Close to Fiction: the Hull Material of the “Starship Enterprise”?

Chemnitz University Professorship of Materials and Surface Engineering commences operation of a new laser deposit welding system – processing functional iron-based metallic glasses

-

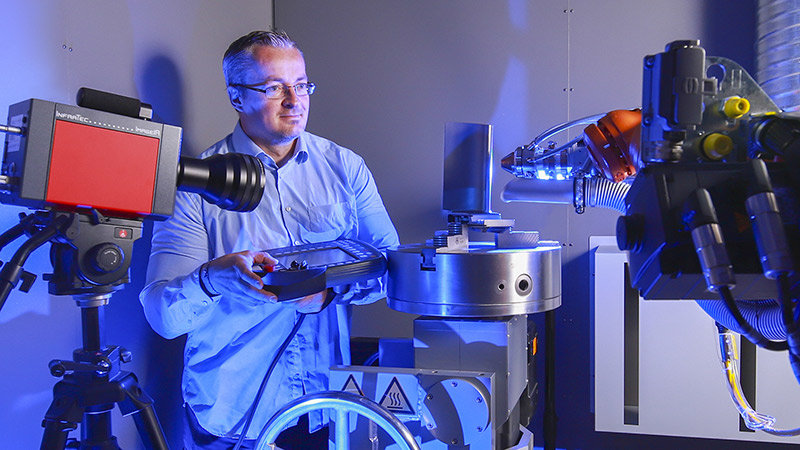

Gerd Paczkowski, research staff member at the Professorship of Materials and Surface Engineering, aligns the laser head and high speed thermography camera with a turbine blade. Photo: Jacob Mülle -

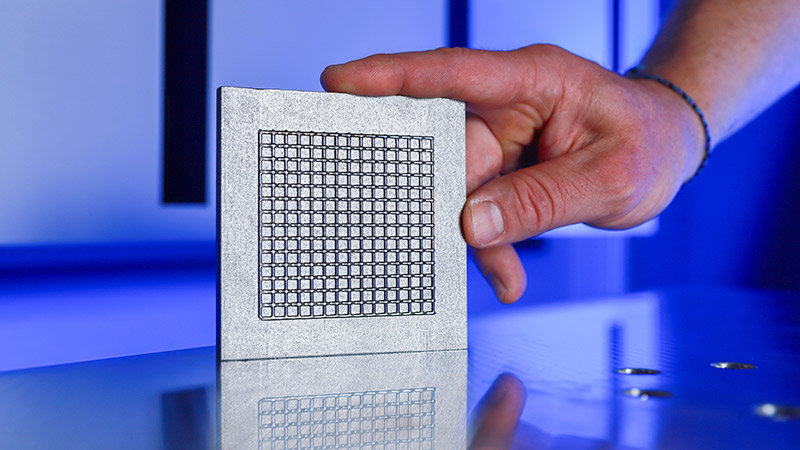

Various metallic materials can be processed using the new Lasercladding system. Shown here is an iron-nickel-phosphorous-carbon alloy. In practice, it is referred to as a metallic glass and has a relatively high plastic ductility. Photo: Jacob Müller -

During the ceremony to celebrate the commissioning of the new welding system, Prof. Dr. Thomas Lampke (left), Head of the Professorship of Materials and Surface Engineering, explains Lasercladding to the President of Chemnitz University, Prof. Dr. Gerd Strohmeier, using the example of a turbine blade. Photo: Jacob Müller -

During the commissioning ceremony, a great deal of interest in the new system was expressed by guests from the university, from other higher education institutions and from industry representatives. Photo: Jacob Müller -

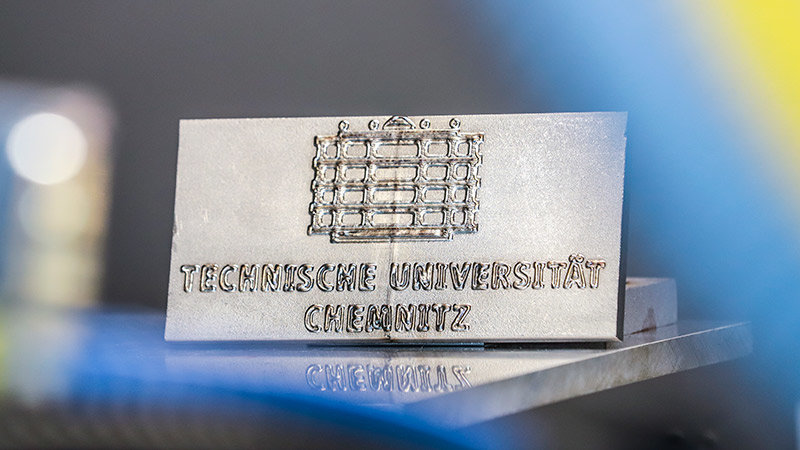

Using Lasercladding by which metallic glass is applied to stainless steel, the Chemnitz University logo can truly be allowed to shine. Photo: Jacob Müller

With the application of metallic glasses, under the direction of Prof. Dr. Thomas Lampke, the Professorship of Materials and Surface Engineering has advanced into the top echelon of laser deposit welding ("laser cladding"). The professorship has completed their existing infrastructure for thermal coating with this new welding system from Lunovu GmbH. “The use of high-performance materials and their application in surface functionalization will considerably strengthen the key research area of ‘Lightweight Construction with Steel’” says Lampke.

Continuous Coating of Geometrically Complex Surfaces

The system integration approach involves the precise combination of various materials and property profiles within a layer system. “With virtually no issues, we could now functionalize the exterior of a future spaceship like the Starship Enterprise, so that it combines the advantages of metals, polymers, ceramics, glasses and carbides,” says Gerd Paczkowski, research staff member at the Professorship of Materials and Surface Engineering, with a grin. Aside from this fictional application, laser deposit welding can be used in situations where expensive or large elements need to be protected from wear or repaired without compromising their value. This includes, for example, engine or turbine elements, hydraulic components and anilox rolls. laser deposit welding is a process by which a particulate filler metal is melted at the focal point of the powder nozzle using a specially-calibrated laser and is then deposited in layers onto the element’s surface. “With the planned integration of a 3D line scanner in the robotic control system, it will be possible to continuously coat geometrically complex surfaces,” assures Lampke.

High Speed Thermography Balances the Heat Input in Materials Exactly

The system in the Chemnitz University laboratory has several special features: “The laser output of the 4 kW diode laser in our system is controlled using software via a high speed pyrometer. The temperature input in the substrate is taken into account as a mathematical factor during the coating process, in order to avoid hot spots and to keep the seam or layer quality constant, even when dealing with large surface areas,” explains Lampke. This is essential when working with so-called cluster materials or metallic glasses, since the energy input needs to be minimal in order to suppress crystallization that may occur as a result of a prolonged cooling period. “In addition, the system is capable of high speed thermography. With the corresponding camera, made by InfraTec in Dresden, which is currently one of the fastest on the market, we can quantify the exact heat input of the laser into the material,” assures Paczkowski. It is no wonder, then, that this technical equipment has already been applied in national and international research projects in cooperation with the industrial sector. Additional basic and application-oriented projects are also currently in preparation. The laser technology will also be integrated in the Collaborative Research Center, which is operating under the working title of “High Performance Steel.”

Researchers and Students in Many Fields at Chemnitz University Can Use the System

The new equipment will especially benefit students of Mechanical Engineering, Automobile Production and Advanced Functional Materials. “Beginning in the 2018/2019 winter semester, the internship in thermal coating will be expanded to include the technology of laser coating with functional properties,” reports Lampke.

The laser deposit welding system and the peripheral analytic equipment receives equal funding totaling 600,000 euros from the German Research Foundation (DFG) and the Free State of Saxony. Supporters of the proposal and future co-users include the Chemnitz University Professorships of Inorganic Chemistry, Microsystems and Biomedical Engineering, Lightweight Structures / Polymer Technology and Composites and Material Compounds. “Of course we are also open to working with other professorships at our university,” says Lampke to conclude his remarks on the new system.

Commissioning Ceremony

The official commissioning ceremony for the laser deposit welding system was held on June 21, 2018. Guests included the President of Chemnitz University of Technology, Prof. Dr. Gerd Strohmeier, Professors from the Faculty of Mechanical Engineering, members of University Management and representatives from the industrial sector, unions and educational institutions.

More information about the new laser deposit welding system is available from Gerd Paczkowski, Tel.: 0371 531-37887, E-mail: gerd.paczkowski@mb.tu-chemnitz.de

(Translation: Sarah Wilson)

Matthias Fejes

27.06.2018