Magnetic thin alloy films

Binary alloys MxPt1-x (M = Fe and Co) prepared in form of thin films develop peculiar magnetic properties, such as a strong perpendicular magnetic anisotropy (PMA), making them good candidates for ultra-high density magnetic recording media.Properties of Fe-Pt and Co-Pt alloys

FePt and CoPt alloys with equiatomic composition adopting L10 structure are among the hardest magnetic materials. Indeed, a value of the uniaxial magnetic anisotropy, KU, of 10 MJ/m3 and the value of the saturation magnetization MS of 1.4 T were experimentally reported for FePt alloy films. Similarly, CoPt alloy with equiatomic composition adopts the chemically ordered L10 phase with magnetic anisotropy values within a range of (2 - 4) MJ/m3 (MS ~ 1 T).However, high annealing temperatures of about 800 K are required to transform an fcc disordered alloy into its L10 chemically ordered phase. Therefore, many studies are directed to lower the ordering temperature by growing alloys on appropriate buffer layers, utilizing surfactants to guide the formation of anisotropic local ordering, by deposition of multilayer nanocomposites, or by He-ion beam irradiation.

In this respect, we have shown a substantial reduction in ordering temperature for CoPt3(111) thin films grown on the low energy surface of WSe2(0001).

WSe2(0001): van der Waals surface

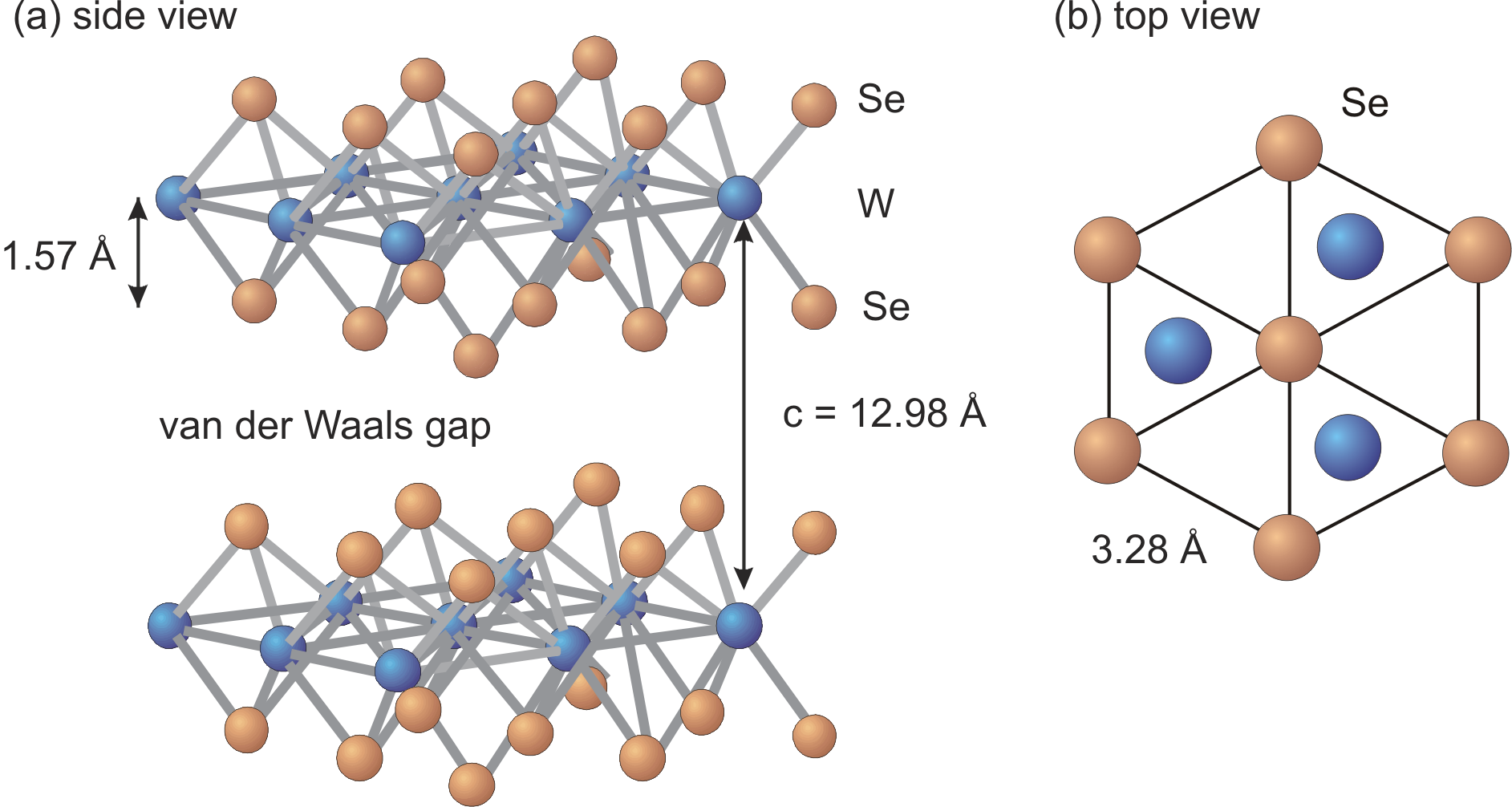

WSe2 is a semiconductor with a layered structure, which belongs to the transition metal dichalcogenides with the structural unit MX2 (M – transition metal, X - chalcogenide) and hexagonal symmetry P63/mmc. The crystal structure of WSe2(0001) consists of a repetition of Se-W-Se trilayers translated along the c-axis (Figure 1). The interaction force between the atoms within the trilayer is a strong covalent force, but neighboring trilayers are connected by weak van der Waals bonds. The layers of chalcogenide atoms (Se), arranged in the lattice with hcp symmetry, sandwich the metal atoms (W). | |

| Fig. 1 Schematic representation of the layered structure of WSe2(0001). |

Due to the presence of the weak van der Waals bonds between Se-W-Se sandwiches, the top WSe2(0001) surface is chemically inert and saturated. This strongly enhances the mobility of adatoms on the van der Waals surface, and thus influences not only the morphology of the deposited films, but also the chemical order parameter of the alloys. Together with the enhanced adatom mobility, this allows the growth of islands of the deposited metals, suitable for further STM and GISAX studies.

FePt alloy films with equiatomic composition grown on WSe2(0001)

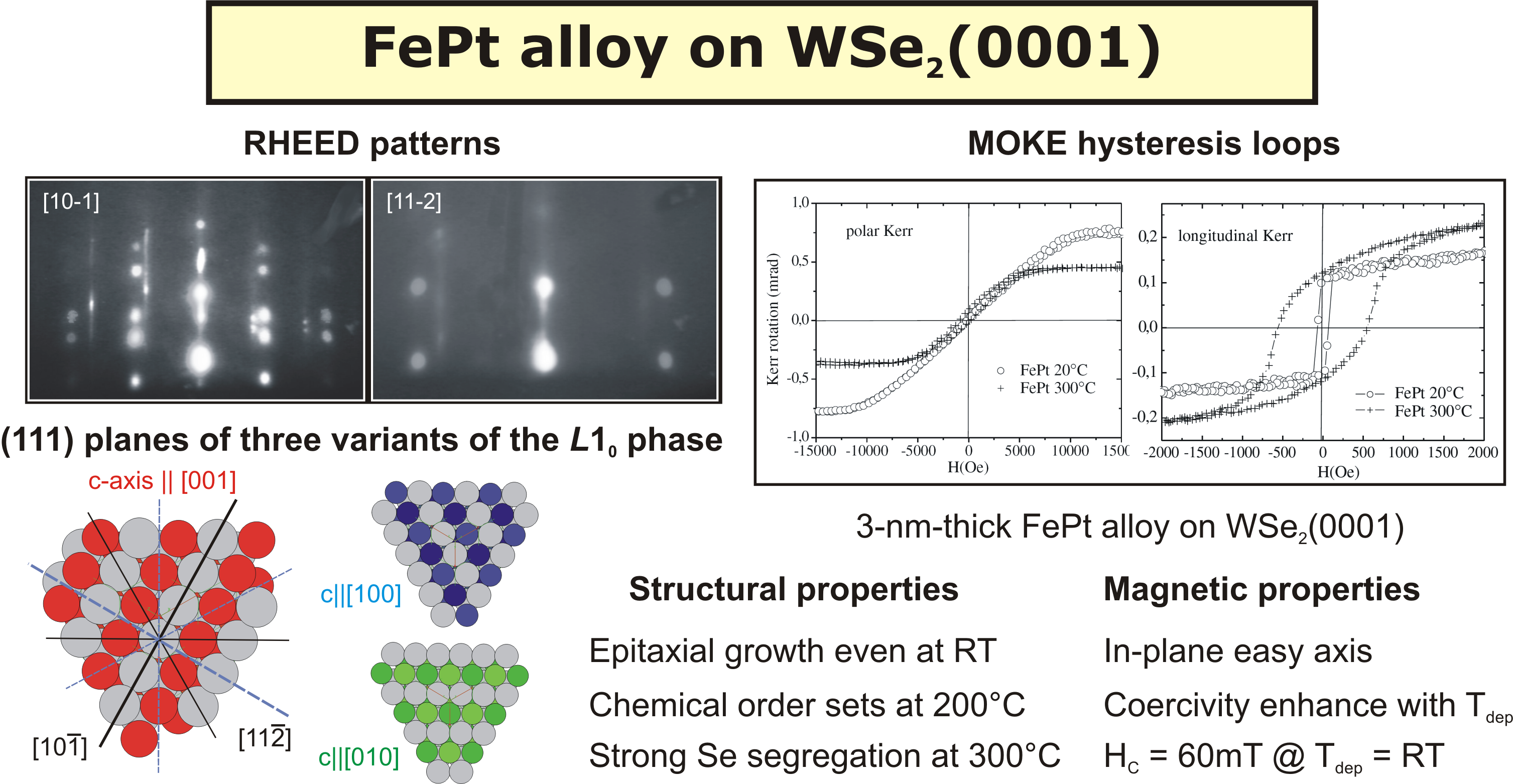

Co-deposition of Fe and Pt atoms on WSe2(0001) in the sub-monolayer range leads to the formation of epitaxial FePt(111) nanostructures with an average lateral size of about 5 nm.Thereby, the formation of the three variants of the L10 phase (Figure 2, left panel) might prevent the increase in size by coalescence of neighboring nanostructures and stabilize {001} facets leading to a more rounded shape of the nanostructures. Moreover, the onset temperature of L10 chemical ordering in thicker films starts already around 200ºC, much lower than reported on other substrate surfaces. However, no PMA was observed in disordered and partly ordered films where the latter is a result of the formation of three variants and the 54º tilting of the tetragonal axis with respect to the growth direction (Figure 2, right panel). Magnetic measurements in 3-nm-thick FePt(111) films have revealed an easy axis of magnetization in the film plane, with a coercivity strongly enhanced with L10 order.

| |

| Fig. 2 (left panel, top) RHEED patterns along the [10-1] and [11-2] azimuths of FePt after a nominal coverage of 0.5 Å FePt on WSe2(0001) at 300ºC. (left panel, bottom) Schematic views of the (111) planes of three variants of the L10 phase formed with the tetragonal axis along (a) [001], (b) [100] and (c) [010] directions of the fcc structure. Alternating pure Fe and pure Pt rows are parallel to the directions [1-10] and [11-2] in each variant leading to the superstructure spots in the RHEED patterns. (right panel) Polar and longitudinal Kerr effect loops measured for 3-nm-thick FePt alloy films grown on WSe2(0001) at room temperature and 300ºC. |

CoPt alloy films with equiatomic composition grown on WSe2(0001)

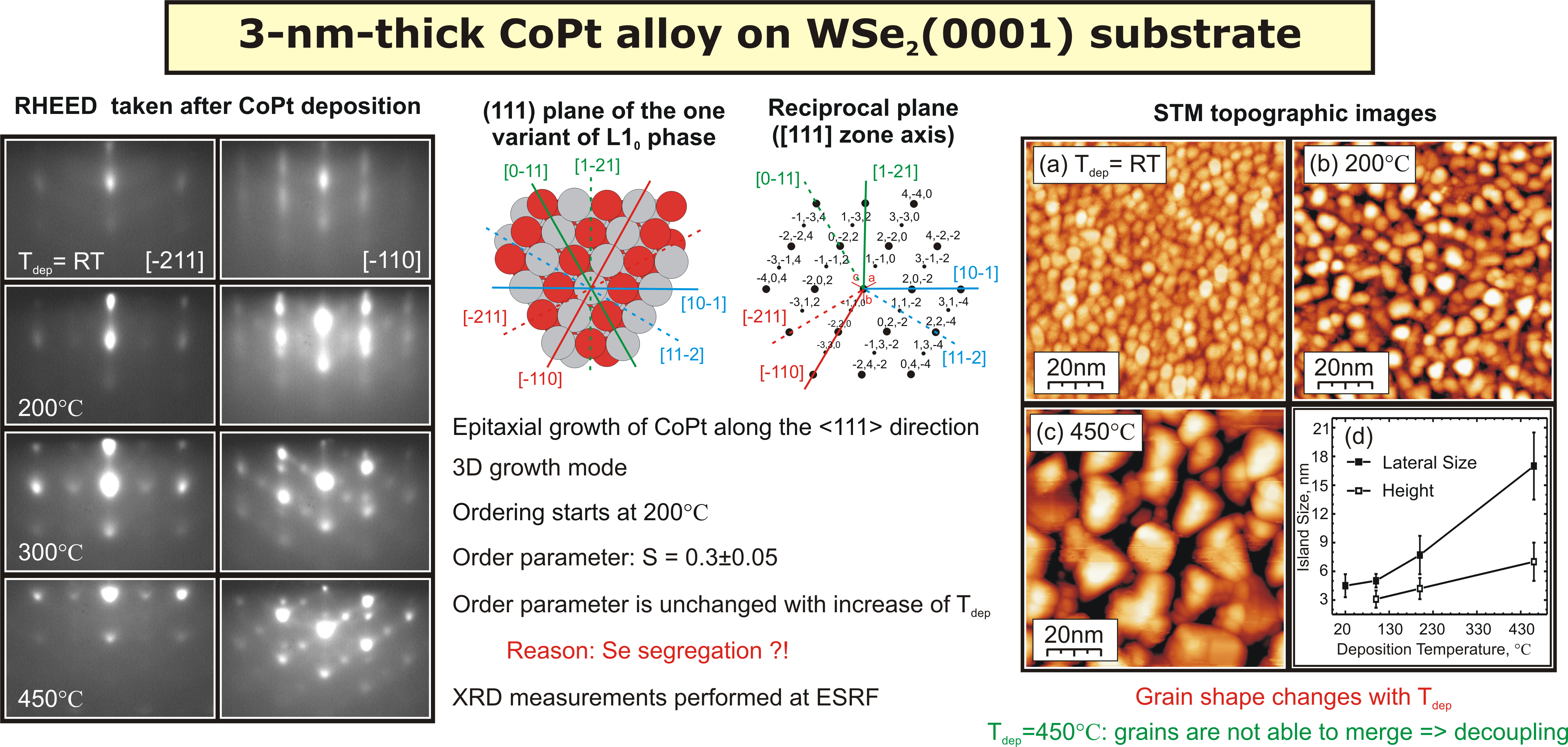

We investigated the structural and magnetic properties of 3-nm-thick CoPt alloy films grown on WSe2(0001) at various temperature. Deposition at room temperature leads to the formation of a chemically disordered fcc CoPt alloy with [111] orientation (Figure 3, left panel). Growth at elevated temperatures induces L10 chemical ordering starting from 470 K accompanied with an increase in grain size and a change in grain morphology. As a consequence of the [111] growth direction, the CoPt grains can adopt one of the three possible variants of the L10 phase with tetragonal c-axis tilted from the normal to the film plane direction at 54° (Figure 3, middle panel). The average long-range order parameter is found to be 0.35(±0.05) and does not change with increasing deposition temperature from 570 to 730 K. This behavior might be related to Se segregation towards the growing facets and surface disorder effects promoted by a high surface-to-volume ratio. | |

| Fig. 3 (left panel) RHEED patterns taken after deposition of a 3-nm-thick CoPt alloy on WSe2(0001) at various temperatures: (a) RT, (b) 200, (c) 300, and (d) 450°C. (middle) Schematic view of the (111) plane of the one variant of the L10 phase, formed with tetragonal axis along [001]; (b) the reciprocal plane corresponding to the [111] zone axis. (right panel) STM topographic images taken after deposition of a 3-nm-thick CoPt alloy on WSe2(0001) at various temperatures: (a) RT, (b) 200, and (c)450°C. STM images are taken at U = 1.0 V and I = 0.1 nA. (d) Grain’s mean lateral size as a function of deposition temperature |