Friction and Wear Test Benches

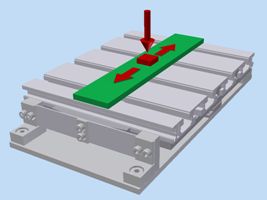

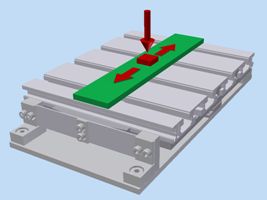

Principle of the Oscillating Friction Measurement

The self-developed friction and wear test stands available on the professorship

of Materials Handling, Conveying and Conveying Engineering work according to the principle of an

oscillating sample movement. A slider-crank mechanism or a linear motor generates this motion. By

applying a defined normal force a moving upper sample is pressed against a lower sample that is

clamped on a spring mounted measuring table. Here the friction between both samples causes a

displacement of the measuring table whereby the deflection is proportional to the friction force.

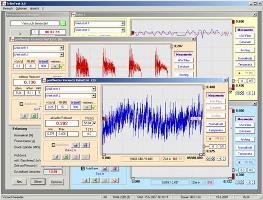

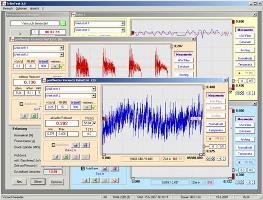

The coefficient of friction obtained can be recorded and evaluated for several weeks by the

specially developed software TriboTest. However the standard test duration is 24 hours.

This functional principle allows the application of linear loads on flat

surfaces as well as a wide range of sample designs. Thus a practical orientation on conveyor

applications can be guaranteed. Square upper samples with dimensions 15 x 10 mm are used as

standard. Lower samples have a length of 150…180 mm. For higher test speed the length can be

increased up to 600 mm. Tests of real components are also possible, e.g. chain link against

profile section.

| 2-Track Tribological Test Bench "TriboOne" |

- Principle of measurement: plate on plate, oscillating

- Measuring points: 2 (velocity identical, sample and force could be different)

- Stroke (oscillating movement): up to 150 mm

- Sliding speed: up to 0,6 m/s

- Normal force: up to 500 N

- Duration of the test: no limitations (standard = 24 hours)

- Climate conditions: 23±5°C, 50±10% relative humidity (RH)

|

|

| 4-Track Tribological Test Bench "TriboBoxer" |

- Principle of measurement: plate on plate, oscillating

- Measuring points: 4 (velocity identical, sample and force could be different)

- Stroke (oscillating movement): up to 150 mm

- Sliding speed: up to 1 m/s

- Normal force:up to 250 N (if necessary up to 200 N)

- Duration of the test: no limitations (standard = 24 hours)

- Climate conditions: 23±5°C, 50±10% relative humidity

|

|

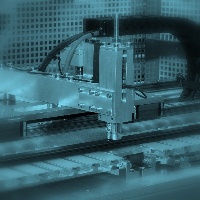

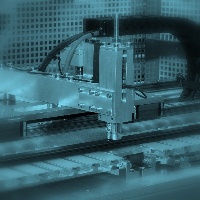

| 4-Track Tribological Test Bench "TriboSPEEDster" |

- Principle of measurement: plate on plate, oscillating

- Measuring points: 4 (velocity identical, sample and force could be different)

- Stroke (oscillating movement):up to 600 mm

- Sliding speed: up to 2 m/s (at 600 mm hub)

- Normal force: up to 400 N

- Duration of the test: no limitations (standard = 24 hours)

- Climate conditions: 23±5°C, 50±10% relative humidity

|

|

| Tribological Testing Device in Climate Chamber |

- Principle of measurement:plate on plate, oscillating

- Measuring points: 2 (velocity identical, sample and force could be different)

- Stroke (oscillating movement):up to 270 mm

- Sliding speed: up to 1 m/s

- Normal force: up to 200 N

- Duration of the test: no limitations (standard = 24 hours)

- Climate conditions: -30…+100°C

- Relative humidity: 10…98%

|

|

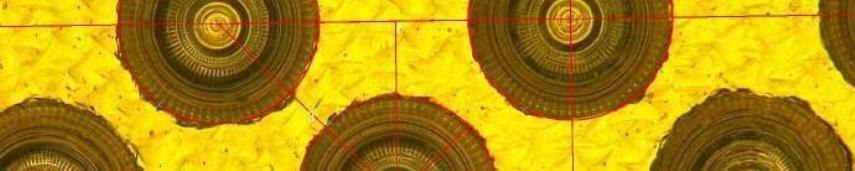

| Linear Tribological Test Device |

- Principle of measurement: plate on plate, linear

- Lenght of measurement: up to 1000 mm

- Sliding speed: up to 0,2 m/s

- Normal force: up to 500 N

- Duration of the test: short time (individual measurement over the length)

- Climate conditions: 23±5°C, 50±10% relative humidity

|

|