High-Precision Machining in Microcosmic Dimensions

TU Chemnitz’ Professorship Micromanufacturing Technology puts a new high-precision machining center into operation, focused on development and manufacture of functional surfaces

-

Michael Leibnitz (l.) and Prof. Dr. Andreas Schubert discuss a series of tests at the new high-precision machining center. Photo: Pressefoto Schmidt -

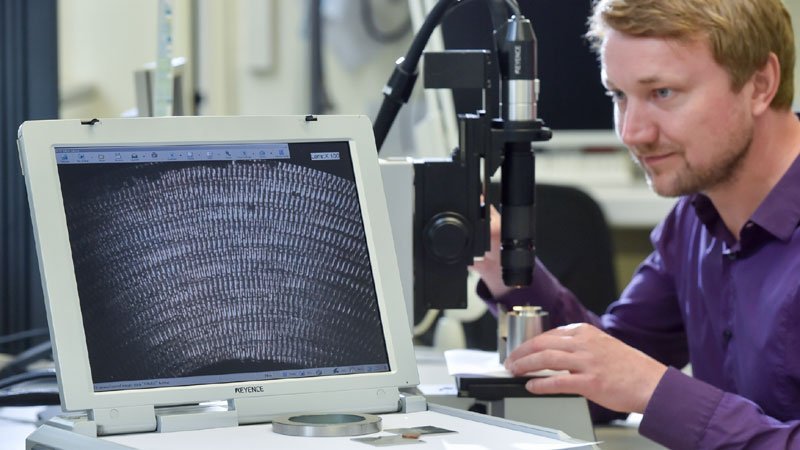

Dr. Henning Zeidler analyzes the surface of a test sample with the help of a video-microscope in the laboratory of the Professorship Micromanufacturing Technology. Photo: Pressefoto Schmidt

Every object is confined by its surface. On the one hand, surfaces must endure great stress – for instance from wind, sun, rain or friction. On the other hand, many surfaces have to fulfill a specific function over a long period of time. Amongst many other areas, there are a lot of such functional surfaces in cars. Among them are brake surfaces, sealing surfaces, joining surfaces, sliding surfaces, rolling surfaces, flow surfaces and many more. Precise utilization of specific characteristics of these surfaces provides a high degree of comfort while driving with low fuel consumption, low emissions and an attractive design. “The potential of functional surfaces is far from exhausted,” states Prof. Dr. Andreas Schubert, Head of the Professorship Micromanufacturing Technology. “Functional surfaces are gaining importance not only in mechanical and automotive engineering, but also in energy production and conversion, in temperature management of technical systems as well as in medical engineering.” One of the professorship’s core competencies is, therefore, the development and manufacture of functional surfaces in order to increase energy and resource efficiency, particularly with innovative lightweight construction materials.

With a high-precision machining center placed in the Institute for Machine Tools and Production Processes, researchers are entering into a new dimension in micromanufacturing. “Thanks to high-precision 5-axis-kinematics, hydrostatic axes and guideways and comprehensive temperature management within the machine, we can produce surface structures with micrometer precision and work accurately on the scale of tiny bacteria,” praises Schubert. A high-precision machining center manufactured by KERN Microtechnik will allow for the application of various different machining technologies, including micro-drilling, high-polish milling and micro-milling as well as grinding in combination with various cooling and lubrication strategies, in order to generate surface characteristics that adequately meet the challenges related to the application field being addressed. The new machine, with a total value of approximately 700,000 euros, was configured especially according to the specifications of the Professorship Micromanufacturing Technology and was financed by the Deutsche Forschungsgemeinschaft as well as the Saxon State Ministry for Higher Education, Research and the Arts using state funds.

A number of scientists and research projects at the TU Chemnitz will benefit from the new technology, including the Collaborative Research Center HALS, in which high-strength aluminum-based lightweight materials are developed, characterized and machined. In addition, students will also profit from the high-precision machining center – particularly in technical degree programs – which can be used during internships or to carry out scientific tasks.

A video of the high-precision machining center in action can be found on the TU Chemnitz’s YouTube Channel (in German).

More information is available from Prof. Dr. Andreas Schubert, Telephone +49 371 531-34580, E-Mail andreas.schubert@mb.tu-chemnitz.de, or from Dr. Andreas Nestler, Telephone +49 371 531-35141, E-Mail andreas.nestler@mb.tu-chemnitz.de.

(Author: Mario Steinebach, Translation: Sarah Wilson)

Mario Steinebach

15.08.2016