Water Sword instead of Laser Sword

Hannover Fair 2018: Professorship for Machine Tools and Forming Technology at Chemnitz University of Technology revolutionizes water jet cutting – university start-up is in the pipeline

-

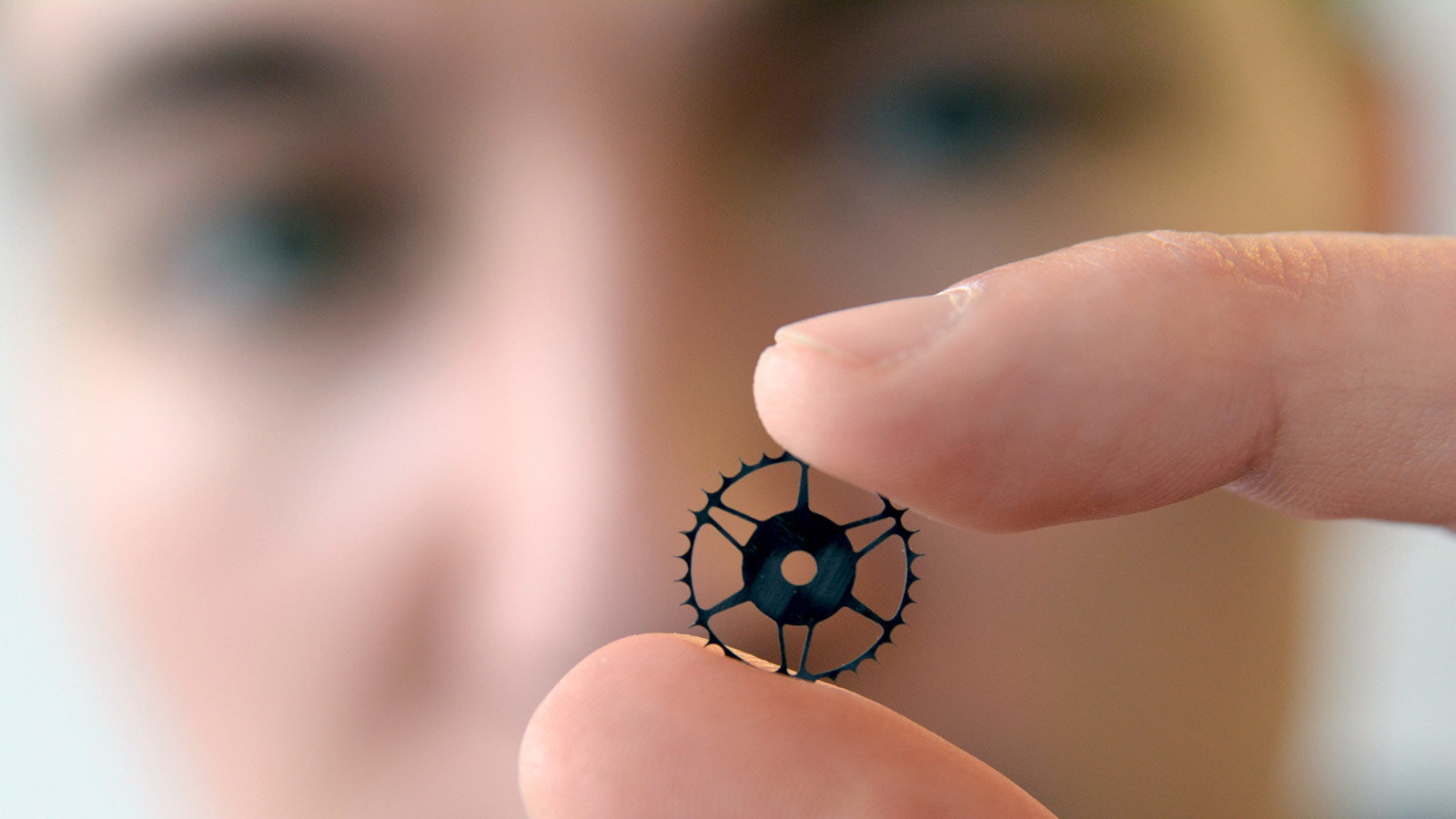

Most filigree parts made of high-performance materials – in this case carbon – can be cut with a novel NC-machining center and a more efficient abrasive water jet. -

Since 2012, Markus Dittrich is dealing with the water abrasive fine jet and wants to establish his own company in 2018.

“Constant dripping wears away the stone” – even the old Greeks knew that 2.000 years ago. Now, scientists of Chemnitz University of Technology proved, that an abrasive water jet can cut super-hard technical ceramics and several meter thick steel with, up to today, unequalled precision and speed.

Since 1990, the water abrasive suspension jet cutting technology is utilized in the oil exploration, the deconstruction of nuclear power plants, and the explosive ordnance disposal. The suspension jet technology is based on the addition of abrasive material prior to the jet generation directly in the high-pressure range.

In order to use this technology in mechanical engineering, where only the more inefficient injection principle is known, the Chemnitz researchers developed a novel NC-machining center with high positioning accuracy and a significant increase in the cutting quality. “The further development of both the suspension jet cutting technology and the machine tool increase efficiency and jet stability and allow a hitherto not feasible processing, such as the cutting of technical ceramics”, explains Martin Dix, head of the division Cutting Technologies at the Professorship for Machine Tools and Forming Technology.

Since 1987, water jet cutting is a research topic at Chemnitz University. Here, the first industrial plant for contract manufacturing was established in 1992. Since then a lot has happened: The Professorship of Machine Tools and Forming Technology networked with leading companies in the sector and improved the cutting performance to the point that this procedure can compete with laser technology in many fields of application. “With the Chemnitz company ATECH, the experts in jet positioning, and the Lübeck ANT AG, experts in suspension systems, we were able to acquire two innovative project partners”, Dix says pleased. “We combined our know-how and can now change the particle flow within the water jet, which means that we can control the amount of particles inside the mixture at any time.”

In the AiF and CfM project “EroJET – Erschließung der Suspensionsstrahltechnologie zur präzisen erosiven Bearbeitung schwer spanbarer Werkstoffe“, the Chemnitz scientists managed to cut –aside from diamond –all kinds of material three times faster than the so far utilized injection jet process, in which the abrasive material is added after the jet generation. The researchers see high potential in the suspension jet technology in particular for the machining of thick fiber compounds, demented carbides, and high performance ceramics, which are installed in catalysts, chemistry plants, heating elements, or coffee machines.

“Our research results show, that a more cost-effective, flexible, and faster production is possible using the novel technology”, explains project leader Markus Dittrich. The promising results will be presented for the first time to the scientific community at the 54th meeting of the Association for Waterjet Cutting technology at Chemnitz University of Technology. Additionally, the subject will be presented at the Hannover Fair, from April 23rd till 27th, at the joint booth “Research for the Future”, Hall 2, booth A38. By now the user feedback is so overwhelming, that Markus Dittrich is currently preparing a university start-up. The start-up network SAXEED at Chemnitz University consults him and supports his enterprise.

Further information are available from Markus Dittrich, phone +49 371 531 32631, email markus.dittrich@mb.tu-chemnitz.de

(Translation: Alissa Hölzel)

Matthias Fejes

14.02.2018