-030-94893-1" }

H. Alagi, S. Ergun, Y. Ding, T. Philip Huck, U. Thomas, H. Zangl, B. Hein

Evaluation of On-Robot Capacitive Proximity Sensors with Collision Experiments for Human-Robot Collaboration (HRC)

Published in IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 2022

DOI: 10.1109/IROS47612.2022.9981490

A robot must comply with very restrictive safety standards in close human-robot collaboration applications. These standards limit the robot's performance because of speed reductions to avoid potentially large forces exerted on humans during collisions. On-robot capacitive proximity sensors (CPS) can serve as a solution to allow higher speeds and thus better productivity. They allow early reactive measures before contacts occur to reduce the forces during collisions. An open question on designing the systems is the selection of an adequate activation distance to trigger safety measures for a specific robot while considering latency and detection robustness. Furthermore, the systems' actual effectiveness of impact attenuation and performance gain has not been evaluated before. In this work, we define and conduct a unified test procedure based on collision experiments to determine these parameters and investigate the performance gain. Two capacitive proximity sensor systems are evaluated on this test strategy on two robots. This work can serve as a reference guide for designing, configuring and implementing future on-robot CPSs.

@INPROCEEDINGS{9981490,

author={Alagi, Hosam and Ergun, Serkan and Ding, Yitao and Huck, Tom P. and Thomas, Ulrike and Zangl, Hubert and Hein, Björn},

booktitle={2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS)},

title={Evaluation of On-Robot Capacitive Proximity Sensors with Collision Experiments for Human-Robot Collaboration},

year={2022},

volume={},

number={},

pages={6716-6723},

doi={10.1109/IROS47612.2022.9981490}

}

S. Schwarz, U. Thomas

Variable Impedance Control for Safety and Usability in Telemanipulation

Published in IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 2022

DOI: 10.1109/IROS47612.2022.9982118

In recent years, haptic telemanipulation has been introduced to control robots remotely with an input device that generates force feedback. Compliant control strategies are needed to ensure safe interaction between humans and robots. Accurate and precise manipulation requires a stiff setup of the impedance parameters, while safety demands for low stiffnesses. This paper proposes an impedance-based control approach that combines stiff manipulation with a safety mechanism that adapts compliance when required. We introduce three system modes: operation, safety and recovery mode. If the external forces exceed a defined force threshold, the system switches to the compliant safety mode. A user input triggers the recovery process that increases the stiffness back to its nominal value. This paper suggests an energy tank, which limits the change of stiffness to ensure stability during recovering phase.

@INPROCEEDINGS{9982118,

author={Schwarz, Stephan Andreas and Thomas, Ulrike},

booktitle={2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS)},

title={Variable Impedance Control for Safety and Usability in Telemanipulation},

year={2022},

volume={},

number={},

pages={6177-6182},

doi={10.1109/IROS47612.2022.9982118}

}

C. Gaebert, U. Thomas

Learning-based Adaptive Sampling for Manipulator Motion Planning

Published in IEEE 18th International Conference on Automation Science and Engineering (CASE), 2022

DOI: 10.1109/CASE49997.2022.9926609

Fast generation of optimized robot motions is crucial for achieving fluent cooperation in shared workspaces. Established sampling-based motion planning algorithms are guaranteed to converge to an optimal solution but often deliver low-quality initial results. To this end, learning-based methods reduce planning time delays and increase motion quality. Existing methods show promising results for low-dimensional and simulated problems. In the real world, sensor noise or a change of the robot's tool can cause a distributional shift to the training data. An adaptive sampling strategy is thus required to cope with possibly suboptimal samples and ensure fast motion planning in human-robot collaboration. In this work, we present a sampling strategy for fast and efficient manipulator motion planning which is based on a conditional variational autoencoder. We test our model for three optimization objectives: path length in configuration space and workspace, as well as joint limit distances. In contrast to other works, we not only condition our model on the planning problem but also on motion progress. This allows for generating samples in the growth direction of the tree. Using our method, we obtain high-quality initial paths within less than one second of planning time.

@INPROCEEDINGS{9926609,

author={Gaebert, Carl and Thomas, Ulrike},

booktitle={2022 IEEE 18th International Conference on Automation Science and Engineering (CASE)},

title={Learning-based Adaptive Sampling for Manipulator Motion Planning},

year={2022},

volume={},

number={},

pages={715-721},

doi={10.1109/CASE49997.2022.9926609}

}

C. Gaebert, A. Djemal, H. Hellara, B. Ben Atitallah, R. Ramalingame,

R. Barioul, D. Salzseiler, E. Fricke, O. Kanoun, U. Thomas

Gesture Based Symbiotic Robot Programming for Agile Production

Published in IEEE 9th International Conference on Computational Intelligence and Virtual Environments for Measurement Systems and Applications (CIVEMSA), 2022

DOI: 10.1109/CIVEMSA53371.2022.9853686

Agile production lines call for an effective and intuitive way of programming robots. However, traditional approaches rely on providing low-level instructions using either a script-based language or a graphical user interface to export low-level instructions. This, however, can be tedious for assembly tasks. In this work, we present an approach that generates low-level robot control commands from highly abstract communicative hand gestures. In contrast to other works, we use several abstraction layers to generate such commands with as little user input as possible. For this, we use a body-attached multi-sensor setup consisting of a pressure band, a smart glove, EMG and IMU units. Their combined signals define a multi-dimensional vector per time step. We use a Recurrent Neural Network to infer the gesture class from the pre-processed data stream. From these user inputs we generate a set of symbolic spatial relations describing the assembly process. This formal description is then used to select and execute robot skills such as grasping. Hence, we reduce the ambiguity of abstract instructions in several steps and allow for effective gesture-based robot programming. In our work we give insights in defining and detecting such gestures. In addition, we illustrate the functionality of the whole system at real-world examples.

@INPROCEEDINGS{9853686,

author={Gäbert, Carl and Djemal, Achraf and Hellara, Hiba and Atitallah, Bilel Ben and Ramalingame, Rajarajan and Barioul, Rim and Salzseiler, Dennis and Fricke, Ellen and Kanoun, Olfa and Thomas, Ulrike},

booktitle={2022 IEEE 9th International Conference on Computational Intelligence and Virtual Environments for Measurement Systems and Applications (CIVEMSA)},

title={Gesture Based Symbiotic Robot Programming for Agile Production},

year={2022},

volume={},

number={},

pages={1-6},

doi={10.1109/CIVEMSA53371.2022.9853686}

}

H. Zhu, U. Thomas

A Novel Full State Feedback Decoupling Controller For Elastic Robot Arm

Published in IEEE International Conference on Robotics and Automation (ICRA), 2022

DOI: 10.1109/ICRA46639.2022.9812047

In this paper a novel full state feedback approach for control of compliant actuated robot with nonlinear spring characteristics is presented. A multi-DOF elastic robot arm is a multi-input multi-output (MIMO) under-actuated system. By the new novel controller, which is based on motor coordinate transformation and motor inertia shaping, the MIMO system can be converted into a set of decoupled single-input singleoutput (SISO) systems. Using full state feedback controller, we can configurate the poles of each SISO system. The controller is validated by an 3-DOF elastic robot with nonlinear spring characteristics in simulation of MATLAB/Simulink.

@INPROCEEDINGS{9812047,

author={Zhu, Hongxi and Thomas, Ulrike},

booktitle={2022 International Conference on Robotics and Automation (ICRA)},

title={A Novel Full State Feedback Decoupling Controller For Elastic Robot Arm},

year={2022},

volume={},

number={},

pages={3210-3215},

doi={10.1109/ICRA46639.2022.9812047}

}

C. Bandi, H. Kisner, U. Thomas

3D Hand and Object Pose Estimation for Real-Time Human-Robot

Interaction

In Proceedings of the 17th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications - Volume 4: VISAPP, 770-780, 2022

DOI: 10.5220/0010902400003124

Estimating 3D hand pose and object pose in real-time is essential for human-robot interaction scenarios like handover of objects. Particularly in handover scenarios, many challenges need to be faced such as mutual hand-object occlusions and the inference speed to enhance the reactiveness of robots. In this paper, we present an approach to estimate 3D hand pose and object pose in real-time using a low-cost consumer RGB-D camera for human-robot interaction scenarios. We propose a cascade of networks strategy to regress 2D and 3D pose features. The first network detects the objects and hands in images. The second network is an end-to-end model with independent weights to regress 2D keypoints of hands joints and object corners, followed by a 3D wrist centric hand and object pose regression using a novel residual graph regression network and finally a perspective-n-point approach to solve 6D pose of detected objects in hand. To train and evaluate our model, we also propose a small-scale 3D hand pose dataset with a new semi-automated annotation approach using a robot arm and demonstrate the generalizability of our model on the state-of-the-art benchmarks.

@conference{visapp22, author={Chaitanya Bandi. and Hannes Kisner. and Urike Thomas.}, title={3D Hand and Object Pose Estimation for Real-time Human-robot Interaction}, booktitle={Proceedings of the 17th International Joint Conference on Computer Vision, Imaging and Computer Graphics Theory and Applications - Volume 4: VISAPP,}, year={2022}, pages={770-780}, publisher={SciTePress}, organization={INSTICC}, doi={10.5220/0010902400003124}, isbn={978-989-758-555-5}, issn={2184-4321}, }

H. Kisner, Y. Ding, U. Thomas

Chapter 4 - Capacitive Material Detection for Robotic

Grasping Applications

Booktitle: Tactile Sensing, Skill Learning and Robotic Dexterous Manipulation, 2022

DOI: 10.1016/B978-0-32-390445-2.00011-8

Objects with different materials are difficult to distinguish by vision and tactile alone when they are similarly shaped and colored. This is especially important in robotic grasping scenarios, where the grasping task can benefit from incorporating material properties and the ability of their detection in a contactless and, therefore, non-destructive way. The robot can adapt its grasping behavior according to the perceived specific material surfaces. We have demonstrated the use of machine learning on impedance spectra generated from capacitive proximity sensors for material detection. This book chapter provides an introduction to this topic and serves as a guideline for implementation. We also want to provide a more profound investigation into how this approach can be extended with adjustments in the classification pipeline to provide more nuanced and more detailed classifications (e.g., differentiate between different types of woods and metals). We discuss the possibilities and limitations of our approach for grasping.

@incollection{Kisner2022, title = {Capacitive material detection with machine learning for robotic grasping applications}, editor = {Qiang Li and Shan Luo and Zhaopeng Chen and Chenguang Yang and Jianwei Zhang}, booktitle = {Tactile Sensing, Skill Learning, and Robotic Dexterous Manipulation}, publisher = {Academic Press}, pages = {59-79}, year = {2022}, isbn = {978-0-323-90445-2}, doi = {https://doi.org/10.1016/B978-0-32-390445-2.00011-8}, url = {https://www.sciencedirect.com/science/article/pii/B9780323904452000118}, author = {Hannes Kisner and Yitao Ding and Ulrike Thomas}, keywords = {material classification, machine learning, grasp perception, capacitive sensors}, abstract = {Objects that are made of different materials are difficult to distinguish by vision and sensing alone when they are similarly shaped and colored. This is especially important in robotic grasping scenarios, where the grasping task can benefit from incorporating material properties and the ability of their detection in a contactless and, therefore, nondestructive way. The robot can adapt its grasping behavior according to the perceived specific material surfaces. We have demonstrated the use of machine learning on impedance spectra generated from capacitive proximity sensors for material detection. This book chapter provides an introduction to this topic and serves as a guideline for implementation. We also want to provide a more profound investigation into how this approach can be extended with adjustments in the classification pipeline to provide more nuanced and more detailed classifications (e.g., differentiate between different types of woods and metals). We discuss the possibilities and limitations of our approach for grasping.} }

C. Gäbert, S. Kaden, U. Thomas

Generation of Human-like Arm Motions using Sampling-based Motion Planning

Published in IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 2021

DOI: 10.1109/IROS51168.2021.9636068

Natural and human-like arm motions are promising features to facilitate social understanding of humanoid robots. To this end, we integrate biophysical characteristics of human arm-motions into sampling-based motion planning. We show the generality of our method by evaluating it with multiple manipulators. Our first contribution is to introduce a set of cost functions to optimize for human-like arm postures during collision-free motion planning. In a subsequent step, an optimization phase is used to improve the human-likeness of the initial path. Additionally, we present an interpolation approach for generating obstacle-aware and multi-modal velocity profiles. We thus generate collision-free and human-like motions in narrow passages while allowing for natural acceleration in free space.

@INPROCEEDINGS{9636068, author={Gäbert, Carl and Kaden, Sascha and Thomas, Ulrike}, booktitle={2021 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS)}, title={Generation of Human-like Arm Motions using Sampling-based Motion Planning}, year={2021}, volume={}, number={}, pages={2534-2541}, doi={10.1109/IROS51168.2021.9636068} }

C. Bandi, U. Thomas

Skeleton-based Action Recognition for Human-Robot Interaction using Self-Attention Mechanism

Published in 16th IEEE International Conference on Automatic Face and Gesture Recognition (FG), 2021

DOI: 10.1109/FG52635.2021.9666948

Motion prediction and action recognition play an influential role in the enhancement of interactions between humans and robots. We aim to predict motions and recognize actions for an interaction-based supermarket assistance scenario. Skeleton-based prediction of human motion and action recognition methods gained a lot of attention with the help of recurrent neural networks, convolutional neural networks, and graph convolutions. For recognition of actions, most of the proposed architectures rely on the predefined structure of the skeleton. In this work, we introduce a new small-scale dataset with actions that are possible in a supermarket interaction scenario. we propose two different self-attention-based models for recognition of actions for learning long-range correlations that do not rely on a predefined skeleton structure. We evaluate the models with extensive experiments containing specific input feature encodings that enhances the motion or trajectory features for accurate prediction and recognition of actions. We validate the effectiveness of the models on the actions in supermarket dataset and a standard benchmark dataset for action recognition known as the NTU RGB+D dataset.

@INPROCEEDINGS{9666948, author={Bandi, Chaitanya and Thomas, Ulrike}, booktitle={2021 16th IEEE International Conference on Automatic Face and Gesture Recognition (FG 2021)}, title={Skeleton-based Action Recognition for Human-Robot Interaction using Self-Attention Mechanism}, year={2021}, volume={}, number={}, pages={1-8}, doi={10.1109/FG52635.2021.9666948} }

K. Kitz, U. Thomas

Neural dynamic assembly sequence planning

Published in IEEE 17th International Conference on Automation Science and Engineering (CASE), 2021

DOI: 10.1109/CASE49439.2021.9551620

The automatic generation of feasible assembly sequences from CAD-data is for several reasons a challenging task. One reason being that with increasing number of parts of an assembly group, the number of possible sequences grows exponentially, making an exhaustive search non-practical. We face this combinatorial problem by using Reinforcement Learning (Deep-Q-Learning) to approximate the cost-function of the assembly with an artificial neural network (ANN) and guide the search for an asymptotically optimal solution of this combinatorial problem. Assembly costs are calculated with a collision-based assembly-by-disassembly approach. The derived method is tested on assemblies of different sizes and types. The presented method provides collision-free assembly sequences very fast, due to its depth-first character and solves small and medium tasks reliably.

@inproceedings{kitz2021neural,

title={Neural dynamic assembly sequence planning},

author={Kitz, Kristof and Thomas, Ulrike},

booktitle={2021 IEEE 17th International Conference on Automation Science and Engineering (CASE)},

pages={2063--2068},

year={2021},

organization={IEEE}

}

S. Kaden, U. Thomas

Optimizing Mobility of Robotic Arms in Collision-free Motion Planning

Published in Journal of Intelligent & Robotic Systems 102.2, 2021

DOI: 10.1007/s10846-021-01407-0

A major task in motion planning is to find paths that have a high ability to react to external influences while ensuring a collision-free operation at any time. This flexibility is even more important in human-robot collaboration since unforeseen events can occur anytime. Such ability can be described as mobility, which is composed of two characteristics. First, the ability to manipulate, and second, the distance to joint limits. This mobility needs to be optimized while generating collision-free motions so that there is always the flexibility of the robot to evade dynamic obstacles in the future execution of generated paths. For this purpose, we present a Rapidly-exploring Random Tree (RRT), which applies additional costs and sampling methods to increase mobility. Additionally, we present two methods for the optimization of a generated path. Our first approach utilizes the built-in capabilities of the RRT*. The second method optimize the path with the stochastic trajectory optimization for motion planning (STOMP) approach with Gaussian Mixture Models. Moreover, we evaluate the algorithms in complex simulation and real environments and demonstrate an enhancement of mobility.

@article{kaden2021optimizing, title={Optimizing Mobility of Robotic Arms in Collision-free Motion Planning}, author={Kaden, Sascha and Thomas, Ulrike}, journal={Journal of Intelligent \& Robotic Systems}, volume={102}, number={2}, pages={1--15}, year={2021}, publisher={Springer} }

S. Ergun, Y. Ding, H. Alagi, C. Schöffmann, B. Ubezio, G. Soti, S. Mühlbacher-Karrer, M. Rathmair, U. Thomas, B. Hein, M. Hofbaur, H. Zangl

A Unified Perception Benchmark for Capacitive Proximity Sensing Towards Safe Human-Robot Collaboration (HRC)

Published in IEEE International Conference on Robotics and Automation (ICRA) , 2021

DOI: 10.1109/ICRA48506.2021.9561224

During the co-presence of human workers and robots, measures are required to avoid injuries from undesired contacts. Capacitive Proximity Sensors (CPSs) offer a cost-effective solution to cover the entire robot manipulator with fast close-range perception for HRC tasks, closing the perception gap between tactile detection and mid-range perception. CPSs do not suffer from occlusion and compared to pure tactile or force sensing, they react earlier and allow increasing the operating speed of Collaborative Robots (Cobots) while still maintaining safety. However, since capacitive coupling to obstacles varies with their distance, shape and material properties, the projection from capacitance to actual distances is a general problem. In this work, we propose an universal benchmark test procedure for fellow researchers to evaluate their CPSs. Considering ISO/TS 15066 for Power and Force Limiting (PFL) as a reference, we derive the requirements for the specified body regions and propose a method for determining the operation speed to comply with PFL based on a pre-defined detection threshold. Finally, the benchmark test procedure is evaluated on three different concepts of CPSs from the contributedresearchers, demonstrating the general applicability.

@INPROCEEDINGS{Ding2021b, author={Ergun, Serkan and Ding, Yitao and Alagi, Hosam and Schöffmann, Christian and Ubezio, Barnaba and Soti, Gergely and Rathmair, Michael and Mühlbacher-Karrer, Stephan and Thomas, Ulrike and Hein, Björn and Hofbaur, Michael and Zangl, Hubert}, booktitle={2021 IEEE International Conference on Robotics and Automation (ICRA)}, title={A Unified Perception Benchmark for Capacitive Proximity Sensing Towards Safe Human-Robot Collaboration (HRC)}, year={2021}, volume={}, number={}, pages={3634-3640}, doi={10.1109/ICRA48506.2021.9561224} }

Y. Ding, U. Thomas

Improving Safety and Accuracy of Impedance Controlled Robot Manipulators with Proximity Perception and Proactive Impact Reactions

Published in IEEE International Conference on Robotics and Automation (ICRA) , 2021

DOI: 10.1109/ICRA48506.2021.9561025

We present a system which improves the safety and accuracy of impedance controlled robotic manipulators with proximity perception. Proximity servoed manipulators, which use proximity sensors attached to the robot's outer shell, have recently demonstrated robust collision avoidance abilities. Nevertheless, unwanted collisions cannot be avoided entirely. As a fallback safety mechanism, robots with joint force/torque sensing rely on impedance controllers for impact attenuation and compliant behavior. However, impedance controllers induce undesired deflections of the robot from its trajectory when it is not in contact. These deviations are more pronounced at soft configurations and when the robot grasps objects of unknown weight distribution, thus a compromise must be made between high positional accuracy and softness (safety). The proximity information allows the robot to react to anticipated impacts proactively for attenuation and damage reduction of unavoidable collisions, while still maintaining high accuracy during regular operation. This is achieved through variations of impedance parameters according to proximity measurements and motions towards safe joint configurations during the pre-impact phase.

@INPROCEEDINGS{Ding2021a, author={Ding, Yitao and Thomas, Ulrike}, booktitle={2021 IEEE International Conference on Robotics and Automation (ICRA)}, title={Improving Safety and Accuracy of Impedance Controlled Robot Manipulators with Proximity Perception and Proactive Impact Reactions}, year={2021}, volume={}, number={}, pages={3816-3821}, doi={10.1109/ICRA48506.2021.9561025} }

Y. Ding, H. Kisner, U. Thomas

Using Machine Learning for Material Detection with Capacitive Proximity Sensors

Published in IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), 2020

DOI: 10.1109/IROS45743.2020.9341016

The ability of detecting materials plays an important role in robotic applications. The robot can incorporate the information from contactless material detection and adapt its behavior in how it grasps an object or how it walks on specific surfaces. In this, paper we apply machine learning on impedance spectra from capacitive proximity sensors for material detection. The unique spectra of certain materials only differ slightly and are subject to noise and scaling effects during each measurement. A best-fit classification approach to pre-recorded data is therefore inaccurate. We perform classification on ten different materials and evaluate different classification algorithms ranging from simple k-NN approaches to artificial neural networks, which are able to extract the material specific information from the impedance spectra.

@INPROCEEDINGS{Ding2020b, author={Y. {Ding} and H. {Kisner} and T. {Kong} and U. {Thomas}}, booktitle={2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS)}, title={Using Machine Learning for Material Detection with Capacitive Proximity Sensors}, year={2020}, volume={}, number={}, pages={10424-10429}, doi={10.1109/IROS45743.2020.9341016} }

J. Bonse , U. Thomas A New Low Cost Three-Finger Gripper with Hybrid Control with Soft Touch Behavior Accepted for the 52nd International Symposium on Robotics (ISR), 2020