Application examples of adaptronic technologies in the field of production engineering

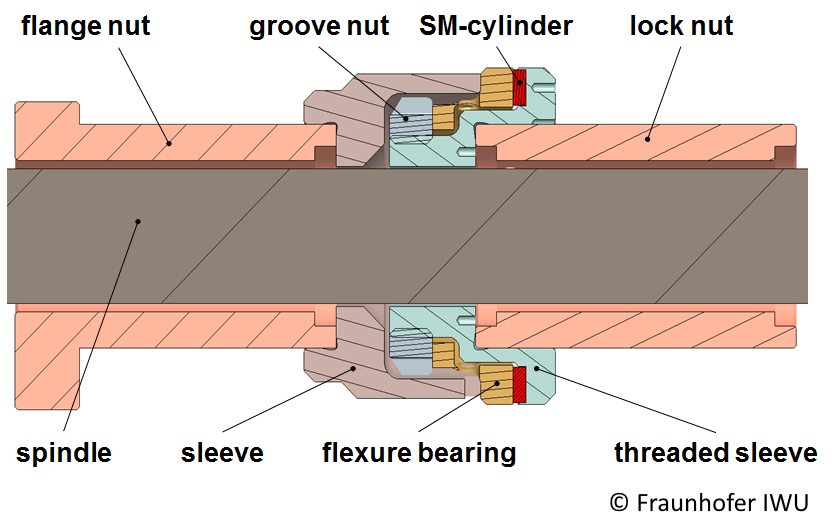

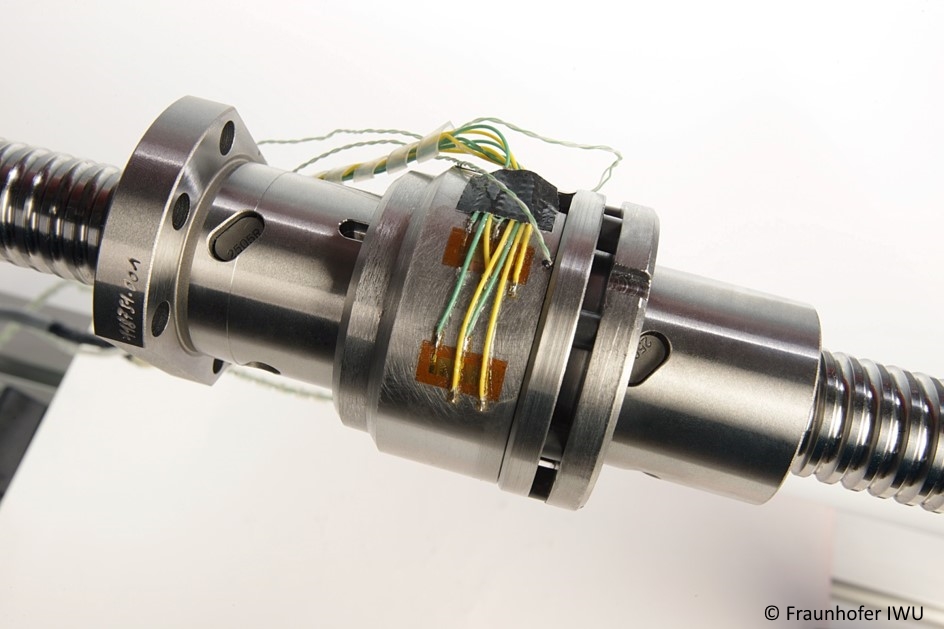

Adaptive ball screw with structure integrated shape memory actuator (thermal SMA) for the prestressed control in the recirculating ball nut

During the improvement process of machine tools properties and design of production processes the aspects of resource efficiency should be considered. However, achieving improvements in the conventional way is always more difficult since it reaches the limits of the existing machine tool systems.

The usage of adaptronic components offers great potential. The integration of these components into the power flow, allows significant increase in dynamics and accuracy of existing machine tools, through the development of redundant additional axis. Furthermore, the corresponding systems offer the possibility to determine the system state and to compensate occurring disturbances.

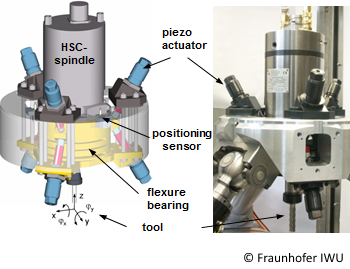

One possible approach for function extension of machine tools, is the use of an adaptive spindle holder. For this purpose, a hexapod kinematics based on piezoelectric stack actuators was developed, where a conventional HSC motor spindle is used. Paired actuator assembly and storage in a universal joint allows the movement of the motor spindle in five degrees of freedom. The working space of the additional kinematics, results from the strokes and working angle of the piezoelectric actuators:

x, y = ±50 μm

z= ±61 μm

φx, φy = 0,6 mrad

Using the adaptive spindle holder the actual machining process can be superimposed, with highly dynamic movements in micrometer range. Integrated into existing machine tool system, it provides new manufacturing possibilities and improves the efficiency of existing processes, thus, the vibrations can be eliminated or in contrary – applied for the specific machining purposes. Thanks to that complex freeform drill holes can be made or thermal machine wear can be decreased.

Adaptive spindle holder for high-precision positioning of the HSC-spindle

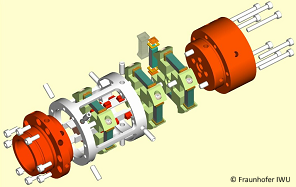

Prototype of the actuator-sensor-unit with piezo stack actuators for torsion compensation in parallel kinematic machine structures