Waste from the mill goes towards new material

Department of Hoisting and Conveying Engineering has developed a new plastic compound in collaboration with local businesses - 60 per cent is made up of a renewable raw material: oat hulls

-

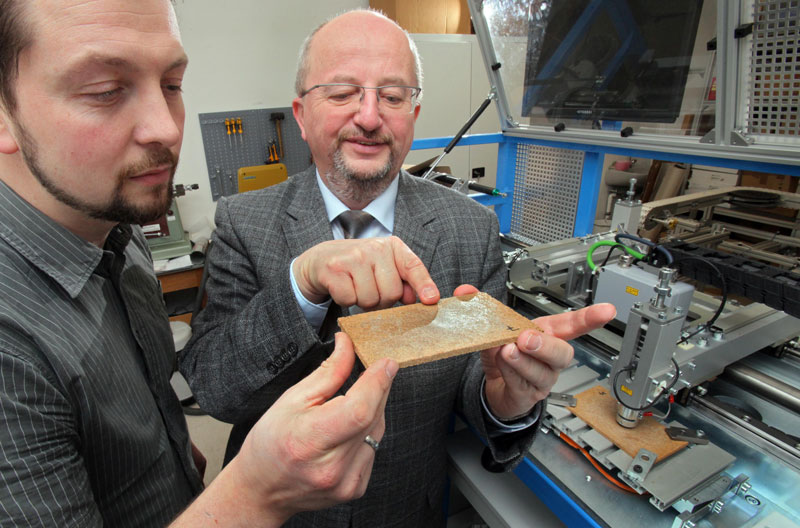

Prof. Dr. Klaus Nendel (r.) and Kay Cramer of the Department of Hoisting and Conveying Engineering at the Chemnitz University of Technology discussing the results of trials at the friction testing station. Photo: Uwe Meinhold -

The plastic compound containing oat hulls demonstrated distinct advantages when tested for friction and wear resistance. Photo: Uwe Meinhold

In bakeries, oat hulls prevent the dough from remaining sticky and from burning in the oven. "There are no other uses for them at the moment," says Prof. Dr. Klaus Nendel, chair of the Hoisting and Conveying Engineering Department at the Chemnitz University of Technology. "This is a waste product that cannot be used for food or as animal feed." Researchers at the university realized from the use of oat hulls in bread making that they were more heat-resistant than many other renewable resources which are integrated into plastics to make them more stable. "A problem often occurs during processing, with the renewable materials suffering damage when exposed to temperatures above about 160 to 180 degrees Celsius. But oat hulls can withstand temperatures up to 220 degrees Celsius."

The hulls are separated from the oats before the grains are crushed during processing. They are combined with plastics to make a compound, from which parts can be made. Conveying engineers at the university worked with companies from the Chemnitz region to manufacture them: C.F. Rolle GmbH prepared the hulls at its mill in Waldkirchen, where the material was then dried and chopped, CKT Kunststofftechnik GmbH from Mittweida produced the compound, and Kunststofftechnik Weißbach GmbH from Gornau was responsible for processing it into trial parts. These then underwent extensive testing in the laboratories at the University of Technology.

A blend of polyethylene with 60 per cent hulls proved to be the best combination. The new material demonstrated distinct advantages when tested for friction and wear resistance. The results showed that not only did the parts made with the oat hull compound exhibit less wear, but that the matching steel and plastic components used against them in the friction tests also did. There are some disadvantages relating to its mechanical characteristics at this stage in the research, and the material is also unsuitable for applications where there are major fluctuations in air humidity, as the hulls can swell up. "However, the advantages should generate significant technical added value, as long as the limits we have calculated are observed," says Nendel.

The components will also be better value for money, as oat hulls are cheaper than plastic. "It`s realistic to talk about cost savings of about 30 per cent," Nendel says. The compound could be especially useful in areas where tribological issues can open the way to potential energy savings - and would therefore include material handling. "As far as friction and wear are concerned there`s plenty of room for improvement in the plastic guide rails currently being used," says Nendel. At the moment researchers are working to produce large semi-finished parts instead of small trial parts.

This project was funded by the German Federal Ministry of Economics and was run under the auspices of the Otto von Guericke Consortium of Industrial Research Institutes (Arbeitsgemeinschaft industrieller Forschungseinrichtungen "Otto von Guericke" e.V.).

(Source: Magazine "Produktionstechnik 2012", translated by SprachUnion Chemnitz)

Katharina Thehos

29.03.2012