Workshops of ET/IT faculty

To ensure continuous operation of research and teaching activities at our faculty, the workshops are able to accept various orders.

Among others, many materials can be processed using different tool equipment, including welding. Surfaces can be lacquered, electrical cabinets can be wired partially or totally, many electrical modules can be projected and manufactured, any sort of electrical devices can be modified, and small batches of printed circuit boards (PCBs) can be assembled.

Our staff will be glad to help you with your project planning, realization and problem solving.

A rich set of electronic components is available for the university staff. Additionally, the workshops of the faculty ET/IT provide a major part in the training programmes for electronic engineers for devices and systems.

The workshops hire twelve trainees.

-

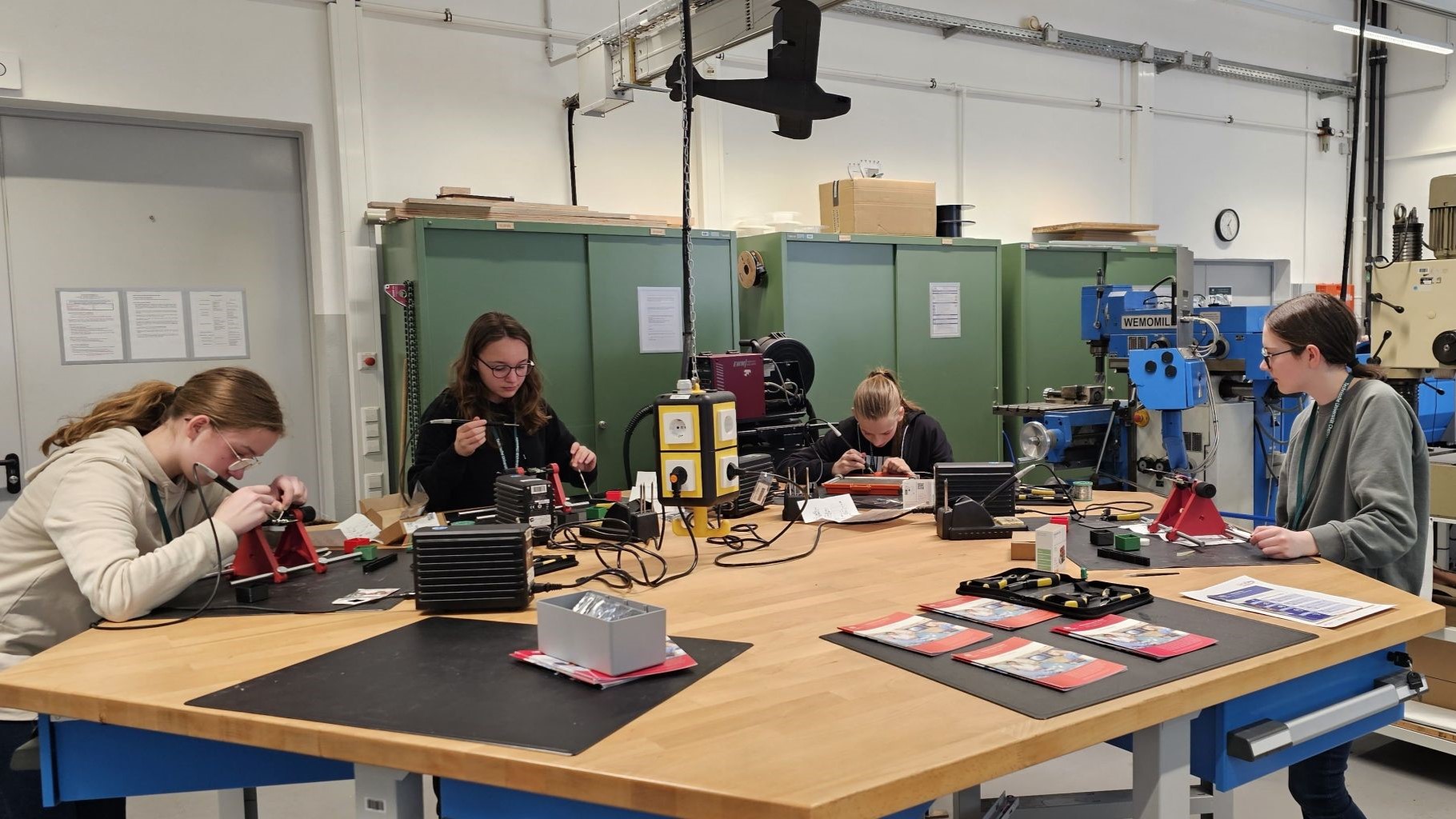

On the occasion of Girls’ Day 2024, Lars Gebhard and Marc Opitz showed interested female students how to weld and solder with their offering "Understanding What Connects!" The resulting figures were allowed to be taken home afterward. (Photo: Susann Kappler) -

Training programme: Trainee Sarmatzki, soldering SMD components and featuring a solder extraction system, an ESD protection armlet, a tweezer, and a soldering station. -

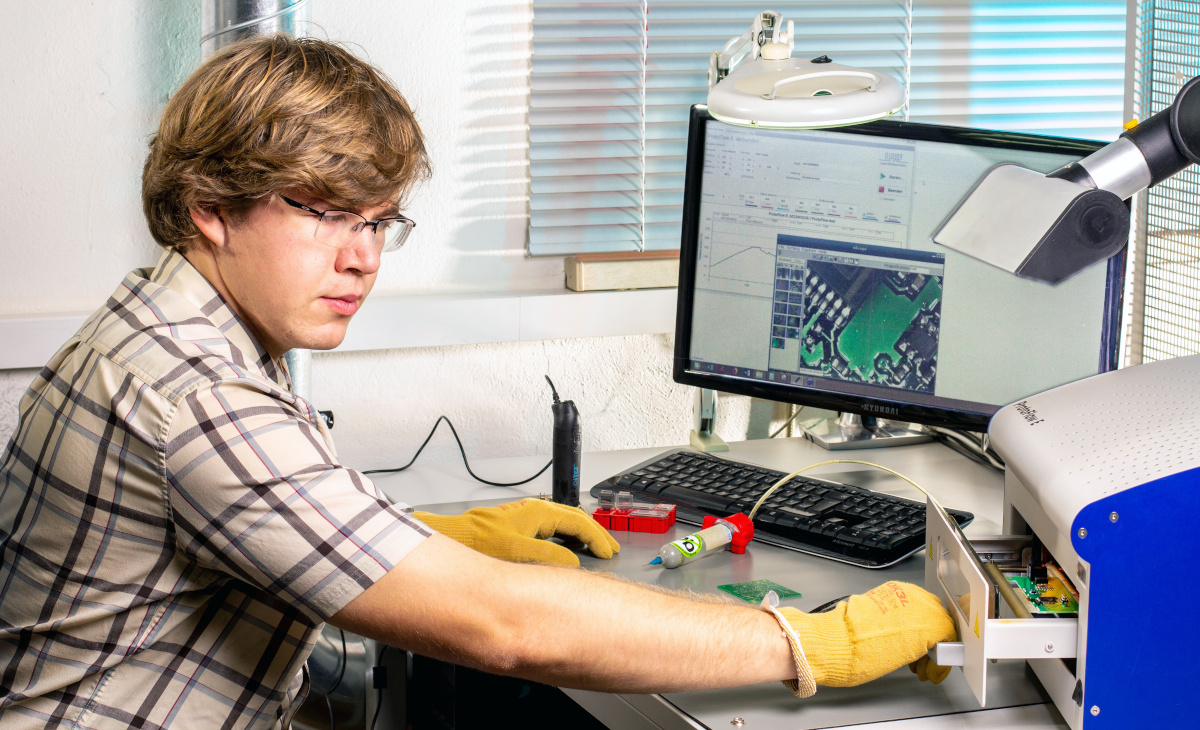

Training programme: Trainee Müller, assembling SMD components using a solder dispenser/reflow oven and USB microscope. After a brief instruction, this working place can also be used by university staff. Or an order is placed in such a way that the workshop staff or trainees will assemble your PCB. -

Training programme: Instructions for a transistor circuit during the second teaching year, by Lars Gebhardt. -

Training programme: Trainee Oberück, working at the self-made coiling machine. By placing an appropriate order, we are able to manufacture coils featuring wire diameters of 0.05mm up to 1.5mm. -

Training programme: Trainee Richter, working at a wire dispenser. The wires can be cut to any length and can be equipped with arbitrary connectors, depending on the order. -

Workshop: Employee Alexander Lippmann, working in the component collection. To be able to process all orders continuously, we keep a small pool of electronical components and devices, and we can also quickly supply components to university staff. The pool features various transistors, resistors, diodes, capacitors, connectors, heatsinks, ICs as well as buttons and switches. -

Workshop: Employee Marc Opitz, checking a device at a box column drill using norm DIN VDE 0701 0702. -

Workshop: Employee Toni Scheibe, working on our new 3-axis CNC milling machine (vertical machining center) and measuring mills. Highly complex 3-D parts, made of aluminium, steel, stainless steel or plastic, can be manufactured on this machine. -

Workshop: Employee Anett Stark, working on an aluminium part using a lathe. -

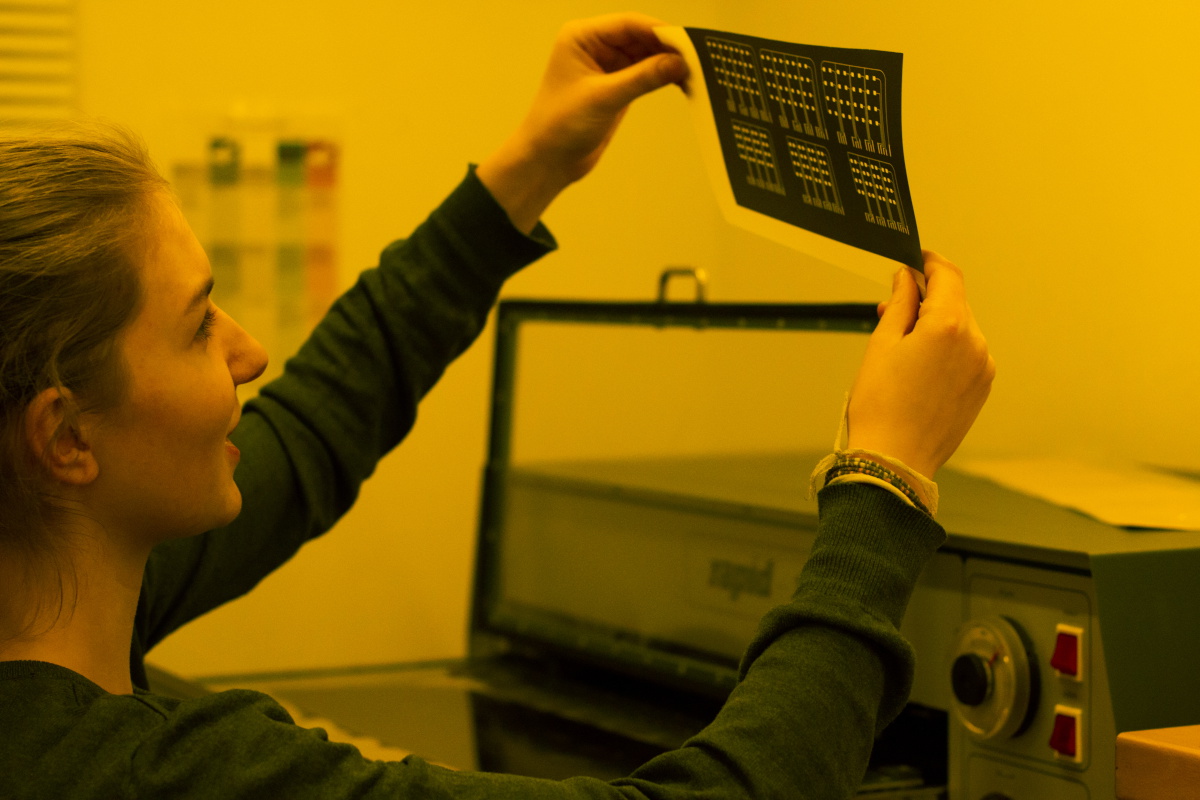

Training programme: Trainee Höß, working in the PCB fabrication. She is holding a layout sheet, which is transferred lithographically (UV light) onto a photosensitive layer on raw PCB material later.