Prediction tool for plasma nitriding results

In a joint project between the Fraunhofer Institute for Surface Engineering and Thin Films (IST) and the Chair of WOT at Chemnitz University of Technology (IWW), a forecasting tool for plasma nitriding results has been developed for twelve steel grades to date, which, in addition to a broad database of nitriding results, also offers a software-based prediction trained using an artificial neural network.

The IGF project IGF 18741 BG entitled „Prediction tool for plasma nitriding processes for the surface treatment of tools and components“ of the German Society for Electroplating and Surface Technology was funded by the Federal Ministry for Economic Affairs and Energy via the German Federation of Industrial Research Associations „Otto von Guericke“ e.V. as part of the programme for the promotion of joint industrial research on the basis of a resolution of the German Bundestag.

In plasma nitriding, there are complex relationships between the nitriding parameters (such as treatment duration, process temperature and gas composition), the alloying elements contained in the base material, the component geometry and the nitriding result. The most important parameters for the user to evaluate the nitriding result are the nitriding hardness depth and the hardness gradient in the component edge zone. In the past, there was a lack of reliable knowledge about these correlations, which was mostly due to a lack of systematically recorded data.

As part of the IGF project „ProgPlas - Prediction tool for plasma nitriding processes for the surface layer treatment of tools and components“, more than 500 combinations of twelve different materials with different sets of process parameters were therefore produced and then analysed in relation to the nitriding result. All the data was then presented in the form of user-friendly result maps, which provide a quick overview of materials, nitriding parameters and results. On the other hand, the compiled database was used to create an artificial neural network that identifies the relationships between all process- and material-related input parameters and the nitriding hardness curve. The extensive database also makes it possible to generate nitriding hardness curves from input data that has not been taught in. A graphical user interface was set up to make the trained network user-friendly.

The forecasting tool created will also be expanded in the future with further experimental data and thus become more and more generally applicable. The data available to date is already helping to better utilise the potential of nitriding in practice by allowing the user to access optimal, i.e. effective and efficient process parameters. The optimised approaches can be used, for example, to increase tool life or the service life of components.

Further links:

Online forecasting tool:

https://mala.txm.de/webapps/home/session.html?app=NitridingTool

PDF download of the article:

https://www.tu-chemnitz.de/mb/WOT/forschung/forschungsprojekte/aif_bmbf_sab/IGF18741.pdf

The final report on the project can be requested by e-mail from the following address:

thomas.grund@mb.tu-chemnitz.de

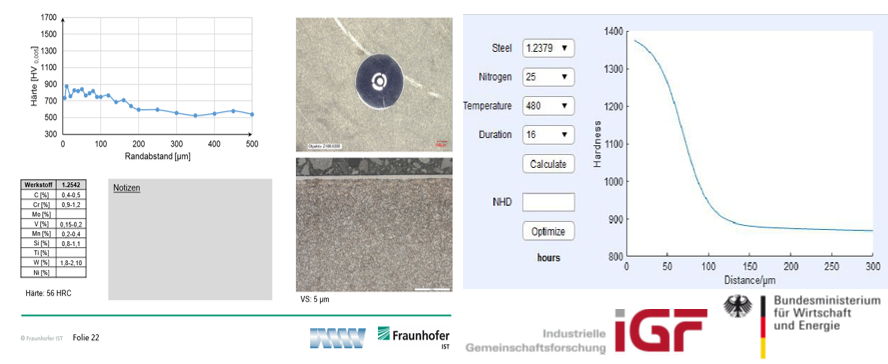

Picture:

Left: Example results map, overview of material, nitriding parameters and result; right: user interface of the prediction tool based on an artificial neural network

27.1.2020 – Projects of the professorship ( thomas.grund@mb… )