Overload Robustness

The research field of overload investigations deals with the simulation and measurement of critical operating states of power semiconductors.

In the data sheet of a power semiconductor, nominal operating conditions are noted under which the operation of the semiconductor is guaranteed by the manufacturer, without having to expect a failure of the component. These operating states are described by clear specifications of maximum voltages at the contacts, temperatures, operating points, etc. Abnormal states, which usually arise for the semiconductor in the event of a malfunction in a power electronic circuit, are very critical even for modern semiconductors. Due to the physics of semiconductors, as well as the construction and connection technology, there are concrete limits to the maximum temperature, maximum voltage at the contacts, current intensity, edge steepness etc. which limit the normal operating range. Particularly with regard to the use of new types of semiconductor materials such as SiC or GaN, the question often arises as to whether these materials can maintain or even exceed the high standard of Si components.

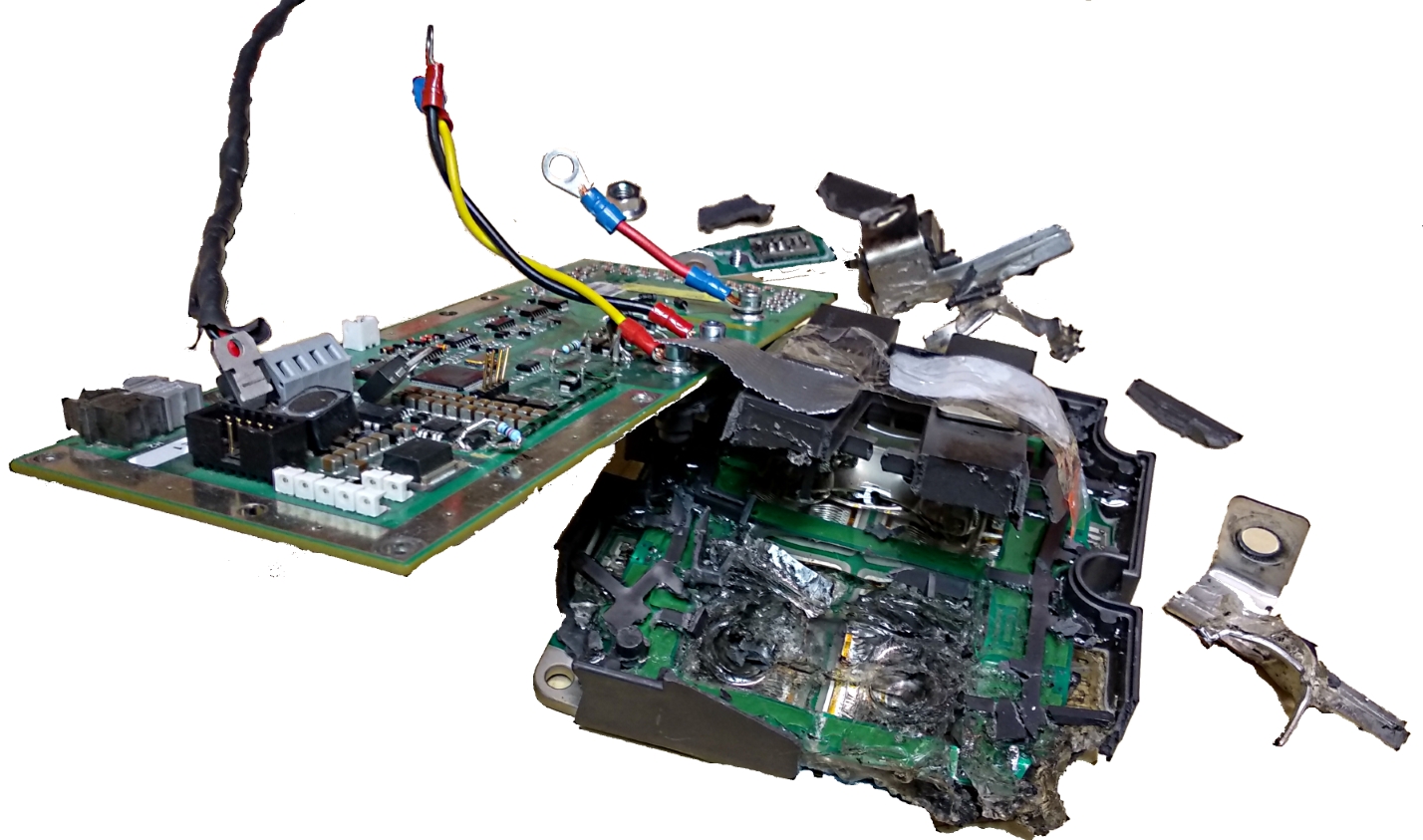

The goal of the investigations is to find weak points in the semiconductor and the packaging and interconnection technology through targeted overloading of the component. The results are used as follows:

|

|

Short Circuit

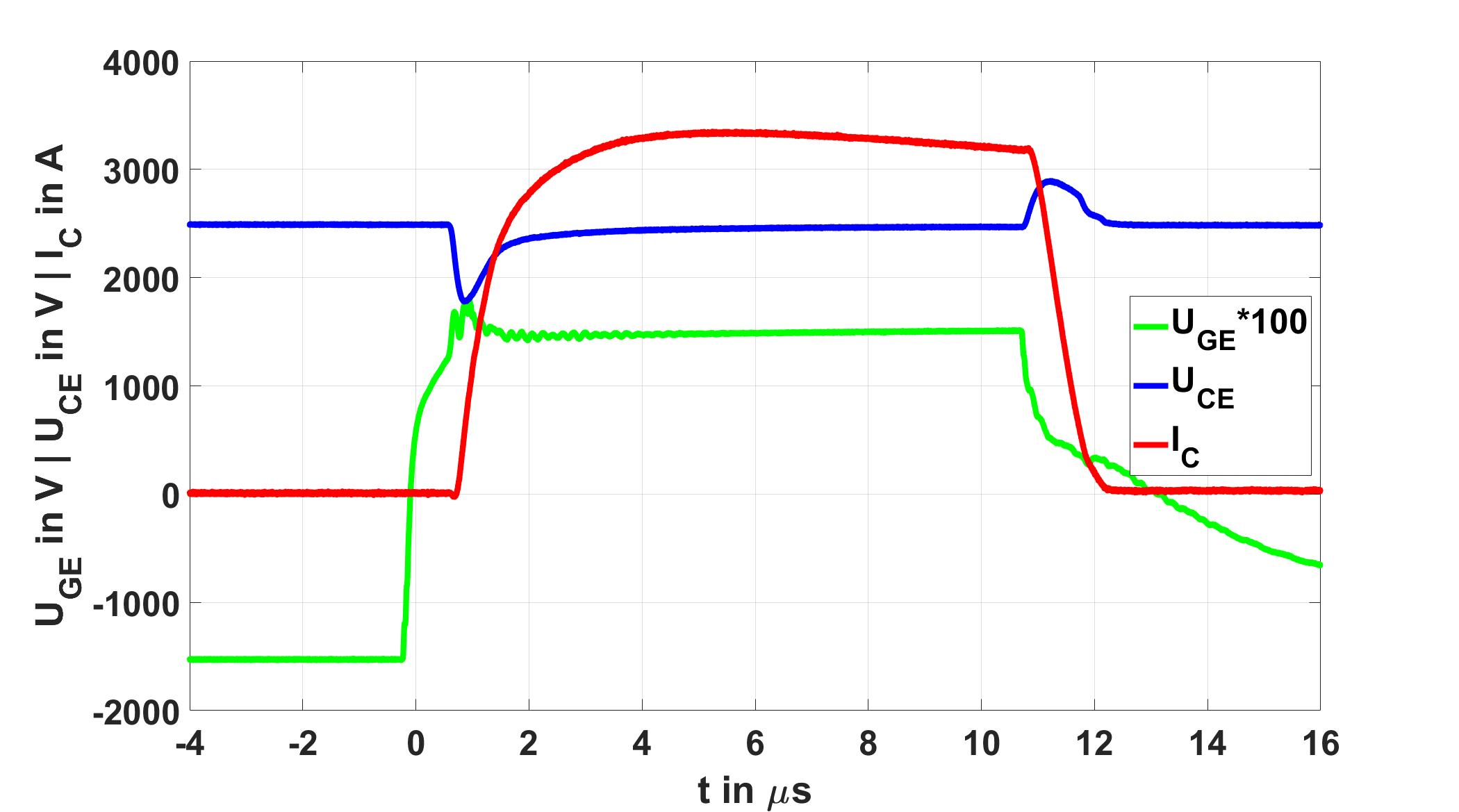

In the short-circuit test, the component is stressed by high voltages and currents in a time range of microseconds. Modern silicon-based power semiconductors ensure robustness at elevated temperatures and specified blocking voltage of about 10μs. In the course of the measurements, different types of short circuit, at different gate voltages, different blocking voltages and driver circuits are investigated.

|

|

Surge Current

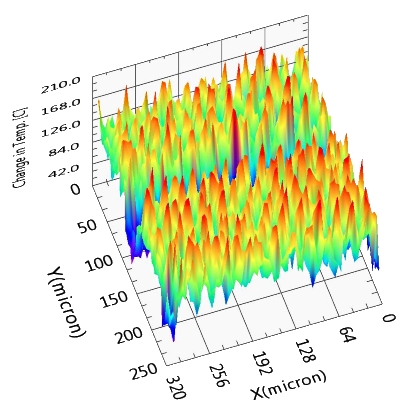

Surge current tests are mostly used for diodes. Depending on the application, however, switchable components such as the IGBT can also benefit from surge current resistance. During the course of the investigation, components are stressed by a semi-sinusoidal current at an assumed mains frequency. In contrast to a short circuit, this results in a significantly longer stress duration and thus different fault patterns or failure mechanisms. The current intensity is gradually increased until the component loses its blocking capability or is thermally destroyed during the pulse.

|

|

Avalanche

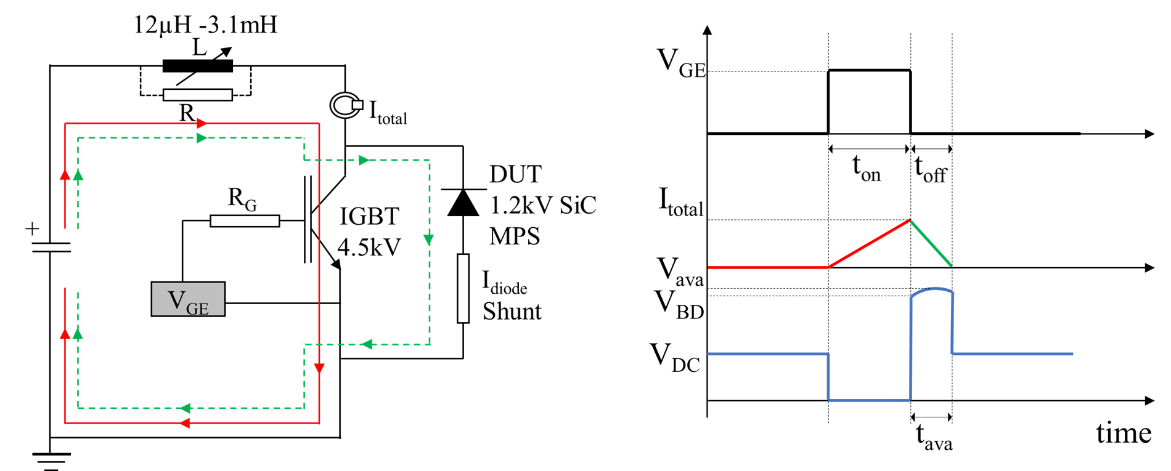

The blocking capability of power semiconductors is limited by the avalanche breakthrough which occurs above the specified blocking voltage. The data sheet only contains information on avalanche robustness, if the component can be exposed to a certain current in this working range without being destroyed. Usually the operation of a component in the avalanche range is investigated with so-called "unclamped inductive switching" (UIS). In contrast to the double pulse test, a drastic voltage increase occurs on the device under test, as the current cannot run free and commutates off abruptly. A careful design of test bench parameters is necessary to bring the component into the avalanche range step by step and to investigate relevant limits.

|

|