Completed Research Projects

Project homepage: CattleHub

Quantification of the finishing process mechanical blasting for process chain automation

“QuaSt” is a joint research project within the "Zentrales Innovationsprogramm Mittelstand (ZIM)", translating to “Central Innovation Programme for small and medium sized enterprises”, which is being worked on in close cooperation between Chemnitz University of Technology professorships and industrial companies. The consortium consists of professorship Production Systems and Processes, professorship Production Measurement Technology, professorship of Management Accounting and Control as well as of industry partners BMF GmbH and H+E Produktentwicklung GmbH.

The project aims at the development of an automated, efficient and integrated finishing process using mechanical blasting. The identification of process-relevant and quality-influencing parameters will provide the basis for resulting quantification and automation of the process chain, which will enable the reproducibility of defined surface properties. Consequently, improvements in quality and lower costs can be achieved for the broad mass of users. Significant added value can be seen in the savings in scrap and post-processing costs as well as in the reduction of processing time; the process stages of preprocessing and final processing should be set and controlled in a targeted manner.

Within the project, the professorship of Management Accounting and Control is especially in charge of developing a concept for the economic appraisal and control of quality costs for the process chain of final processing by means of mechanical blasting. This task comprises the following key activities:

- Identification of process parameters with a high influence on the quality-related costs within the scope of the analysis of the blasting process.

- Determination, planning, forecast and control of the quality-related costs of the investigated process chain.

- Development and application of a quality cost calculation, which brings the process parameters of the preprocessing and finishing in relation to the desired surface quality.

- Development of methods and instruments that set the quality of the components and the necessary resources (including measurement technology) in relation to the costs as well as facilitate the derivation and implementation of measures to influence the costs of the entire blasting process or individual sub-processes.

- Design of interfaces between quality cost control and systems of production quality control as well as other (sub) systems of corporate accounting.

Project homepage: QKiPPP

Project homepage: ecoWing

Project homepage: NeMaCell

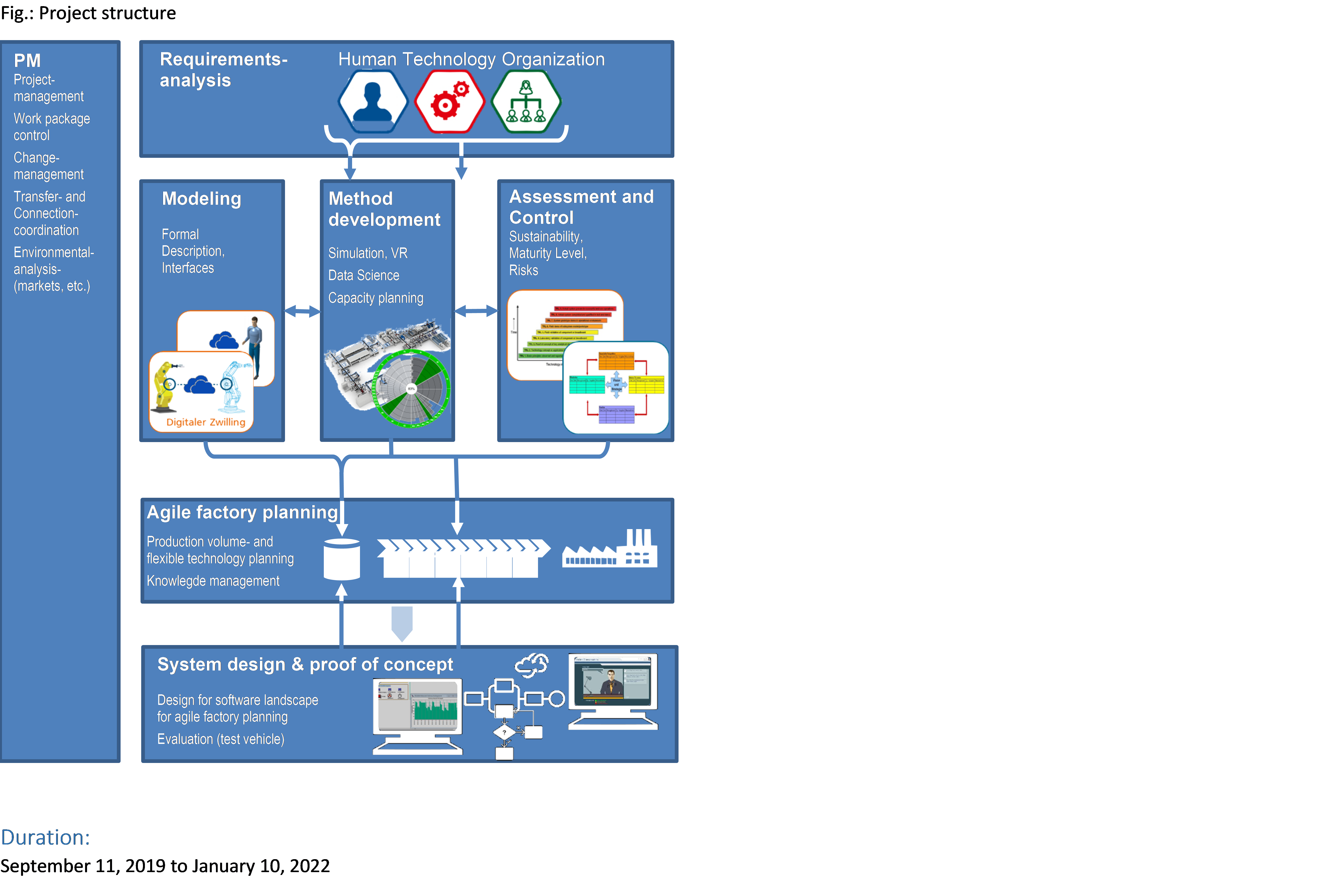

Agile factory planning in the highly dynamic market and development environment of fuel cell production

In the project, agile project management methods are to be used to develop a proactive factory planning procedure that enables short-cycle planning of production systems and processes with high volatility and uncertainty in the input conditions and which can be scaled to a large extent.

As with any other planning and management task, there are economic, social and ecological sustainability aspects to be address during factory planning as well. Therefor the tasks of the chair of Management Accounting and Control within the scope of this project is to deliver instruments for assessing and managing sustainability aspects of different alternatives for fuel cell production systems. As a result of the early phase of the market and the underlying technology, corresponding assessment/management tools must be able to deal with uncertainty as well as risks.

Objectives:

- Development of a system for digital modeling and system design in agile processes, based on the approach of the digital twin

- Development of a planning-integrated evaluation method for maturity, risk, flexibility, sustainability and versatility of production systems

- Design of a software prototype to support agile factory planning processes

Funding and project management

ESF-EFRE Technologieförderung, SAB Sächsische Aufbaubank

Partner:

Fuel Cell Powertrain GmbH, Fraunhofer-Institut für Werkzeugmaschinen und Umformtechnik, Hörmann Rawema Engineering & Consulting GmbH, SimPlan AG, Technische Universität Chemnitz

Diese Maßnahme wird mitfinanziert durch Steuermittel auf Grundlage des von den Abgeordneten des Sächsischen Landtags beschlossenen Haushaltes.

Grüne Energie in industriellen Verbünden

In cooperation with Fraunhofer Institute for Machine Tools and Forming Technology (IWU), the city of Limbach-Oberfrohna and eins energie sachsen GmbH & Co. KG, the professorship of Management Accounting and Control is investigatiung the possible proactive cooperation of operators, energy providers and domiciliary companies in industrial/commercial parks. This project is called ‘Grüne Energie in industriellen Verbünden - GRIDS’. As a result changes in energy market such as rising energy prices or uncertainties of supply can be successfully overcome.

The aim of the project is the development and evaluation of business models, design and planning methods as well as algorithms for synchronized operation of energy sources, energy storage and energy sink. In the future, industrial/commercial parks should be planned and operated more efficiently than today in terms of energy, economy, ecology and quality of supply.

The tasks of the professorship of Management Accounting and Control are within the scope of this project in the following: areas:

- Development of new business segments and models in relation to ancillary services and energy market trading for providers, network operators and users

- Development and application of a model for assessing the economic efficiency (Life Cycle Costing) and environmental sustainability (for example by generating CO2 equivalents) of a supply concept for industrial/commercial park users including the supply media of electricity, heating and cooling with their generation, storage and use, taking into account quality of supply as a constraint

- Systematic recording of user requirements for a supply concept and integration of the same into a target costing approach for user-adequate control of the design of individual elements of the supply concept from an economic point of view (Target Costing)

- Development of cooperation models for infrastructure operators, media suppliers and end customers

- Creation of a planning guide for "brownfield" projects (revitalization of an industrial park) and for "greenfield" applications (designing of an industrial park)

In cooperation with DB RegioNetz Verkehrs GmbH, a transfer assistant is employed at the Chair of Management Accounting and Controlling to support innovation and value creation activities in the field of "Alternative Drives and Digitalisation in Railway Transport" at the interface between Chemnitz University of Technology and the regional railway/mobility sector. The Erzgebirgsbahn and the Fahrzeug- und Technologiezentrum Chemnitz (FTC), which operate as profit centers within DB RegioNetz, and other regional partners are to be put in a better position to open up new markets with innovative products and services by transferring research results into business. For this purpose, the services offered by Chemnitz University of Technology, especially in the areas of integrated technology and business model development as well as technology, innovation and supply chain management, are to be mobilised, developed further for rail transport on specific topics and made known to companies. The transfer assistant will contribute with own technical-economic concepts and analyses to the commercial utilisation of railway innovations and help to build up and expand regional cooperation and network relations by bringing together matching needs and service offers and establishing contacts between innovation partners. In this way, the Chemnitz-Erzgebirge region is to be developed into a competence and technology centre for future railway technologies.

Funded by:

Technological and economic assessment of the application of active flow control to Optimize the wind harvesting capacity of Wind power plants

'TOpWind' is a joint research project within the 6th energy research project "Forschung für eine umweltschonende, zuverlässige und bezahlbare Energieversorgung" which is being worked on in close cooperation between research institutions, university professorships, industrial companies and SMEs. Besides Chemnitz University of Technology, the consortium consists of Siemens Gamesa Renewable Energy SA, ALTRAN Deutschland SAS & Co. KG, INVENT GmbH, IBK Innovation GmbH & Co. KG, various institutes of the Fraunhofer-Gesellschaft für angewandte Forschung e.V. and Deutsches Zentrum für Luft- und Raumfahrt e.V.

The project aims at the development of concepts and technologies for optimizing the efficiency, reliability and profitability of wind turbines. In particular, the focus is on developing technical solutions to increase the efficiency of wind turbines and to minimize structural loads. This is to be achieved by actively influencing the flows around the rotor blade of the wind turbine on the basis of novel structure-integrated fluidic actuators, which allow an adaptation of the aerodynamics. Essential components of these developments are both novel actuator and control concepts as well as innovative strategies for integrating the actuators and additionally required components, such as electronics and sensors.

Within the project, the professorship of Management Accounting and Control is especially in charge of analyzing the economic benefits of the developed technologies and the resulting wind turbine system by development concurrent and final assessments in order to support the achievement of the targeted innovation success. This task comprises the following key activities:

- Development and application of an evaluation concept and methodologies for Life Cycle Profit Modeling, Analysis and Forecasting

- Development and application of a concept for the management of innovation success, which includes Life Cycle Target Costing as well as approaches of business model development and simulation

- Development and application of a methodology for the analysis and mitigation of economic risks

Project homepage: FiberCer

The project "Enhancement of Life Cycle Engineering Methodology by Integration of Management-related Methods and its Application to Complex Systems" is supported by the DAAD with funds of the German Federal Ministry of Education and Research (BMBF) as well as the Rectors Council of Portuguese Universities (CRUP) and performed within the DAAD program "Projektbezogener Personenaustausch mit Portugal (PPP Portugal)".

In cooperation with the Instituto Superior Técnico (IST), Universidade de Lisboa (Portugal) it is aimed to the further development of a Life Cycle Engineering and Management (LCEM) framework for a life cycle-related analysis, evaluation, and design of products, processes, and resources from a technical, ecological, and economic point of view. For this purpose, four sub-targets are defined:

- Improvement of the theoretical foundation of Life Cycle Engineering and LCEM by identification and conceptual integration of appropriate engineering, management-related, ecological, system-theoretical, as well as decision-theoretical theory elements into the framework

- Extension of the methodology by specification, combination with established techniques of Life Cycle Engineering, and application of concepts and methods of Target Costing, Supply Chain Costing, Business Modeling, Eco-Efficiency, and Material Flow Cost Accounting to strengthen the market-, customer- and supply chain-orientation of LCE and to elaborate a theoretical contribution to the development of sustainable products, processes, resources, and business models which can be used in corporate practices

- Enlargement of the application fields of LCEM towards complex systems; relevant fields of application with high potential for strengthening sustainability are, e.g., additive manufacturing of composites, injection molding techniques, as well as innovative sports equipment, hybrid railcars, and wind turbines

- Enhancement of Curricula of LCEM and their refinement supported by educational material and elaborated case studies

As the framework structures manifold LCEM-relevant issues and provides recommendations for analysis, evaluation, and design activities, it is intended to be a work base for researchers and practitioners and to contribute substantially to the advancement of sustainable practices.

supported by the DAAD with funds of the German Federal Ministry of Education and Research (BMBF)

supported by the DAAD with funds of the German Federal Ministry of Education and Research (BMBF)  Instituto Superior Técnico is supported by funds of the Rectors Council of Portuguese Universities (CRUP)

Instituto Superior Técnico is supported by funds of the Rectors Council of Portuguese Universities (CRUP)Entwicklung der notwendigen Modifikationen eines Bestandsverbrennungstriebwagens unter Verwendung innovativer Antriebs-, Leit- und Nebenverbrauchstechnik in Verbindung mit einem anforderungsgerechten Energiemanagement zur Sicherstellung eines ökologisch und ökonomisch nachhaltigen Eisenbahnbetriebs in der Region

'EcoTrain' is a joint research project within the nationwide project "Förderprogramm Modellregionen Elektromobilität" with the participation of DB RegioNetz GmbH, Fraunhofer-Institut für Verkehrs- und Infrastruktursysteme, Technische Universität Dresden, and Technische Universität Chemnitz.

The project aims at the new and further development of hybrid technologies for railway vehicles. With innovative traction, control and auxiliary consumer technology and an energy management that meets the given requirements it particularly contributes to a resource-efficient and low-emission operation of diesel railcars.

The professorship of Management Accounting and Control is especially in charge of supporting and proving the achievement of the aspired levels of economic and ecological efficiency. Therefore, development concurrent and final assessments of the developed 'EcoTrain' are conducted. This task comprises the following key activities:

- analyzing the life cycle of (hybrid) railcars and developing appropriate description models

- developing concepts for the integrated economic and ecological assessment of (hybrid) railcars based on Life Cycle Costing (LCC) and Life Cycle Assessment (LCA)

- performing integrated LCC-LCA studies to assess (hybrid) railcars

- deducing further optimization potentials to improve the sustainability of (hybrid) railcars

Consequently, a comprehensive instrument for the consistent assessment of economic and ecological impacts of (hybrid) railcars will be developed. This instrument also contributes to revealing trade-offs between both evaluation dimensions. Therefore, it helps to avoid shortcomings in planning and developing railway vehicles and to increase the competitiveness of hybrid technology in rail industry basing on solutions that are sustainable not only from an ecological point of view but also from an economic one.

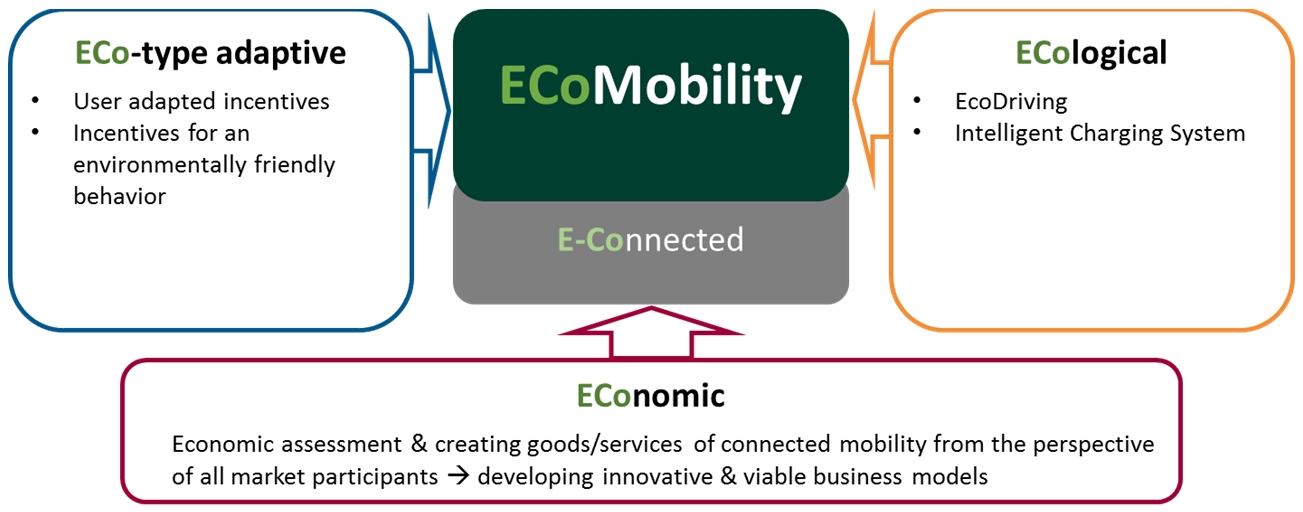

The project ECoMobility dealed with requirements, problems and innovative solutions for the integration of different mobility providers (e.g. private vehicles, commercial fleets, e-bikes and public transport). Beside the professorship of Management Accounting and Control also the professorships of Cognitive and Engineering Psychology, Industrial Engineering and Innovation Management, Power Engineering and High Voltage Technology, Communications Engineering as well as Circuit and System Design were involved in the interdisciplinary research group. The project was funded by the European Social Fund (ESF) through the European Union and the Free State of Saxony (project manager Sächsische AufbauBank).

The objective of the project was to establish an internally connected mobility offer consisting of electric vehicles, pedelecs and public transport. Focusing on the development, connection and evaluation of innovative solutions ECoMobility was divided into the three interdependent emphases Human Factors, ECological and EConomic:

More information here: http://www.sfb692.tu-chemnitz.de/

The project "Life Cycle Engineering und Management Framework" was supported by the DAAD with funds of the German Federal Ministry of Education and Research (BMBF) as well as the Rectors Council of Portuguese Universities (CRUP) and performed within the DAAD program "Projektbezogener Personenaustausch mit Portugal (PPP Portugal)".

In cooperation with the Instituto Superior Técnico (IST), Universidade de Lisboa (Portugal) it was aimed to develop a Life Cycle Engineering and Management (LCEM) framework for a life cycle-related analysis, evaluation, and design of products, processes, and resources from a technical, ecological, and economic point of view. Thus, the primarily engineering-dominated approach of Life Cycle Engineering was extended by a profound consideration of economic principles and methodological elements, among others for a situation-specific preparation of decisions.

NeMoS was one of about 40 projects within the Schaufenster Bayern-Sachsen "ELEKTROMOBILITÄT VERBINDET" and it was funded by the Free State of Saxony in the context of the federal government's "Schaufenster-Initiative". Beside the professorship of Management Accounting and Control also the professorships of Communications Engineering, Circuit and System Design, Media Informatics, Cognitive and Engineering Psychology of the Technische Universität Chemnitz, and professorships of further Saxony education institutions (University of Applied Sciences Mittweida, Technische Universität Dresden, University of Applied Sciences Zwickau and University of Cooperative Education Glauchau) were involved in the project. Coordinated by the MUGLER AG and supported by the Verkehrssicherheitszentrum am Sachsenring GmbH & Co. KG and the Vodafone GmbH the project partner from different disciplines were doing research on various issues in the field of new mobility. This concerned the safety and energy efficiency of electric vehicles, the reliability of energy and communication infrastructure, the users and their behavior as well as the cost effectiveness of electromobility-related supply chains.

The last-mentioned area of research was processed by the professorship of Management Accounting and Control. Innovative products and services are an important brick for the long-term success of electromobility resp. new mobility. For the development as well as the commercialization of these products and services, especially the creation of competitive supply chains is necessary. Therefore, the cost effectiveness and profitability from the perspective of all actors in the supply chain should be ensured. For this purpose, a system of models for forecasting and analysing future developments of integrated electric energy, communication and traffic networks was drafted. In addition, a methodology was developed which is suited for long-term economic analysis and creation of novel products and services in the field of electromobility and new mobility. Beyond that, the profitability of an involvement in electromobile supply chains was evaluated. The models and methods were exemplarily applied to selected issues arising from other areas of research in NeMoS. Based on this, starting points for specific improvements for the life cycle-related cost effectiveness and profitability were derived.

For more information: http://www.elektromobilitaet-verbindet.de/projekte/freiluftlabor-sachsenring.html (German)

The French Environment and Energy Management Agency (ADEME) is a public agency under the joint authority of several French ministries. Among others, ADEME aims for a better understanding of the linkages between business' economics and its environmental and energy performance in order to develop and provide tools and best practices contributing to the transition towards a cleaner and more sustainable production.

Concerning environmental criteria, ADEME has a long track record of assessing and mitigating environmental impacts and now conducts studies on multi-criteria assessments of the life cycle of products in many areas. Focusing on production and taking into account the economic dimension, ADEME initialized some large-scale studies aiming at the evaluation of waste reduction and energy minimization measures.

In its search for more advanced tools and efficient assessment methodologies, ADEME is now interested in testing the combination of tools from different 'worlds' such as environmental management accounting (EMA) and LEAN. The goal of the present project was finding synergies and benefits of combining the EMA tools material flow cost accounting (MFCA) and its extension to energy – material and energy flow cost accounting (MEFCA) –, and the value stream mapping (VSM), which is a LEAN tool.

The central hypotheses were that (1) combining the differing perspectives on processes and the differing definitions of waste could result in a more comprehensive analysis and contribute to identifying the main causes of waste generation. (2) The efforts of modeling and data acquisition can be pooled between the tools, which could enhance the efficiency of their parallel application.

The project includes two case studies from the food-processing sector. Both in-depth analyses were conducted by Ernst & Young, Climate Change and Sustainability Services, which has, among others, a widespread experience in applying EMA and LEAN tools. The task of the professorship of Management Accounting and Control (Technische Universität Chemnitz) was to provide scientific supervision and support.

The parallel application of M(E)FCA and VSM showed similar results for both case studies:

- M(E)FCA and VSM identified the same (sub-)processes as major weak points, but in some cases for different reasons.

- Applying the two methods in parallel results, to a certain degree, in differing basic models of the system under consideration, which causes some double work and limits the comparability of results. Thus, using a more integrative approach of M(E)FCA and VSM is highly recommended. However, the development of such integrative approach was not part of the project.

- The analysis of material and in particular that of energy (loss) flows is time-consuming since much of the data needed is not available or at least not at the desired level of detail – and, for the present project, an analysis on the process level was stipulated. For future M(E)FCA applications the use of a more rough pre-study identifying the most critical areas is recommended.

- In both case studies, the stipulated analysis of energy flows was quite laborious, but the respective economic saving potentials were low from the outset because the share of total energy cost was negligible. Nonetheless, the quantitative share of energy losses in particular of supporting processes (air conditioning, heating, cooling etc.) was found to be very high. Thus, at least one of the companies will consider energy efficiency to a greater extent in future investment decisions.

Since there were only two case studies from a single industrial branch, the project's results can of course not be generalized. Moreover, both companies were involved in former waste reduction projects and, thus most of the (remaining) weak points regarding material waste were known already.

A critical point is that – in these specific case studies – the application of a second approach did not reveal more areas for improvement. However, the understanding of the root causes of material and energy losses was enhanced by contrasting the M(E)FCA results by those of the VSM analysis, which uses a different definition of 'waste' (so called 'muda'). Thus, further research in this area is expected to be fruitful, in particular when addressing an integration of M(E)FCA and VSM that avoids double work regarding modeling and data acquisition. Additionally, such integrated approach should not be limited to the identification of problems but also support the development, selection and implementation of improvement measures.

The project "eBEn – eBusiness Engineering" was a joint research project of the Technische Universität Chemnitz, the RKW Sachsen e. V. and the Terrot GmbH. This project was aimed at the development, validation and application of methods and instruments for a systematic master data and business process management as a basis for improved value creation in small and medium sized companies.

On the part of the Technische Universität Chemnitz an interdisciplinary research team from the chair of design and the chair of management accounting and control developed science-based and -proven basics for a largely company- and industry-independent technology transfer.

For the development of well-founded solution methods and tools (building blocks), a three-phase approach has been chosen. First, with questionnaire-based interviews in 134 small and medium-sized enterprises drivers and barriers for systematic master data management as well as relevant business objectives and constraints regarding the use of eBusiness Engineering and eBusiness Standards, respectively, were identified (phase I). On the basis of the interview results, requirements were collected for the development of building blocks for the general analysis of the master data situation and the related process situation (phase II). Further, derived from the phase I and II results, additional building blocks for detailed analyses and improvement measures (synthesis measures) were developed (phase III). Both, the building blocks of phase II and III were validated in different companies.

Accompanying the master data and process analyses and syntheses, the chair of management accounting and control developed in particular building blocks for cost-benefit analyses in the phases II and III regarding the economic appraisal of the implementation and continuous monitoring of synthesis measures.

Link to the web page of the project: www.eben-tuc.de (German)

The relevance of resource and energy efficiency is increasing in all conceivable application areas and forces therefore the utilization of high strength materials and lightweight concepts. The use of carbon fiber reinforced plastics (CFRP) benefits from this development. But there are also several problems with CFRP's regarding the joinability to other materials as well as the wear properties in comparison to metallic materials. Further potential results from the possibility to insert additional functions in the CFRP, such as electrical or thermal conducivity.

The object of the junior research group TranS-Ver was it therefore to find appropriate solutions for the problem areas mentioned above. By the use of suitable fiber coatings as well as a clever positioning in the matrix it was the aim to generate new materials which provide high strength joints, wear resistant coatings and functional polymer matrix composites. Especially the couting of fibers with copper or nickel-titanium produced interesting results.

For improving the innovation success of these new materials the subproject "Economical transfer" at the Professorship of Management Accounting and Control - that lasted from 1st July 2012 to 30rd June 2014 - designed several methods to identify potential application areas and furthermore to evaluate the commercial potential of the material innovations already in the early material design phases. Of particular importance in this context was the allocation of suitable methods to evaluate the necessary production and manufacturing processes in the future to enable an efficient design of the whole supply chain. Due to this objectives the researcher in the area of business administration and materials science and engineering could - in collaboration - identify promising application areas such as shielded CFRP's in aeroplanes and rotor blades in wind turbines. Furthermore relevant processes concerning the manufacturing of these components have been monetary evaluated.

The project was realized in cooperation with the Institute of Materials Science and Engineering and the Professorship of Assembly and Handling Technology.

For more information: http://www.tu-chemnitz.de/TranS-Ver/index.php.en

For more information: http://www.eniprod.tu-chemnitz.de/ (German)

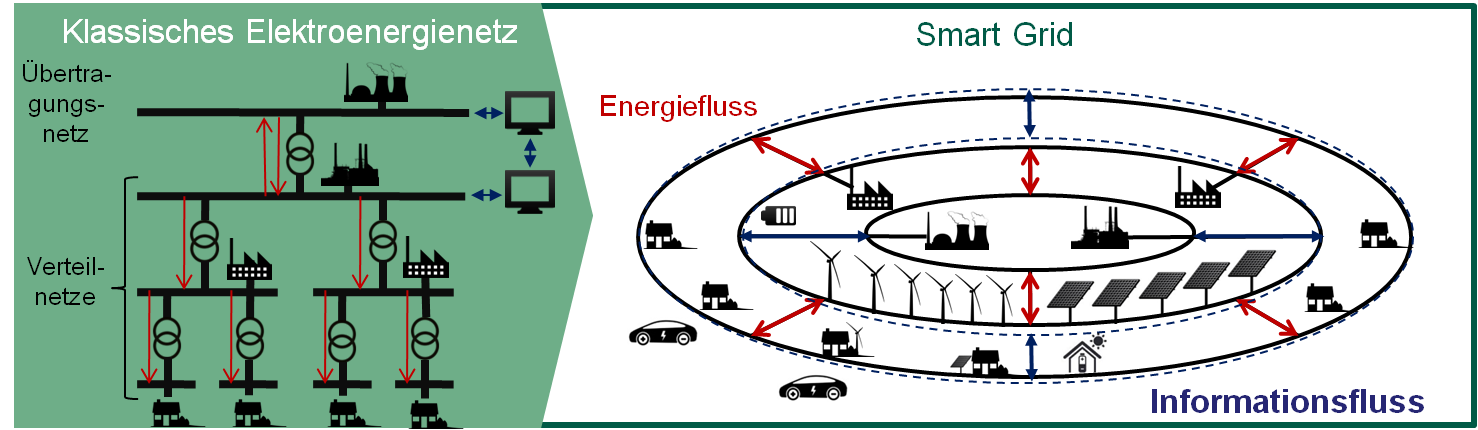

The objective of this project that was funded by the European Social Fund (ESF) and the the Free State of Saxony was the development of a scientifically sound economical approach for explanation and composition regarding the linkage of different forms of networks. An analysis of the currently existing real infrastructure networks and the applied modelling approaches shall provide the basis for this. The approach shall enable the evaluation and control of the economic profitability of products, business models and value chains resulting from the network linkage.

The result of the research project ist an strategic management approach for changing value structures. Its essential core element is a developed analysis and forecasting tool for fundamentally changing value structures. Therewith effects on single enterprises, value networks oder whole industry sectors can be defined and recommended actions can be derived in a strategic management process.

The project was supported by MUGLER AG, a medium-sized telecom company from the Chemnitz-Zwickau region. The objective was also to strengthen the competitive capability of Saxon economy in trend-setting future markets by a knowledge transfer with cooperation partners and young academics. The subject is currently proceeded in a PhD project an the Professorship of Management Accounting and Control.

The essential objective of this interdisciplinary research project that was funded by the European Social Fund (ESF) was the development of an innovative process for serial production of 3D-contoured thermoplastic sandwich structures (fibre-reinforced plastics).

A fundamental subgoal of this research project that was elaborated within the subpoject 4 at the Professorship of Management Accounting and Control was the designing of a system to assess and enhance the life cycle profit of lightweight components. As a result, a model was developed that can be used both to estimate technology-specific life cycle costs and profits of F.R.P.-structures in early design stages and to identify and quantify non-monetary criteria relevant for success. Therefore the model shall be applied to support F.R.P.-technology decisions.

The cooperation of academics from a technical and an economical field enabled the application of parts of the designed calculating system to the t3S-structures during the development - especially within the scope of case studies with respect to demonstrator components. Thereby, economical aspects like life cycle costs and resulting life cycle profits alongside the whole development and process chain could be considered during the technological process development. This also helps towards the commercial and technological success of the research project itself. Furthermore, the application of life cycle costing to prepare technology decisions regarding innovative F.R.P.-structures and there production processes for industrial users was permitted.

This project was elaborated together with the Department of Lightweight Structures and Polymer Technology and in collaboration with industrial partners like Ghost Bikes GmbH.

For more information: http://www.leichtbau.tu-chemnitz.de/t3s/ (German)

The target of this project was the design and implementation of a holistic, proactive approach to support product costing of sheet metal forming tools over the entire product development process. The main objective was to improve the forecast, the analysis, and the control of tool-costs with regard to accuracy and speed of operation. Furthermore, a knowledge base has been developed to collect the gathered knowledge from customer projects regarding costs, processes, and disturbances in a central data base and make it available for decision making processes in product development and distribution.

As a result, a concept for a product cost management system for tool and mold making was developed including target course, objects, surrounding conditions, tasks, cost drivers, activities, organisation, and instruments as relevant facets. Based on this, a IT-based cost information system - as the instrumental core of the product cost management system - and its components were designed. This IT-tool should provide the calculations and other cost management activities with cost information. Furthermore, necessary steps for its implementation as well as variants for designing business processes and information flow to apply the cost information system in an efficient and effective way have been demonstrated.

This project was elaborated in collaboration with the Siebenwurst Werkzeugbau GmbH and the Professorship of Engineering Design.

The objective of the project was to develop methods, concepts, and best practices for the reduction of variety and complexity within the focus of master data management and product cost management.

For this, the following sub-goals were achieved, referring to product creation and product use within the integrated product development:

- configuration of a (company-neutral) IT-infrastructure for the laboratory for integrated product development to facilitate the development and transfer of methods, concepts, and best practices for the analysis, cleansing, and consolidation of master data as well as for the product cost management,

- development and testing of methods, concepts, and best practices (demonstrators) for the analysis, cleansing, and consolidation of master data as well as for the product cost management to enable the configuration of specific solutions for a wide range of SME with differences in tasks and boundary conditions (toolboxes),

- development of an approach (consisting of three steps, target group related) for transferring the results in SME,

- development of training modules (regarding, among other things, economical product design, methodical engineering, target costing, and knowledge management within target costing) comprising the ongoing requirements of industry.

This project was processed in cooperation with the professorship of design theory of Technische Universität Chemnitz. It was funded by the European Union (European Regional Development Fund) and the Free State of Saxony.

For more information: www.ipe-lab.de (German)

The objective of the project was to develop a concept of modelling, recording and analysing the total costs of radio network and radio station infrastructure. Based on this concept, measures improving the cost efficiency shall be developed in order to enable an optimal design of existing and future radio network and radio station infrastructure.

The achievement of this objective required the specification of general theoretical findings, methods and models with regard to the characteristics of radio stations and radio networks. Furthermore it involved developing a generic model of the life cycles of radio sites and radio networks with a high level of detail to the point of individual processes. On this basis, life cycle costs and their influencing variables shall be identified and systematized. Differentiated (partial) models had to be formulated in order to analyse specific issues and address problems in decision-making. These models were adopted and tested by using specific calculation methods and statistical techniques.

Furthermore the research projects aimed to identify various parameters of stations and networks as well as their relationship. This information is required within the framework of systematic design of life cycle costs of radio network infrastructures.

This third-party funded project was processed in cooperation with the MUGLER AG and funded by the European Regional Development Fund (and the state of Saxony). Within a dissertation project the topic is called up through further processing.