Project Information

DFG-SCHU 1484/27-3 – CVD diamond on steel

| Research Grants | |

| Title of the project: | Reduction of residual stresses in CVD diamond layers on steel parts through creation of hierarchically structured surface topographies by applying cutting processes (2nd period) |

| Duration: | 01/2022–12/2023 |

| Project executing organisation: | Deutsche Forschungsgemeinschaft (German Research Foundation) |

| Head of the subproject: | Prof. Dr.-Ing. Andreas Schubert |

| Staff: | Dipl.-Ing. Richard Börner |

| Project partner: | Chair of Materials Science and Engineering for Metals (FAU Erlangen-Nürnberg) |

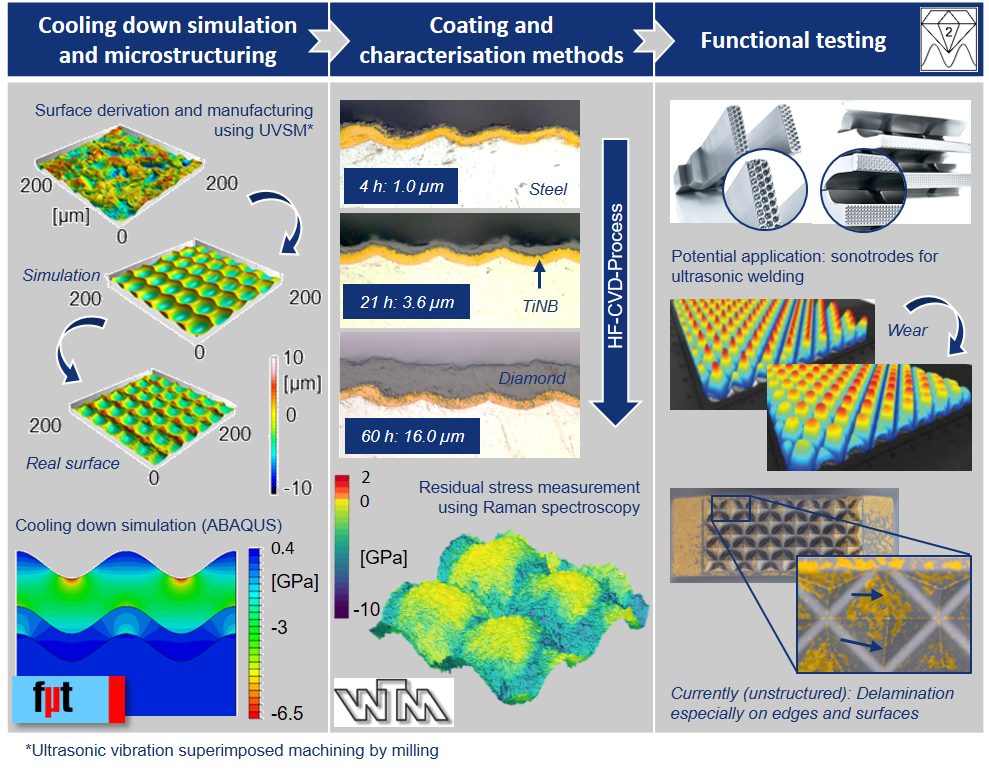

| Abstract: | The application of CVD diamond coatings on steel materials enables various improvements of the performance, such as a reduction of friction and wear in tribomechanically highly loaded systems or a decrease of the adhesion tendency of functional surfaces in thermomechanical applications. The different coefficients of thermal expansion of steel and diamond result in strong residual compressive stresses in the diamond layer during and after cooling down from the coating temperature to room temperature. Consequently, CVD diamond coatings were limited to a very small thickness, since thicker layers tend to flake off. FE analyses of the cooling characteristics of the diamond coated steel substrate and residual stress measurements by RAMAN spectroscopy of the deposited CVD diamond layers on substrates of the steel X46Cr13 contributed to an enhanced understanding of the adhesion mechanisms. It could be determined that a predefined substrate surface microstructure generated by ultrasonic vibration superimposed face milling significantly influences the distribution of the layer-inherent residual stresses. Combined with the TiNB intermediate layer, a tailored interface was realised. This enabled the application of a closed and homogeneous as well as adherent CVD diamond layer with a thickness of up to 16 µm. The relatively good adhesion strength of the diamond layers is mainly attributed to a reduction of the cooling residual stresses due to the significant steel volume increase during the austenite-bainite transformation at temperatures below 400 °C. Based on the results of the first periode, the functional properties of CVD diamond coated specimens with a higher thermal mass and comprising of a "less favourably (higher bainite starting temperature) transforming” steel (X40CrMoV5-1) resulting in stronger cooling residual stresses is investigated. This will broaden the basic understanding of the adhesion mechanisms as well as the potential applications, since this steel is also of high technical relevance. Due to its special vibrational properties, it can be used, as a sonotrode material, e. g. for ultrasonic welding of aluminium components. |

|

|