Projects

Research Topics

According to the bridging function of the recently established chair for Chemical Technology at TU Chemnitz the research topics have a focus on materials syntheses and characterisations with combinatorial and high-throughput methods as core themes.

Traditional material development is characterized by a "one-after-the-other" principle, which is low and ineffective. But the parameter spaces for the search for new materials are extremely huge; especially in chemistry the main variation parameter is chemical composition of com-pounds consisting of chemical elements from a pool of about 70 practically usable ones of the periodic system of elements (PSE). Even the combination of for example 4 chemical elements in a HT superconductor as YBa2Cu3O7-δ from the 70 utilizable ones results in

combinations and that even without variation of the element fractions!

Already J. J. Hanack has stated in a paper in the year 1970:

"…the present approach to the search for new materials suffers from a chronic ailment, that of handling one sample at a time in the processes of synthesis, analysis and testing of properties. It is an expensive and time consuming approach, which prevents highly-trained personnel from taking full advantage of its talents and keeps the tempo of discovery of new materials at a low level."

By using High-Throughput Technologies this search can be organised essentially more effective. A modern high-throughput experimental cycle stipulates the following sub-steps:

source: R. Potyrailo, K. Rajan, K. Stöwe, I. Takeuchi, B. Chisholm, H. Lam, ACS Combi. Sci. 13 (2011) 579

It will be passed through iteratively until a certain predefined development objective has been reached. With each iteration the number of investigated samples (hits) is reduced. But the information depth of measurement data for the samples is increased from cycle to cycle. At the end of the process one gets a few new materials or only one optimised lead, which will be scaled up later on.

In the past we used this procedure successfully for development and optimisation of new heterogeneous catalysts for numerous processes, e. g. for Diesel exhaust particulate (soot) catalysis, selective catalytic reduction of nitrogen oxides with ammonia (NH3-SCR), ), reduction of methane-slip in biogas engines, improvement in chlorine production efficiency, testing of electrocatalysts for fuel cell application or chalcogenide nano-particle syntheses.

Moreover in cooperation with regional and national companies the chair is proceeding in current projects for optimisation of industrial production processes of chemical products, as for example synthesis of vinyl acetate monomers (VAM) in microstructure reactors or feedstock recycling of polyolefin re-granulate by thermolysis (FAKT), as well as in acquiring similar new topics.

Research Topics of the Past

1. Preface

The chair holder's research topics in the past were preferentially focused on different fields of inorganic solid state chemistry. One centre of interest was laying in preparation and characterisation of binary and ternary compositions of 6th main group elements with f-elements like rare earths or actinide metals M, in which homonuclear contacts Q-Q and/or M-M occur.

By looking for new challenges in direction of "industrial chemistry" in July, 2004, focal points in the field of heterogeneous catalysis increasingly were foregrounded.

2. Inorganic solid state Chemistry

A. Structural investigations on polychalcogenides

The scope of research was the development of a systematic classification of solids according to stability fields for certain structural elements based on x-ray diffraction analysis, supported by spectroscopic investigations as well as theoretical calculations. Some examples of examined compositions are Er2SeSiO4 [5], NaErSe2 [15], ErSeBr, ErSeI [15], Er2Te3 [21], Er0.85Te [20], Er2.15Te3I [20], Th7Te12, US3, UFe8S17 [14], UTe2 [9], U2Te5 [8], UTe3 [7], U0.9Te3 [13], ZrTe3 [19], TlTe [25][29][36], LaTe2 [31], CeTe2 [32], PrTe2 [33], NdTe2-x [37], SmTe2-x, K2UTe3 [26][27], numerous compositions of formula category ALnTe4 [46][47], ALnTe2, ALn3Te8 (A = K, Rb, Cs and Ln = rare earth metal), alkali metal tellurides Rb2Te [45], K2Te, interalkali metal tellurides MM´Te such as CsNaTe (+ 8 additional compositions) etc.

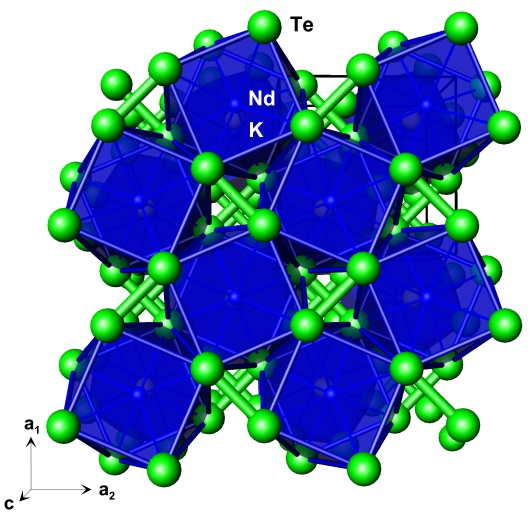

Crystal structure of KNdTe4

B. Material science aspects

Polychalcogenides are particularly interesting because of their technical importance. For instance polychalcogenide glasses are important materials for non-linear optics, IR light-guides, optical switches, optical switching elements etc. According to the amorphous nature of these compounds the structure-property relationships can only be identified with enormous difficulties. Well characterised crystalline polychalcogenides may serve as model substances to ex-plore the structure-property relationships.

C. Study of physical properties

A matter of particular concern was to characterize the prepared compositions with different x-ray diffraction and spectroscopic methods according to their physical properties, in order to end up in a deeper knowledge on homo nucleus contacts. Within x-ray diffraction characteri-sation a broad range of different methods was used, varying from powder methods at high and low temperatures, high pressures in diamond anvil cells DAC, to single crystal x-ray dif-fraction, up to the characterization of of thin films using grazing incidence x-ray diffractometry GID, grazing incidence x-ray reflectometry (GDXR) or total reflection x-ray fluorescence (TXRF). For measurements under grazing incidence a specifically small UHV chamber with a Be cupola and high voltage electron impact heating for a Seifert MZ6 4-cycle diffractometer was developed and constructed. Concerning spectroscopic methods UV- and IR spectrometer were used for optical band edge determination in semiconductors (cooperation with BASF - pigment research) as well as scanning probe technologies (AFM and STM). Furthermore NMR spectrometer were applied for CPMAS-NMR measurements. Also an intensive long standing cooperation with the institute of experimental physics aroused that facilitated photoelectron (Prof. Dr. S. Hüfner) and Raman spectroscopic (Prof. Dr. H.-G. Unruh) measurements. For a long period of time photoelectron spectrometers of Prof. Hüfner's working group (VG MProbe and VG Escalab MKII) had been kept running and in good conditions by our coworkers. Further cooperations were generated by involvement in special research field SFB 277. Also of great avail were contacts to Max Planck institute for solid state research in Stuttgart, Germany, to perform conductivity measurements, magnetic measurements etc. Especially for the characterisation of polytelluride compounds the possibility of performing 125Te-Mößbauer-spectroskopic investigations (Prof. Dr. G. Langouche, Katholieke Universiteit Leuven, Belgien) and XANES-measurements (Prof. Dr. J. Hormes, Bonn) were very use-ful. For the determination of magnetic structures contacts were established major research facilities offering the possibility of neutron diffraction measurements (Institut Laue-Langevin ILL, Grenoble, France and Forschungszentrum FZ Jülich, Germany)

D. Theoretical calculations

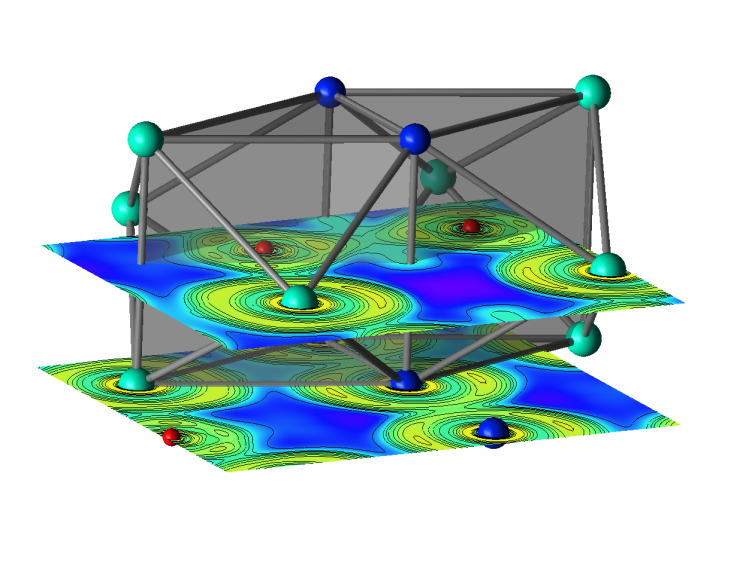

ELF sectional views in coordination polyhedra of UTe2

Electronic band structure calculations have been carried out on ab-initio level, e.g. using Density Functional Theory DFT in the local density approximation (LDA) within the framework of the scalar relativistic Linear Muffin-Tin Orbital method (LMTO) implemented in the software package of Andersen et al. (MPI Stuttgart, Germany) or using the Full Potential Linearized Augmented Plane Wave (FP-LAPW) package (WIEN) of Blaha et al. (University Wien, Austria) for the calculation of crystal properties. For the discussion of chemical bonding also e.g. the Electron Localisation Function ELF has been calculated and characterized according to its topology. The plane-wave pseudo-potential program CASTEP (calculation of state function) has proved a valuable tool for supplementing high pressure investigation results in diamond anvil cells by optimizing geometry parameters and calculating total energies.

E. Study of reaction kinetics

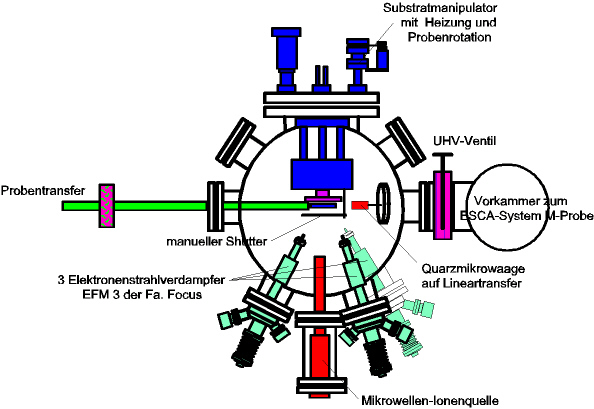

A further matter of particular concern was the reaction kinetic study of solid state chemical reactions with in-situ methods. For this an application for a third party funding in the DFG-SPP "Reactivity of Solids" has been filed to acquire a UHV-MBE deposition system, because this objective could only be realized by application of thin layers (in Å scale) as reactant under ultra-high vacuum conditions. By the elimination of long diffusion pathways limiting reaction rates at low temperatures also kinetic instead of only thermodynamic controlled reaction products can be formed. By this way also new metastable compositions should be accessible, whose formation can be observed by in-situ methods like photo electron spectroscopy or X-ray diffraction.

UHV deposition system

3. Activities in the field of Industrial Chemistry

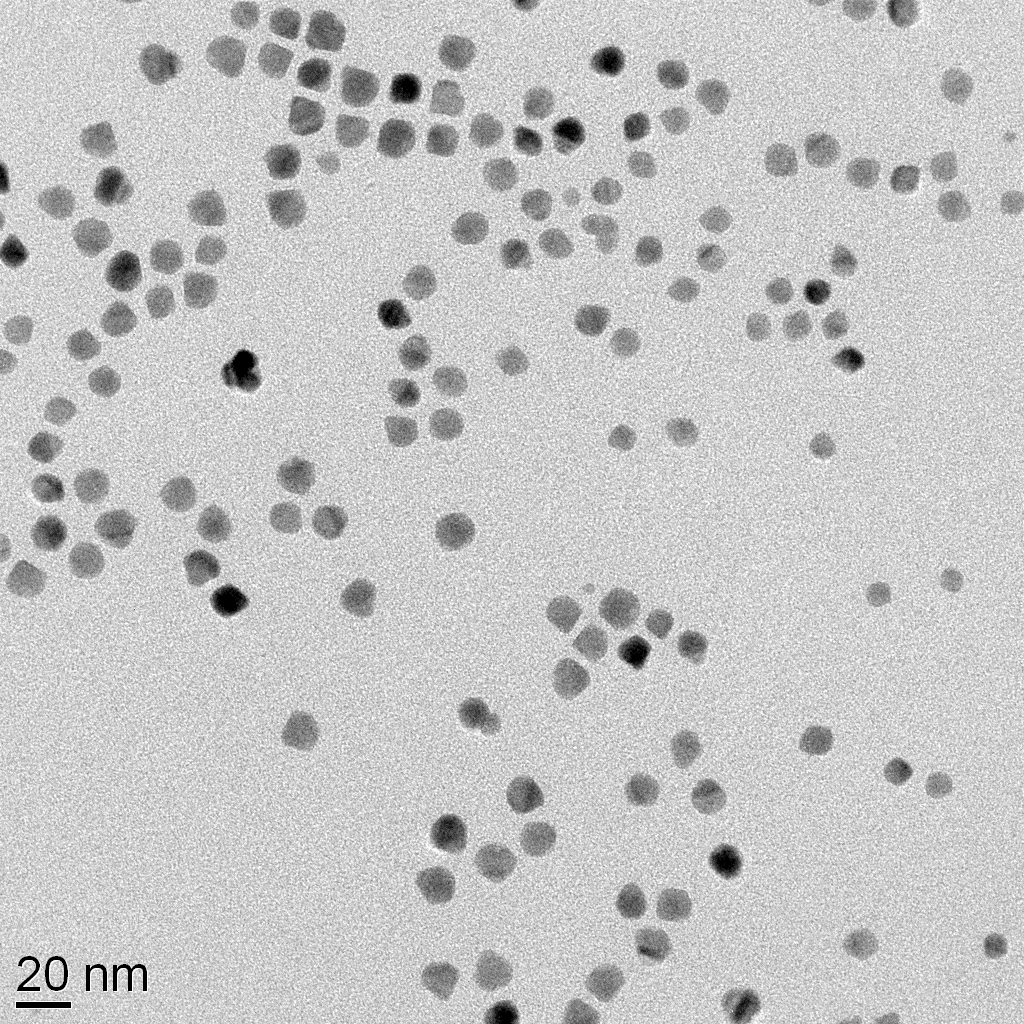

Since July, 2004, the main focus of research was directed to the field of industrial chemistry, especially to the field of heterogeneous catalysis and here particularly to Combinatorial Chemistry CC under the commitment of High-Throughput Technologies HTT. Specialty is the screening of catalyst libraries using emission corrected IR-thermography ecIRT. Projects are engaged e.g. in catalysts for CO oxidation in respiratory protection systems, in sensor systems for combustion gases or for fuel cell applications and in exhaust gas catalysis in automotive systems like the Diesel particulate filter DPF. Industrial cooperations e.g. with companies like VW, Eberspächer and Degussa were possible due to the project management in a BMBF funded project, called "Catalytically active nanomaterials for surfaces in combustion engines and in the exhaust gas system: NanoKat". Objective of a DFG funded project was the targeted synthesis of nanoscaled, narrow banded chalcogenides as catalysts and materials e.g. for photo catalysis. In a further project we were going into the mechanisms of the formation of chalcogenide and polychalcogenide nanoparticles at high temperature synthesis in high-boiling solvents like trioctylphosphine (TOP). Here we also developed parallel reactor systems for automated nanoparticle synthesis, in order to eliminate disturbing influences in the consequence of manual handling, which may have a negative effect on the particle size distribution. They can be exerted e.g. in thin film or hybrid-solar cell applications.

TEM micrograph of CdS nanoparticles by HT synthesis

In two cooperation projects with Umicore AG precious metal-free catalysts were searched elimination of CO elimination from hydrogen containing feed gases for fuel cells as well as for electrode catalysts in fuel cell applications. In May 2009, the BMBF project "Improvement in efficiency at the chlorine synthesis" accrued. Focus of the project was the combinatorial research for new, stable and active catalysts for the transformation of brine or hydrogen chloride in chlorine. The project was divided in two subprojects, in the electrolytic decomposition of chloride containing solutions via electronically conductive oxide catalysts and in the Deacon process i.e. the gas phase transformation of hydrogen chloride with oxygen to chlorine and water.

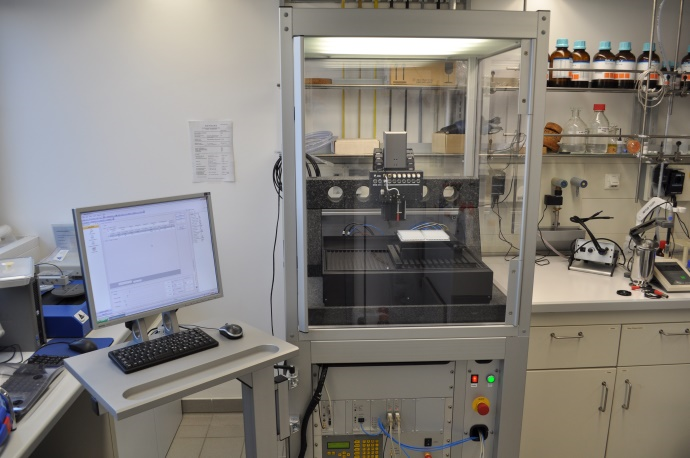

Lab-Inkjet-Printing-System Autodrop

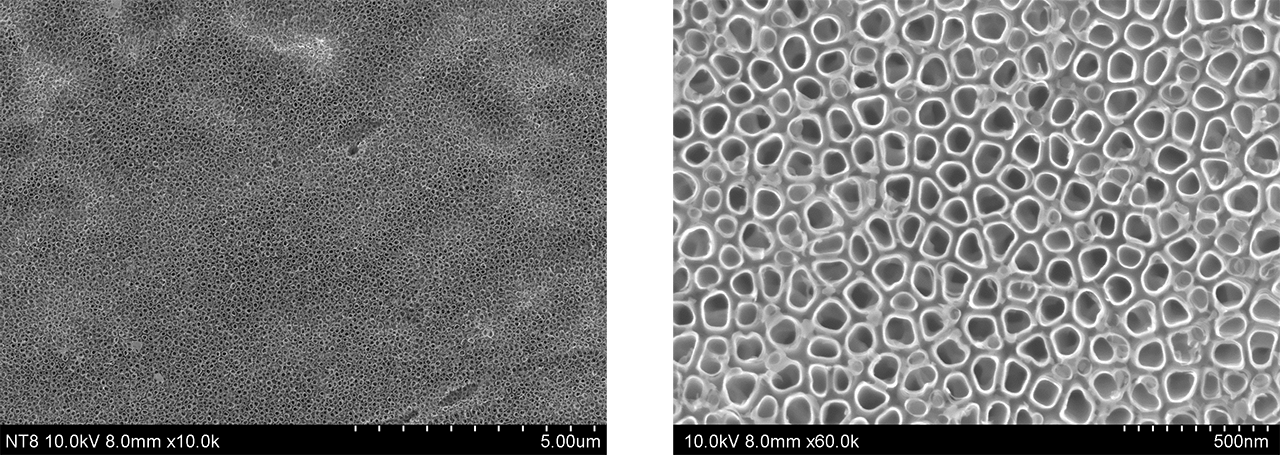

In the last years the field of research also focused on inkjet printing technologies (Autodrop system; Microdrop Corp.). This technique offers numerous advantages for High-Throughput Synthesis HTS of catalyst libraries: high flexibility, e.g. in the chemical composition of solutions, high reproducibility in droplet formation etc., so that this method is suited perfectly well to create composition spread libraries. In those libraries the sample density is very high (a typical droplet diameter is in the range of 30 - 70 µm or 20 - 150 pl volume), that means a coverslip sized area contains several thousands of different compositions, which could be tested simultaneously according to their properties. In the field of catalysis successful testing is performed e.g. by IR thermography with macro lenses; other screening techniques are contemplated. For IR thermography the used substrates have to be porous, so that a sufficient high conversion and therefore a sufficient high reaction heat can be achieved. For this purpose we used TiO2 nanotubes prepared by anodic oxidation on titanium foil, which were offering the possibility to impregnate different materials into the pores.

TiO2 nanotubes by anodic oxidation

A number of projects in cooperation with industrial partners have been elaborated or are still under elaboration: e.g. topics as catalytic methane oxidation in biogas engine exhausts (Heraeus Deutschland GmbH & Co KG), catalytic Diesel soot combustion (Treibacher Industrie AG) as well as development of electrocatalyst and support materials for PEMFC (Umicore AG).

Further topics which are currently worked on in graduate thesis, diploma thesis or civil service examinations, are the catalytic nitrogen elimination in exhaust emissions (NH3-SCR), synthesis and characterisation of nanoscaled, interface modified chalcogenides (e.g. for solar cell application), as well as the search for new thermochemical storage materials.

Cooperations with partners from industry, e.g.

- BMBF "DelLead" project: lead-free piezo ceramics for actuator engineering; Partner: Siemens AG, Bosch GmbH, FhG/IKTS Dresden, Argillon GmbH, University Karlsruhe, University Hamburg, FKZ03X4002E

- DBU project: development of a catalytic post-combustion for a process-integrated ex-haust gas cleaning via electrically regenerated activated carbon fibre fabric. Partner: upt GmbH, NANO-X GmbH

- BMWA project: energy savings through adsorption on electrically regenerated active carbon fibre fabric with integrated catalytic oxidation of desorbed and enriched hazardous substances: upt GmbH, NANO-X GmbH, FKZ 0327338A

- Project: CO methanisation catalysts for fuel cells, Partner: Umicore AG

- Project: combinatorial development and characterisation of electrocatalysts for fuel cells; Partner: Umicore AG, UdS (in cooperation with Prof. Dr. R. Hempelmann, UdS)

- Project: soot combustion catalysts for automotive applications, Partner: Bosch GmbH

- Project: exhaust gas catalysts for small combustions engines, Partner: Heraeus GmbH

- Project: precious metal-free electrocatalysts for the direct methanol fuel cell DMFC, Partner: Umicore AG

- BMBF "NanoKat" project: catalytically active nanomaterials for surfaces in combustion engines and in the exhaust gas system; Partner: Volkswagen AG, Evonik-Degussa AG, Eberspächer AG, Fh-IFAM Bremen, Fh-IST Braunschweig, PCI Heidelberg, FKZ 19U5028G

- Project: optimisation of catalytically active nanomaterials in the exhaust gas system of Diesel fuelled engines, Partner: Volkswagen AG

- Project: halide-resistent exhaust gas catalysts; Partner: Heraeus GmbH

- Project: electrocatalysts for chlorine-alkali electrolysis; Partner: Bayer AG, UdS (in cooperation with Prof. Dr. R. Hempelmann, UdS)

- BMBF project: efficiency increase in chlorine production; Partner: Bayer AG, Nano-X GmbH, FAU, JLU, RUB, TUB, UdS (together with Prof. Dr. R. Hempelmann, UdS) FKZ 033R018G

- Project: development of new catalytic materials for Diesel soot combustion via High-Throughput Technologies; Partner: Treibacher Industrie AG

- Project: new catalytic materials for methane slip reduction from biogas fuelled combustion engines, Partner: Heraeus Deutschland GmbH & Co KG

- DBU project : scientic supervision of a new process for waste water treatment by ceramic membrane filters and ozone ventilation studied for the seal basin at the communal zoo of Saarbrücken city, KOAS, audita UB GmbH, Junghans, AZ 27540/02

- BMWi "NeoKaR II" project: "new highly efficient catalysts for fuel cell applications of the future - from model systems to real catalysts - part II" high-throughput discovery and development of new cathode catalysts for the oxygen reduction reaction ORR in PEMFC"; Partner: Umicore AG, FKZ 03ET2035

- Project: catalytic plastics pyrolysis; Partner: Outotec GmbH Oberursel