Funding in the Millions: DFG Establishes New Research Unit under the Leadership of Chemnitz University of Technology

The German Research Foundation (DFG) has approved the establishment of the research unit "Functional surfaces by high-speed adiabatic processes: microstructure, mechanisms and model development - FUNDAM³ENT" - Spokesman is Prof. Dr. Thomas Lampke, head of the Professorship of Materials and Surface Engineering at Chemnitz University of Technology

-

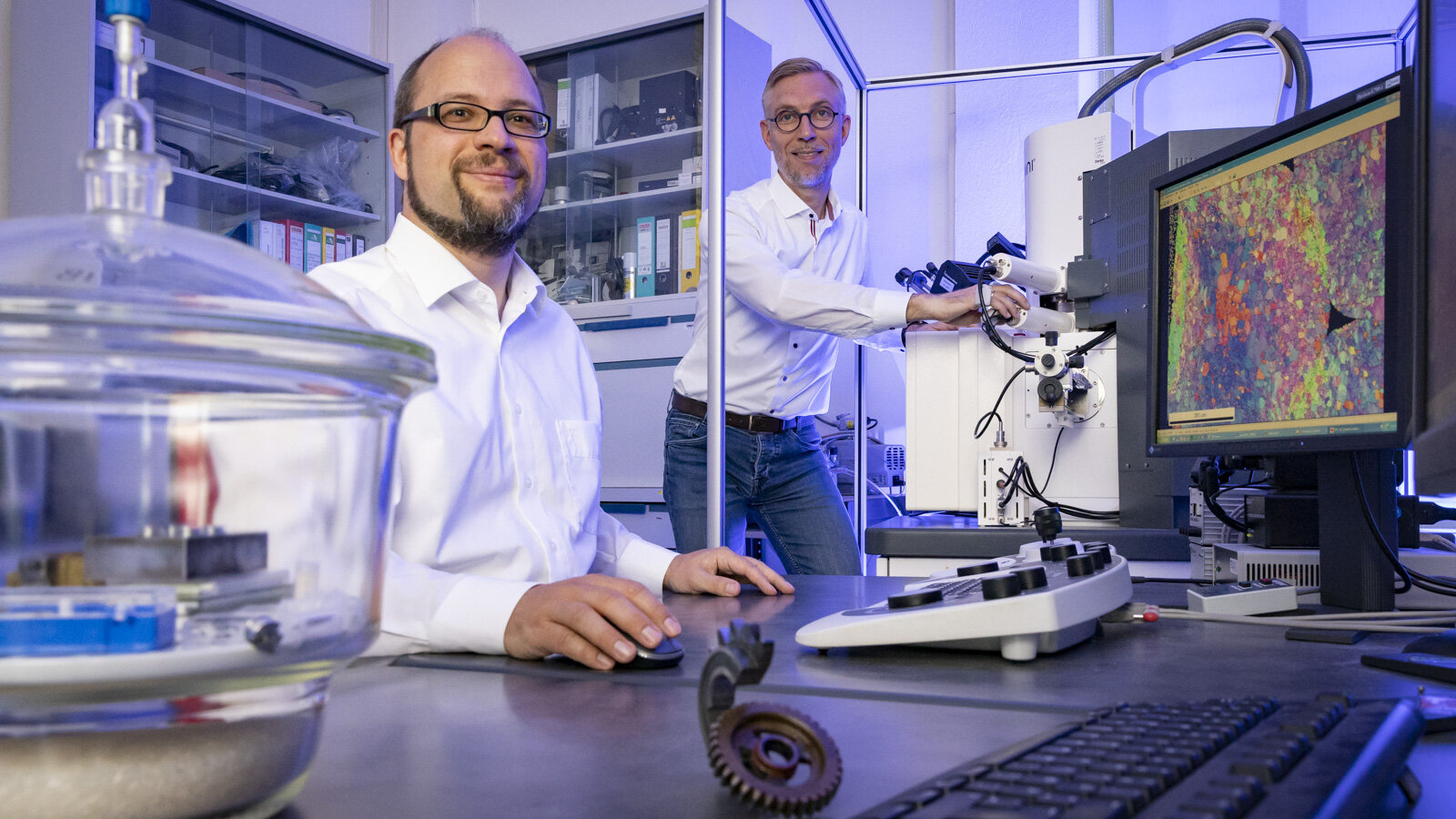

Prof. Dr. Thomas Lampke (right), head of the Professorship of Materials and Surface Engineering and spokesman of the new DFG research unit at Chemnitz University of Technology, and his colleague and co-applicant Dr. Rico Drehmann discuss an experimental result in the scanning electron microscopy laboratory of the Institute of Materials Science and Engineering at Chemnitz University of Technology. In the future, extensive microstructure investigations will be carried out here on the cut surfaces of sheet metal as part of the FUNDAM³ENT research unit. Photo: Jacob Müller -

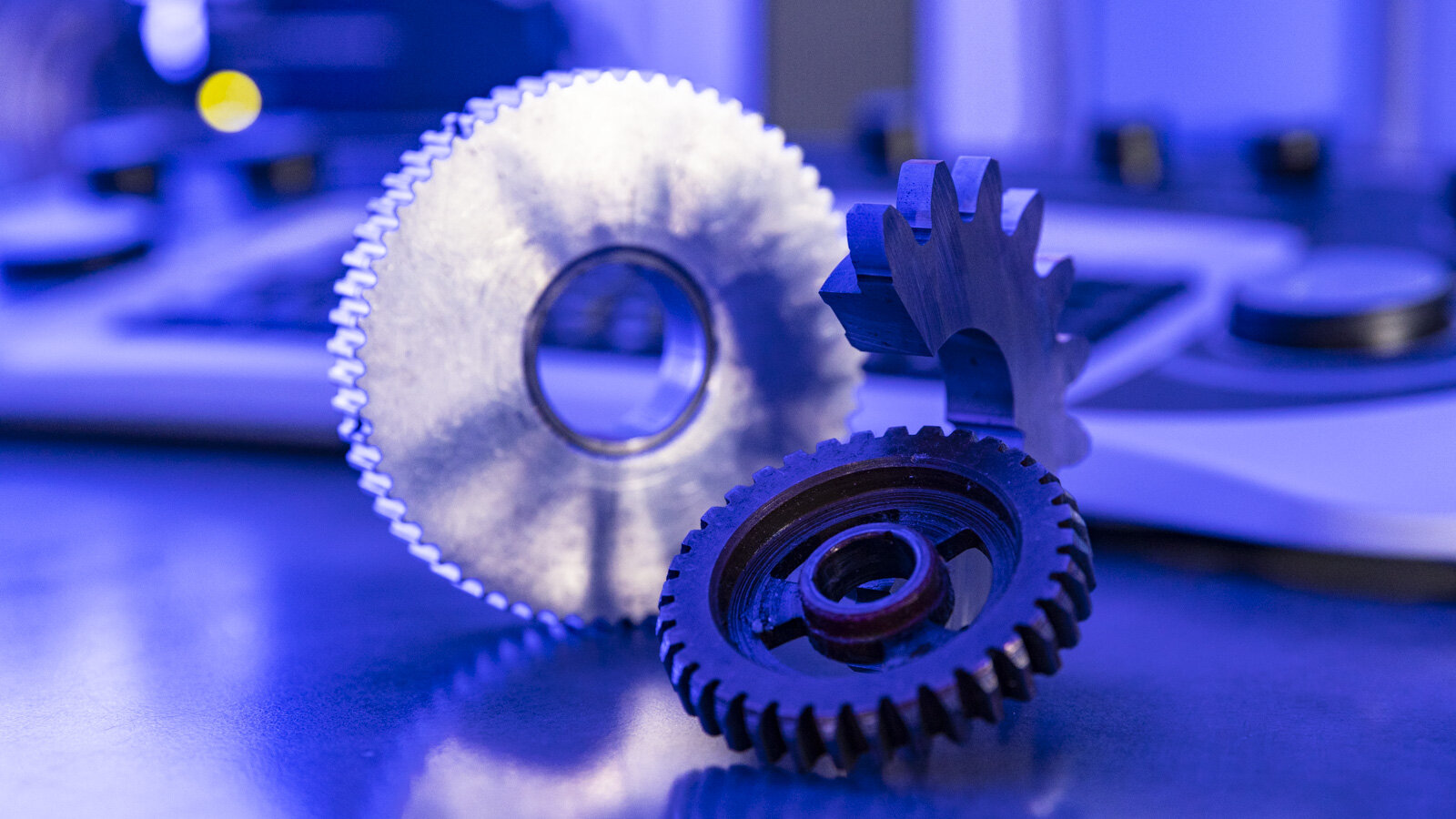

In the future, it should be possible to manufacture components such as gears from various sheet materials by high-speed shearing in a single process step without further post-processing. In addition to high-strength steels, the DFG research unit FUNDAM³ENT is also focusing on light metals such as aluminum. Photo: Jacob Müller

The German Research Foundation (DFG) establishes the new research group "Functional surfaces by adiabatic high-speed processes: microstructure, mechanisms and model development - FUNDAM³ENT" at Chemnitz University of Technology. This was decided by the DFG's Joint Committee on June 28, 2022, on the recommendation of the Senate. According to the statement of the DFG, the research unit will be funded with about 3.72 million euros in the first four-year funding period - of which about 1.54 million euros will go to Chemnitz University of Technology. The spokesperson is Prof. Dr. Thomas Lampke, head of the Professorship of Materials and Surface Engineering at Chemnitz University of Technology.

"I am extremely pleased about the establishment of another DFG research unit at Chemnitz University of Technology within a few months. I would like to congratulate and thank Mr. Lampke and all those involved for this outstanding success. The research unit will contribute significantly to the further strengthening of the core competencies of materials and intelligent systems as well as resource-efficient production and lightweight structures at Chemnitz University of Technology and thus to the reputation of our university in general and the Faculty of Mechanical Engineering in particular," said the President of Chemnitz University of Technology, Prof. Dr. Gerd Strohmeier.

The future research work of the new interdisciplinary DFG research unit will focus on so-called high-speed shear cutting, also known as adiabatic blanking, which is characterized by cutting speeds of greater than 0.8 m/s and represents an efficient alternative for shear cutting of steel and light metals compared to conventional processes from an economic and ecological perspective. The FUNDAM³ENT research unit, which operates between materials science and production engineering, will in future be devoting itself in particular to the question of how various factors influencing materials and processes affect the formation of so-called "adiabatic shear bands" (ASB) in the cut surface of sheet metal during high-speed shear cutting. These shear bands are highly sheared material regions a few micrometers wide that form at high deformation rates, although the exact conditions under which these effects occur have not yet been systematically researched.

"Cut surfaces with ASB have excellent properties such as high hardness, low rollover, low roughness and virtually no burr, and ideally can be used immediately as functional surfaces," Lampke explains. By gaining a materials science-based understanding of shear band development, the mechanical, tribological, and corrosive properties of the cut surface will be targeted. "With the process, we would also be able to save on previously necessary energy-intensive post-processing steps and thus significantly shorten the process chain," says the spokesman for the DFG research unit.

The scientists of the research unit, including numerous young researchers, cooperate in six subprojects. Two of these subprojects are located at Chemnitz University of Technology (Professorship of Materials and Surface Engineering and Professorship of Materials Science). The other subprojects are being worked on at the Fraunhofer Institute for Machine Tools and Forming Technology IWU in Chemnitz, the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg, TU Dortmund University (Institute for Forming Technology and Lightweight Components) and the Technical University of Munich (Chair of Metal Forming and Casting). The close cooperation between the participants, which has already existed for some time, will be further expanded through joint workshops and doctoral seminars in addition to research and publication activities. The research unit places a special focus on the increasingly important topic of research data management. "In this way, the introduction of electronic workflows and the use of electronic lab books in the subprojects will lay the foundation for data sharing and, in perspective, for integration into higher-level national and international data infrastructures such as MaterialDigital or NFDI-MatWerk," says Lampke.

For more information, contact Dr. Rico Drehmann, tel. 0371 531-39331, e-mail rico.drehmann@mb.tu-chemnitz.de, and Prof. Dr. Thomas Lampke, tel. 0371 531-36163, e-mail thomas.lampke@mb.tu-chemnitz.de.

Keyword: DFG Research Units

DFG research units enable scientists to address current and pressing issues in their fields and to establish innovative research directions. Currently, the German Research Foundation funds 174 research units, 14 clinical research units and 16 collegiate research units. In addition to the new research unit "Functional surfaces through adiabatic high-speed processes: microstructure, mechanisms and model development - FUNDAM³ENT", the DFG has established the research unit "Proximity-induced correlation effects in low-dimensional structures" under the leadership of Chemnitz University of Technology in September 2021.

Mario Steinebach

05.07.2022