Controlled Environment Agriculture (CEA)

In recent years, the ACSD lab has put a large focus of its research onto the fields of Controlled Environment Agriculture and Circular Food Production. But what is a controlled environment and why should my food be circular?

Controlled Environment Agriculture (CEA) has emerged as a vital field within the realm of modern agriculture, offering immense potential to revolutionize food production and address the challenges of feeding a growing global population sustainably. It involves creating optimal growth conditions for plants within closed and highly automated facilities such as greenhouses, vertical farms, or indoor farms, where environmental factors like temperature, light, humidity, and nutrient levels can be monitored and precisely controlled - hence the name.

The importance of CEA lies in its ability to overcome the limitations of traditional farming methods, which are highly dependent on unpredictable weather patterns and susceptible to pest infestations and diseases. By providing a controlled and optimized environment, CEA enables year-round cultivation, reduces water usage significantly, eliminates the need for harmful pesticides, and maximizes crop yields. Moreover, CEA offers the potential for localized and sustainable food production, reducing the reliance on long-distance transportation and minimizing the carbon footprint associated with conventional farming.

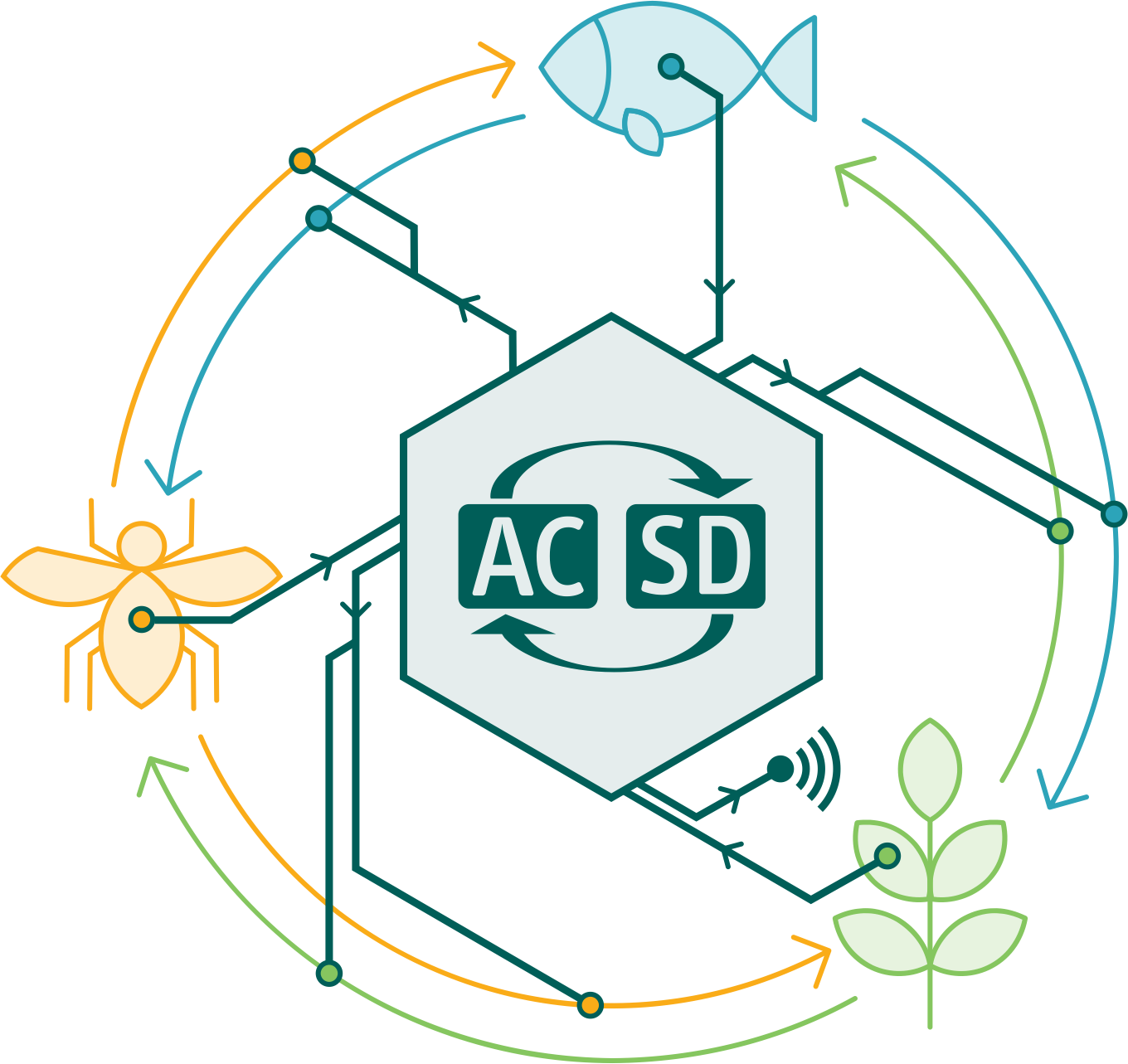

In addition to plant cultivation, we employ our control methods to optimize the growth of larvae and fish, aiming for a circular food production system. Within the CUBES Circle project, we explore the concept of using the byproducts of plant cultivation, such as leftovers and organic waste, as a feed for insect larvae. These larvae, in turn, serve as a nutritious feed source for fish. The fish wastewater, rich in nutrients, is then again recycled as a nutrient solution for the plants, closing the "circle". This closed-loop system minimizes waste, maximizes resource efficiency, and creates a symbiotic relationship between different components of the production system.

To achieve optimal growth of larvae and fish within the circular food production system, feedback control systems are employed at each step of the process, which allow to monitor and regulate crucial parameters such as water quality, temperature, oxygen levels, or feeding schedules. By maintaining precise control over these variables, we ensure that the plants, larvae, and fish receive optimal conditions for growth, health, and nutrient absorption. This integration of feedback control in the circular food production system enhances overall productivity, sustainability, and resource utilization.

Unsurprisingly, building such a circular system requires a deep understanding of the biological processes governing the growth of the involved organisms. Successful implementation and optimization of these systems necessitate collaboration between experts in plant science, aquaculture, biology, environmental science, and engineering disciplines. This interdisciplinary approach enables researchers to not only comprehend the complex physiological and ecological interactions within the system but also develop innovative solutions to enhance growth, optimize nutrient cycling, and maintain the overall health and well-being of the organisms involved. By fostering collaboration across disciplines, this research cultivates a holistic understanding of the interconnectedness of biological processes, technological advancements, and sustainable practices, paving the way for transformative solutions in the food production of the future.

In our Lab we develop methods in collaboration with experts from biology to tackle several challenges within the described setups. Observer design techniques enable estimation of unmeasured variables and help monitor the growth and health of the organisms. Machine learning algorithms are employed to analyze vast amounts of data collected from the system, identifying hidden patterns and trends that enable predictive models and informed decision-making. Using optimal control, we facilitate the efficient allocation of resources, such as light, water, and nutrients, to maximize overall productivity and minimize waste. Additionally, hierarchical control strategies are implemented to manage the complex interactions and dynamics between various components of the system, ensuring coordinated and efficient operation.

Engaging engineers in the study of CEA provides them with a unique opportunity to contribute to sustainable agriculture. Join us in our Lab to explore innovative approaches to optimize plant growth, develop strategies for efficient nutrient (re-)cycling, and design control systems to enhance the growth and well-being of plants, larvae, and fish. This interdisciplinary research fosters a deeper understanding of the interconnectedness of various elements in a circular food production system and equips students with the skills necessary to address the complex challenges of future food production.

Ongoing CEA projects

SensCEA (10/2023-09/2026)

Sensor-based Efficiency Enhancement in Controlled Environment Agriculture The aim of the project is to develop a digital twin for the optimization and automation of cultivation processes for agriculture in controlled environments (greenhouses, vertical farms). The core of the digital twin is a growth model that describes plant growth as a function of the material and energy flows, which are influenced by the energy-intensive climate and light control, among other things. The modeling is intended to deepen the process understanding of the biotechnical greenhouse system so that energy requirements can be reduced. This is to be achieved, for example, by shortening the lighting time with artificial light (LED lighting) through increased CO2 fertilization. In addition, the potential of optimal control algorithms based on model predictions is to be exploited (predictive control). For modeling, data is collected in experiments on GreenResearcher systems from greenhub, the data transfer and the development of a graphical user interface is carried out by mewedo. Grigory Devadze, Jonathan Raecke, Kiran Kumar Sathyanarayanan, and Thomas Göhrt are working on the project.

Sensorgestützte Effizienzsteigerung in Controlled Environment Agriculture Ziel des Vorhabens ist die Entwicklung eines digitalen Zwillings zur Optimierung und Automatisierung von Kultivierungsprozessen für die Landwirtschaft in kontrollierter Umgebung (Gewächshäuser, vertikale Farmen). Kern des digitalen Zwillings ist eine Wachstumsmodellierung, die das Pflanzenwachstum in Abhängigkeit von den Stoff - und Energieströmen beschreibt, die unter anderem von der energieintensive Klima- und Lichtsteuerung beeinflusst werden. Durch die Modellierung soll das Prozessverständnis für das biotechnische System Gewächshaus vertieft werden, sodass der Energiebedarf reduziert werden kann. Dies soll etwa durch eine Verkürzung der Beleuchtungszeit mit künstlichem Licht (LED-Beleuchtung) durch erhöhte CO2-Düngung erreicht werden. Außerdem soll insbesondere das Potential optimaler Reglungsalgorithmen auf Grundlage der Modellvorhersagen genutzt werden (prädikative Regelung). Zur Modellbildung werden Daten in Experimente an GreenResearcher-Systemen von greenhub erhoben, der Datentransfer sowie die Entwicklung eine grafischen Userinterfaces erfolgt durch mewedo. Am Projekt arbeiten Grigory Devadze, Jonathan Raecke, Kiran Kumar Sathyanarayanan und Thomas Göhrt.