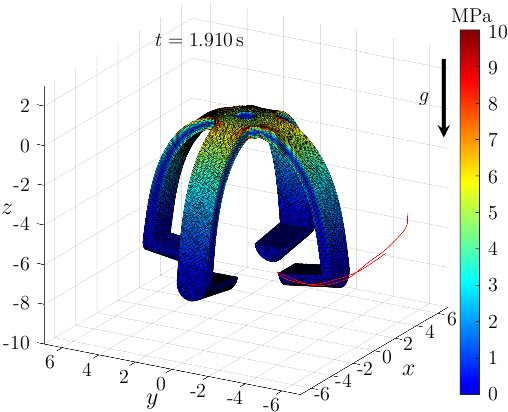

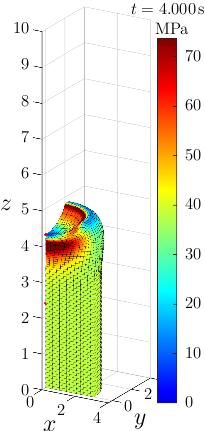

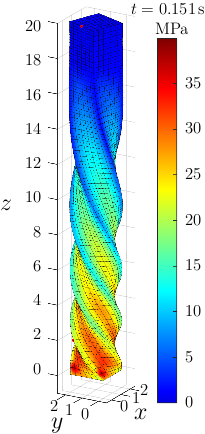

The numerical simulation laboratory is where the numerical practicals for our courses are held. Here, students implement program solutions to eigenvalue problems, linear equations of motion in matrix form, as well as linear and nonlinear finite element methods in space and time for rigid and deformable bodies. The students are given a starting routine, which is completed in the course. In this way, students learn the basic procedure for solving motion equations of all kinds and can better understand the background of commercial software packages. However, the development of new algorithms for finite element (FE) simulation of new problems can also be learned in student projects.

The development of new algorithms for mechanical problems in student projects and research projects is the second way in which our workstations are used in the numerical simulation laboratory. These are new developments that have not yet found their way into commercial software packages, but are necessary for novel problems and for further development. In this laboratory, the staff of the professorship have the opportunity to carry out dynamic long-term simulations efficiently and without interruption.

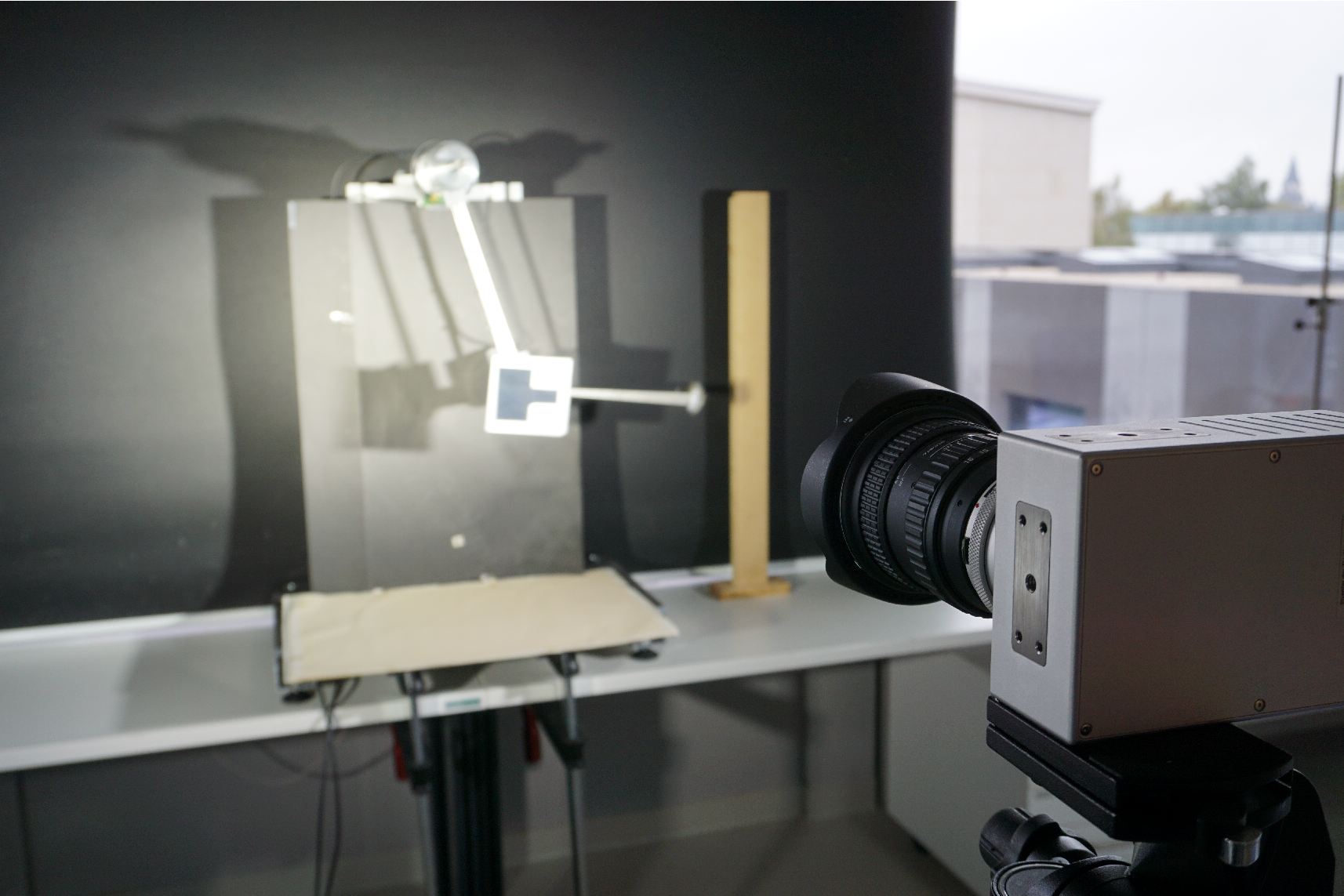

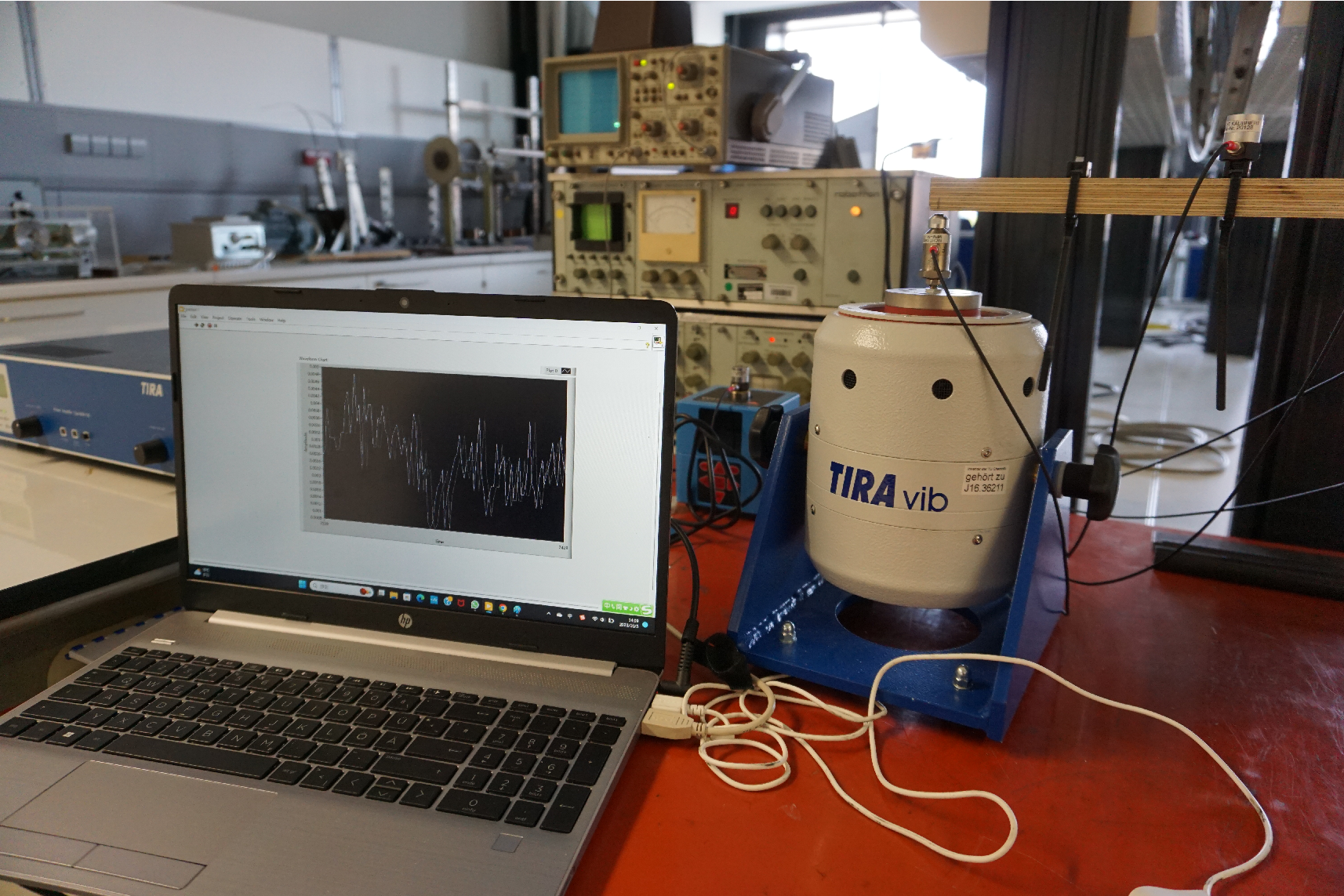

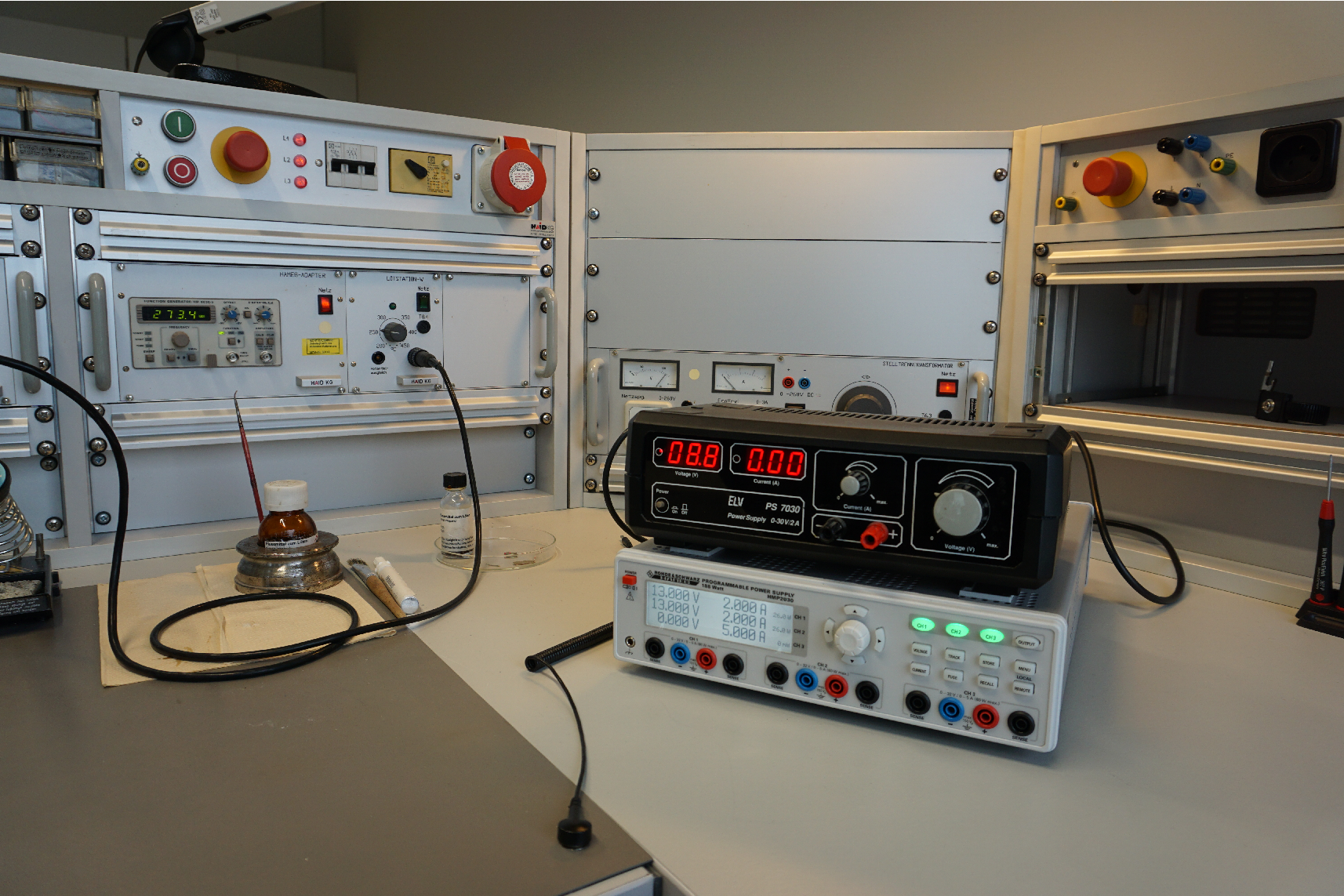

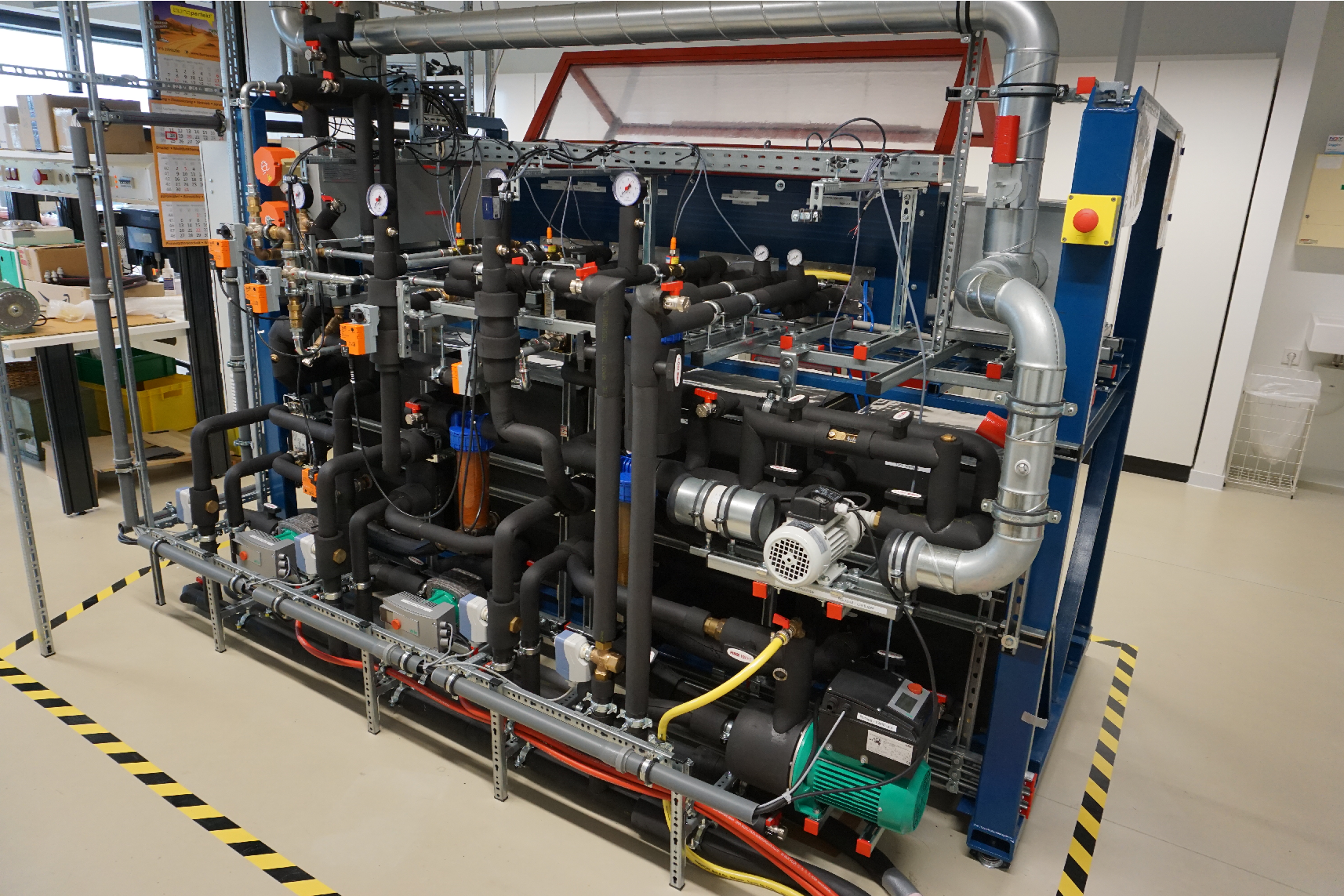

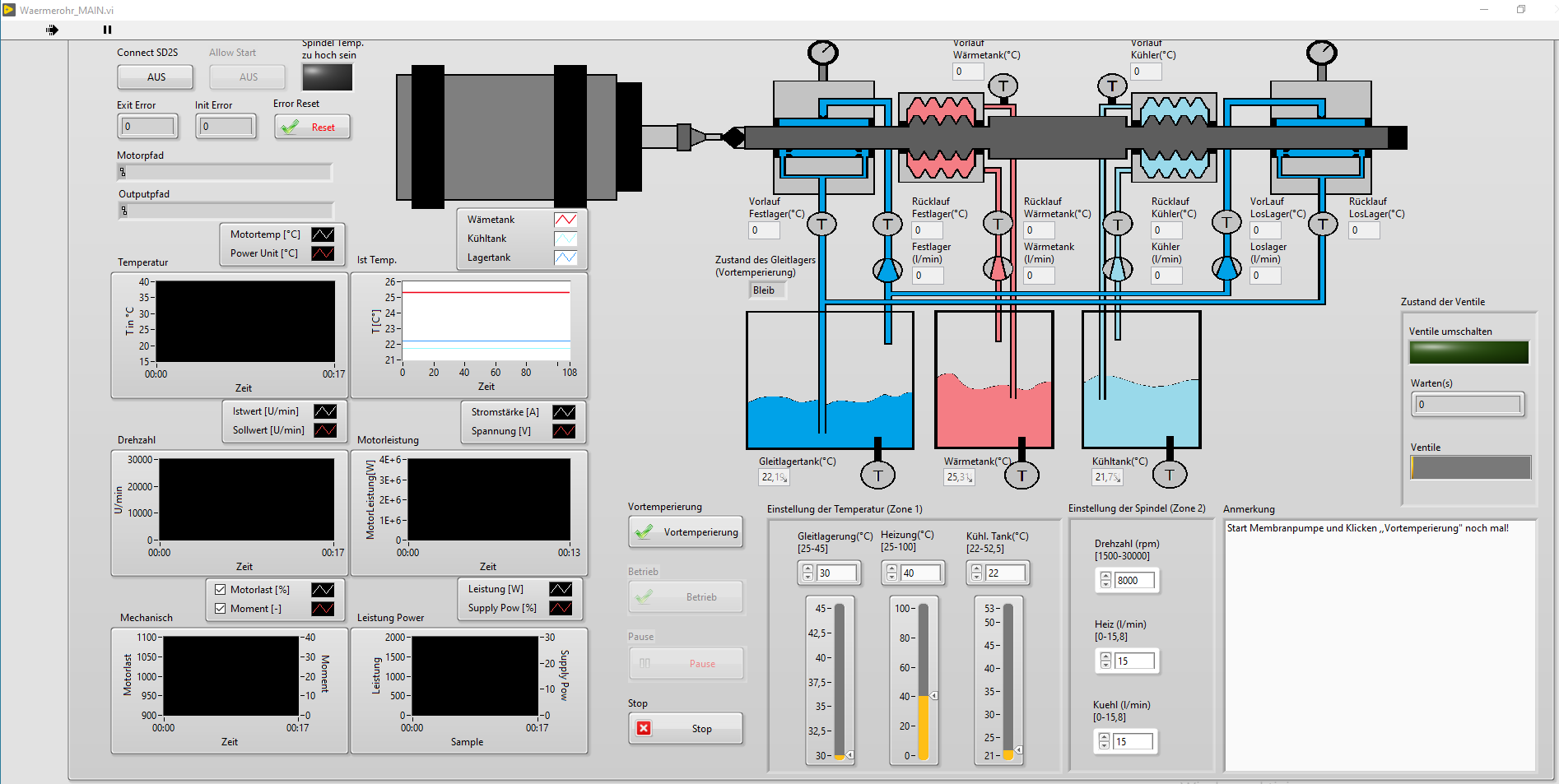

The labs for numerical und experimental works

The labs for numerical und experimental works