Core Competency "Materials and Smart Systems"

Materials provide the hardware basis for new innovative processes and technologies for digital materials, additive manufacturing, digital process twins, energy-efficient mobility, as well as sports and medical technology. Based on this, smart systems are created that make everyday life easier and safer and thus, for example, enable an independent life up to an advanced age. The future-facing aspect of increasingly biologizing materials is also being consistently pursued in this field of competence.

Another focus at Chemnitz University of Technology is on developing materials for batteries and fuel cells for alternative drive concepts. The scientific consideration is carried out over the entire scale, from the nano level, through the micro scale, to the macro level. In order to be able to cover these areas in their entirety, mathematics, the natural sciences, and engineering are working together intensively.

An important element to realize these steps is simulation and modeling. Here, mathematicians at Chemnitz University of Technology develop new methods tailored to the respective material systems. This also creates the basis for design of material twins, which are seen as a central component for the further development of Industry 4.0.

In the field of generative manufacturing, the targeted generation of personalized medical implants based on new materials is of great importance. In addition, the development of new types of high-temperature materials for power engineering, which are also used for the additive manufacturing of components, is a current research field. Furthermore, the provision of environmentally compatible and recyclable lightweight composite materials is also of importance, as these requirements often cannot be met by composite materials currently in use. In addition, future-oriented surface coatings from the nano- to the micro-scale are provided to meet the increasing demand for surface functionalization.

Together with scientific partners from mathematics and computer science, data-scientific concepts, and intelligent algorithms for the processing of sensor data and actuator data are also being developed, since data generated in materials science is also becoming increasingly high-dimensional and complex. This includes machine learning methods, especially supervised and unsupervised deep learning. Real-time audio-, image-, video- and other sensor-data analysis complement process monitoring for quality assurance and quality improvement of resulting products.

Last but not least, the transferability of the developed materials with the corresponding models, suitable processes, and the resulting structures and intelligent systems will be analyzed, evaluated and, if suitable, actively promoted by the participating economists and legal scholars.

The individual scientific abilities and potentials of the different research areas at Chemnitz University of Technology are thus brought together and bundled in this field of competence in a suitable form across faculties and topics. The integrative approach starting with basic research up to the transfer of knowledge and the derivation of innovative products and processes contribute not only to the structural development of the scientific location Chemnitz and to the economic strengthening of the region, but also to national and international attention and recognition.

Thus, the composition of this field of competence with the participating professorships from the diverse yet complementary faculties and disciplines forms an extremely suitable platform for the generation of future-oriented interdisciplinary cooperative research projects in the field of Materials and Smart Systems.

News

-

Forschung

TODOSustainable Living Technology

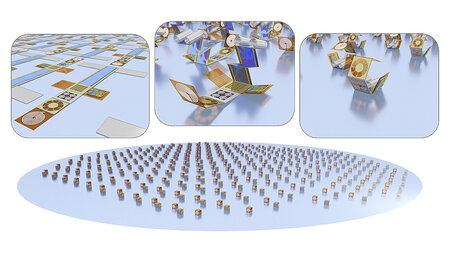

TODOSustainable Living TechnologyIn a recent article in the high-profile journal “Advanced Materials”, researchers in Chemnitz show just how close and necessary the transition to sustainable living technology is, based on the morphogenesis of self-assembling microelectronic modules, strengthening the recent membership of Chemnitz University of Technology with the European Centre for Living Technology (ECLT) in Venice.

-

Forschung

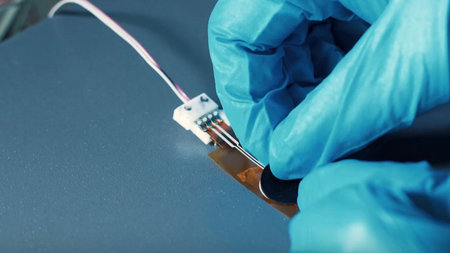

How Nano-Sensors Help with Treatment

How Nano-Sensors Help with TreatmentESF-funded project "SenseCare” at Chemnitz University of Technology successfully completed - Therapeutic support, especially for diabetes mellitus

-

Forschung

It All Depends on Proximity: How Crystal Influences the Resistance of Graphene

It All Depends on Proximity: How Crystal Influences the Resistance of GrapheneA research team, headed by the University of Göttingen but with involvement from Chemnitz University of Technology, observed greater variation than previously assumed – and it was published in Nature Communications

Research Associations

Key Research Areas in the Core Competency "Materials and Smart Systems"

With MAIN, Chemnitz University of Technology will expand its competencies in the field of nanomembrane-based materials, one of the most modern fields in materials science and materials engineering. This will further strengthen Chemnitz University of Technology's core competency in Materials and Smart Systems and contribute to even greater national and international visibility for the university in this field. Further central institution's objectives will be the exploratory research of the fundamental physical and chemical properties as well as the development of the engineering application potential of the material class of flexible nanostructured membranes.

High Entropy Alloys (HEA) are novel alloy systems without a main alloying element. HEA offer extensive research and development potential due to their outstanding material properties. This includes higher wear and corrosion resistance, temperature resistance and resistance against creep. Such alloys have a high technical-economic relevance, for example, for tribologically stressed components at increased operating temperatures. Specific application fields are e.g. highly stressed cylinder running surfaces or surfaces of forming tools. Central matters of the research group are to transfer this new material class of High Entropy Alloys to semi-finished products and components with different coating thickness requirements. This approach serves the purpose of lightweight material construction. A limited use of these cost-intensive complex alloys is the basis for an economical use. The participating professorships from different faculties are also part of the MATIS competence field.

Contact

Speaker of the working group "Materials and Smart Systems":

- Prof. Dr. Guntram Wagner

Phone: +49 371 531-35467

Email: guntram.wagner@…

Deputy speakers:

- Prof. Dr. Dietrich R. T. Zahn

Phone: +49 371 531-33036

Email: zahn@… - Prof. Dr. Martin Stoll

Phone: +49 371 531-33705

Email: martin.stoll@…

Projects (Selection)

FOR 5387 "Printed & Stable Organic Photovoltaics from Non-fullerene Acceptors"

Funding Agency: DFG

Funding Period: 2023-2027

website

ESF Plus Young Researchers Group "Sensor integration and efficient data analysis for hydrogen fuel cells"

Funding Agency: EU/Free State of Saxony/ESF

Funding Period: 2023-2025

CRC 1410 "Hybrid societies: Humans interacting with embodied technologies"

Funding Agency: DFG

Funding Period: 2020-2023

website

"Research of passive radio sensor systems for energy-autonomous shock and vibration monitoring"

Funding Agency: BMBF

Funding Period: 2019-2023

FOR 1713 "Sensorische Mikro- und Nanosysteme"

Funding Agency: DFG

Funding Period: 2011-2019

ERC Starting Grant "Smart dust batteries integrated with near-zero-power surveillance"

Dr. Minshen Zhu

Funding Period: 2022-2027

"Research fab for quantum and neuromorphic computing"

Funding Agency: BMBF (FMD)

Funding Period: 2002-2025

Individual Research Grant "Intelligent Integrated Stent"

Dr. Daniil Karnaushenko; Prof. Dr. Oliver G. Schmidt

Funding Agency: DFG

Funding Period: 2021-2024

ERC Advanced Grant "Medical microbots to support new assisted reproduction techniques"

Prof. Dr. Oliver G. Schmidt

Funding Period: 2019-2024

Leibnitz-Program "Microrobotics, flexible electronics"

Prof. Dr. Oliver G. Schmidt

Funding Agency: DFG

Funding Period: 2018-2025

Cleanroom for Center for Micro- and Nanotechnologies

Funding Agency: EFRE/SAB

Funding Period: 2022-2026

Mittelstand Digital

Funding Agency: BMWK

Funding Period: 2021-2024

Sensorgesteuertes Nährstoffmanagement zur Optimierung von biotechnologisch-agrarischen Produktionssystemen

Funding Agency: SMWK/SAB

Funding Period: 2020-2023

Research Center for Materials, Architectures and Integration of Nanomembranes (MAIN)

Funding Agency: Bund und Länder – FuG

Funding Period: 2013-2019