Eight million euros for research on intelligent components

The German Research Foundation will continue to fund scientists from Saxony and Bavaria for another four years - the project led by TU Chemnitz

-

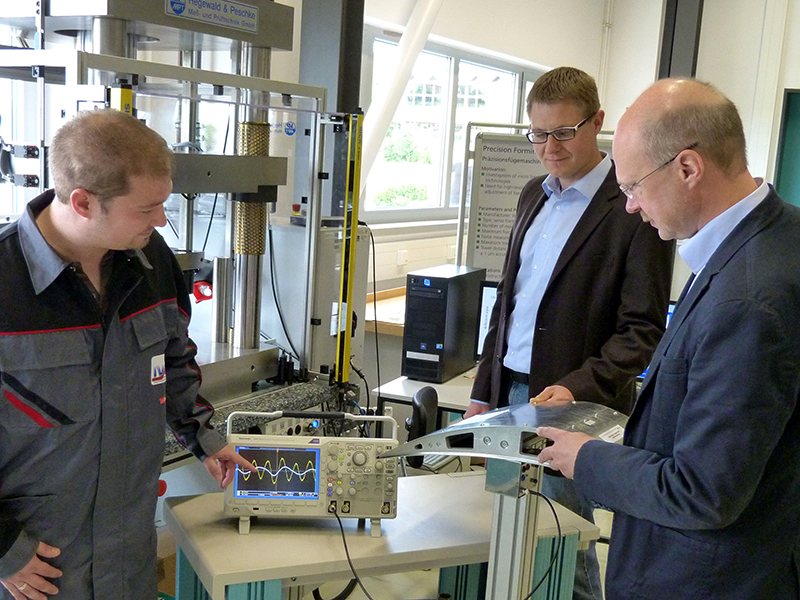

Prof. Dr. Welf-Guntram Drossel (on the right), the spokesman of CRC/TR 39, and Michael Müller (in the center), designated managing director of CRC/TR 39, discuss with Benedikt Müller, a member of TU Chemnitz, the sensor-actuator of a formed sheet metal component. Photo: Fraunhofer IWU/Matthias Nestler

In the automotive and aviation industry are steadily increasing requirements for comfort and safety. Nowadays, the built-in sensors, actuators, and the insulating materials to reduce noise, make up a significant proportion of the total weight. "In the future it is important to achieve a reduction or at least maintaining the weight of automobiles and airplanes by functional integration," explains Prof. Dr. Welf-Guntram Drossel, the Head of the Professorship for Adaptronics and Light-weight Design in Production at Technische Universität Chemnitz and the spokesman of the Collaborative Research Center/Transregio (CRC/TR) 39.

Since 2006, under the management of TU Chemnitz, the research scientists from Chemnitz, Dresden and Erlangen have been funded on intelligent sheet metal parts and composite parts. The German Research Foundation (DFG) has already funded CRC/TR 39 with around 17 million euros. Due to convincing results and innovative ideas, the DFG will continue funding of the project for another four years with around eight million euros. From July 2014 to June 2018 are to be researched a total of 18 subprojects with 22 scientists and 21 PhD students under the title "Production Technologies for light metal and fiber reinforced composite based components with integrated PIEzoceramic Sensors and Actuators" - short "PT-PIESA". The idea is, to work out scientific fundamentals for an economic production of active structural components. "In contrast to today`s systems, sensors and actuators are part of the material structure. Thus, additional functions cause no extra weight. On the contrary, they allow a further weight reduction," explains Prof. Drossel and adds: "The potential of the technologies previously developed within CRC/TR is enormous."

The evaluation of the Collaborative Research Center by the DFG reviewers was shown what is already possible with this technology. Thus, a noise reduction is achieved by thin active aluminum sheet metal parts, which is otherwise only possible by use of heavy insulating materials. A prototype of an aircraft wing demonstrates the potential for aviation. Integrated sensors and actuators detect early damage in the component, which can help to avoid serious accidents.

"At the Collaborative Research Center/Transregio we have the opportunity to jointly cooperate with the best scientists in the relevant subject areas, and to cope with interdisciplinary challenges of functional integration," said Prof. Drossel. Praised was particularly the outstanding integration of the scientists of TU Chemnitz, TU Dresden, FAU Erlangen-Nürnberg and such non-university research institutes the Fraunhofer Institute for Machine Tools and Forming Technology IWU in Chemnitz, the Bavarian Laser Center in Erlangen as well as the Fraunhofer Institute for Ceramic Technologies and Systems IKTS in Dresden. Target is to make the technologies for industrial production application ready for use up to 2018. From this perspective, the achieved results have so far convinced not only the DFG reviewers, but also attracted the interest of industry partners. Among other things, Mercedes Benz AMG, KraussMaffei and ThyssenKrupp den Transfer plan the transfer of research results into their products.

More information is available from the spokesman of the Collaborative Research Center/Transregio 39, Prof. Dr. Welf-Guntram Drossel, Phone +49 371 531-23560, Email adaptronik@mb.tu-chemnitz.de, and Michael Müller, Phone +49 371 531-37859, Email pt-piesa-gs@mb.tu-chemnitz.de.

(Author: Mario Steinebach, Translation: Nataliia Boiko)

Katharina Thehos

22.05.2014