Working on the Perfect Sandwich

Researcher of the Federal Cluster of Excellence MERGE are developing stable lightweight materials made of textile and foam - first applications in headrest and testing car seat

-

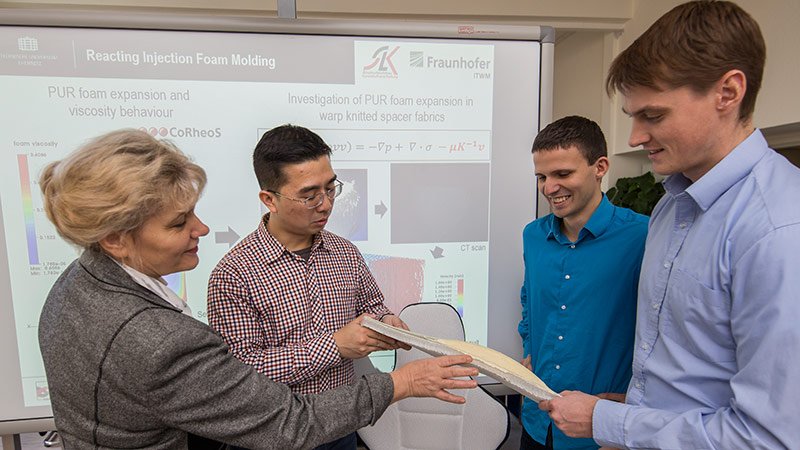

Prof. Dr. Daisy Nestler, Song Ren, Kay Schäfer and Jonas Stiller are currently developing a light, stable, and comfortable car seat after the sandwich principle at the Federal Cluster of Excellence MERGE. Photo: Rico Welzel

It looks like a mixture of witch´s kitchen and chemistry lab:

a container is filling up with foam. It continually rises and rises - and spills. "That is intended", Song Ren illustrates, engineer of the research area "textile/- and plastic-based technologies" (IRD C) at the Federal Cluster of Excellence MERGE. "We analyse the propagation behaviour of different foams. On the basis of those results, we will develop a simulation program which then can be used in the manufacturing of other components with PUR-foam."

The MERGE research area C5, where Ren works, is long-term developing a comfortable and stable car seat of the future working with the "CS-POD" (Car Seat Physiologically Optimised Design) method. The car seat will consist of a hybrid sandwich structure with organic sheets as deck areas and a reinforced 3D warp-knitted foam as core. Apart from being light, solid, and stable the sustainably manufactured compound will be individually adjustable to the demands of the driver.

The key word is "mass customizatio", as the manufacturing is supposed to work with individual parameters and simultaneously in large-scale production. Both requirements are met by this special hybrid compound as it is produced in an injection-mould environment and is intelligently constructed as a lightweight composite. The core is made of 3D warp-knitted textiles – two honeycomb layers that are kept on distance by so called monofilaments (single-thread continuous filaments). Those filaments are aligned vertically between the deck layers. By injecting soft foam in between the deck layers, the filaments are covered, the foam hardens and creates a stable compound.

Currently the team around Song Ren, Kay Schäfer and Jonas Stiller of the MERGE research area C5 is investigating how much of the reaction mass is necessary to fill out a mould completely - without spilling the foam. "For this purpose we measure the viscosity of the foam and the temperature. The virtual expansion is determined by our cooperation partner in this project, the Fraunhofer Institute for Industrial Mathematics", explains Song Ren. "We carry out our investigations with pure foam on the one hand, and with foam in warp-knitted textiles on the other hand to distinguish between differences in the behaviour. We measure the divergences of density in the computer tomograph and bring together all our data in the simulation", the researcher continues. Thus, he and his colleagues can predict the exact amount of foam necessary to fill an individual composite with the required comfort properties. Until this method is reliable, the results will be over and over experimentally validated and verified.

One individual headrest is already finished, a first complete car seat is in testing.

The sandwich seat is supposed to be installed in a demonstrator vehicle in full next year.

The current scientific results have been published inter alia in:

I. E. Ireka, D. Niedziela, K. Schäfer, J. Tröltzsch, K. Steiner, F. Helbig, T. Chinyoka, L. Kroll: Computational modelling of the complex dynamics of chemically blown polyurethane foam. Physics of Fluids 27, 113102 (2015); DOI: 10.1063/1.4935788

http://dx.doi.org/10.1063/1.4935788

K. Schäfer, S. Valentin, B. Meier, I. Roth, F. Helbig: Comparing composites made from hard and soft materials: Increasing the performance of rigid, hard pur foams by incorporating soft, elastic 3D warp-knitted textiles. Kettenwirk-Praxis - Technical Textiles, 2014, 4: 32-35.

V. J. Dura Brisa, F. Helbig, L. Kroll: Numerical characterisation of the mechanical behaviour of a vertical spacer yarn in thick warp knitted spacer fabrics. Journal of Industrial textiles, 2014, 0 (00): 1-17; DOI: 10.1177/1528083714523164.

(Author: Jana Mischke, Translation: Alissa Hölzel)

Mario Steinebach

14.11.2016