RopeRobot - large-scale cable robotics for the automated maintenance of urban vertical gardens

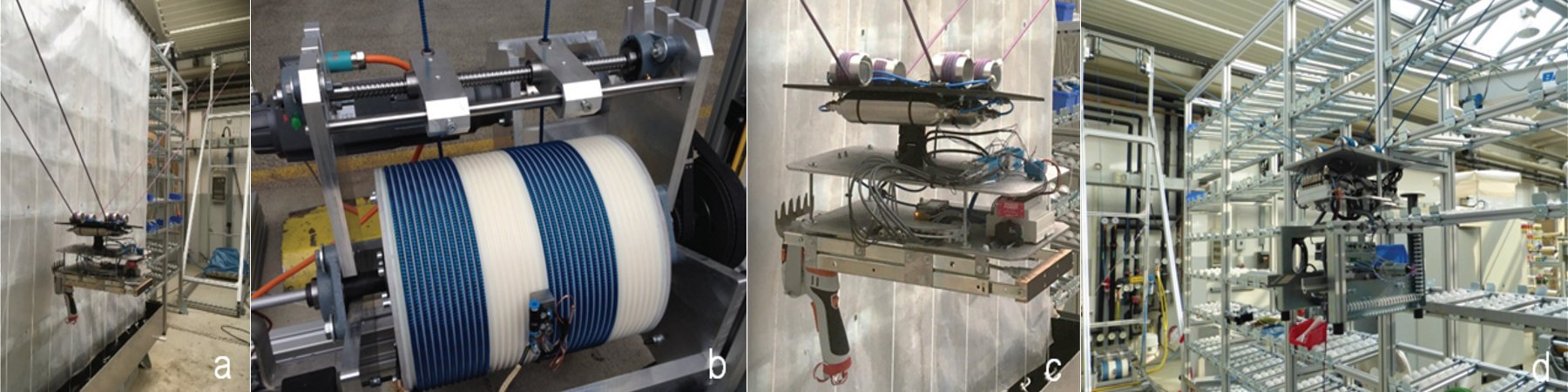

In recent years, the Chemnitz University of Technology has developed the concept of a non-redundant guyed cable robot for large-scale applications (Image 3). A medium-carrying, high-strength fiber rope was developed for this purpose (Table 1). This cable enables the transport of electrical energy, control signals and fluid delivery between the drives of the system and the respective actuators on the end effector.

The developed fiber ropes were successfully tested in a demonstrator, whereby the trailing cables that were previously required can be completely eliminated. This means that highly dynamic applications are possible. Geometric disturbances caused by collisions of the trailing cables in the work area are eliminated.

Cable kinematics are therefore more flexible and can be used in larger areas of application than conventional inherent kinematic handling systems. The proof of function was provided using several different end effectors at the system level. End effectors for the maintenance of vertical greenery (images 3a and 3c) and for order picking on flow rack systems (image 3d) were developed and successfully tested on a laboratory scale. Furthermore, system components such as the drives with media feed and media splitters as well as the media-carrying cable were developed and extensively tested.

Das System kann sowohl im Innen- als auch im Außenbereich eingesetzt werden (Image 2). Es eignet sich für Arbeitsbreitenn von 5 bis ca. 100 m, ohne dabei Antriebe oder Aktorik am Endeffektor verändern zu müssen. Es sind ebene und räumliche Anwendungen vorstellbar.

| Anforderung | Zielgröße |

|---|---|

| Wiederholbare Positioniergenauigkeit aller Bewegungsachsen | + / - 0,5 cm |

| Arbeitsraum (L x B x H) | 20 x 20 x 5 m |

| Nutzlast der Aktorikplattform | 20 kg |

| Achsgeschwindigkeiten / Achsbeschleunigungen | bis zu 5 m/s / bis zu 10 m/s² |

| Anliegende Medien über medienführendes Seil I | 0,5 l/min (Wasser RT) |

| Anliegende Medien über medienführendes Seil II | 100 l/min (Druckluft bei 6 bar) |

| Anliegende Medien über medienführendes Seil III | 48 V / 3,5 A (elektrische Energieversorgung) |

| Anliegende Medien über medienführendes Seil I&II&III | Ethernet (Übertragung der Steuerungssignale) |

Projektteam

Laufzeit01.05.2021 bis 31.10.2022 |

Gefördert durch

pdf-Version |