Our Projects

Projekt (2018-2021)

Partner

- TU Dresden - Professur für Schaltungstechnik und Netzwerktheorie

- Productivity Engineering GmbH, Kesselsdorf

Kontakt

Institute for Print and Media Technology

Email: pminfo@…

Projekt (2021-2024)

Projekt (2021-2024)

Ziel des Vorhabens ist die Entwicklung und realitätsnahe prototypische Erprobung eines innovativen Audio-Fahrgastinformationssystems auf Basis gedruckter Multikanal-Lautsprecherbahnen, einer aus Grundlagenforschung des pmTUC hervorgegangenen Weltneuheit. Im Projekt wird untersucht, inwieweit sich mit diesen Rolle-zu-Rolle  gedruckten Lautsprecherbahnen völlig neuartige Beschallungskonzepte für Schienenfahrzeuge adressieren lassen, z.B. zur besonders homogenen Beschallung langer Korridore in Waggons, aber auch zur individuellen Beschallung von einzelnen Sitzplätzen. Weitere Vorteile können sich in Bezug auf die Fahrzeugkonstruktion ergeben (geringe Bautiefe, niedriges Gewicht, gedruckte Verkabelung, usw.).

gedruckten Lautsprecherbahnen völlig neuartige Beschallungskonzepte für Schienenfahrzeuge adressieren lassen, z.B. zur besonders homogenen Beschallung langer Korridore in Waggons, aber auch zur individuellen Beschallung von einzelnen Sitzplätzen. Weitere Vorteile können sich in Bezug auf die Fahrzeugkonstruktion ergeben (geringe Bautiefe, niedriges Gewicht, gedruckte Verkabelung, usw.).

Partner

- TU Chemnitz, Professur Arbeitswissenschaft und Innovationsmanagement

- Hörmann Vehicle Engineering GmbH

- Seiwo Technik GmbH

Kontakt

Institute for Print and Media Technology

Email: pminfo@…

Projekt (2021-2022)

Das Ziel des Projektes T-PAPER4SOUND ist die Validierung der am pmTUC entwickelten Technologie sowie die Vorbereitung der technischen und wirtschaftlichen Umsetzung. Während der Projektlaufzeit sollen bereits existierende T-PAPER-Demonstratoren zu serienreifen Prototypen entwickelt und zur wirtschaftlichen Verwertung qualifiziert.

Rollengedrucktes Lautsprecherpapier T-PAPER kann verschiedene Sound-Anwendungen integriert werden. Mögliche Einsatzgebiete des Lautsprecherpapiers sind sehr vielfältig. Interaktive Bücher, smarte Verpackungen, Kommunikationsmittel für sehbehinderte Menschen sowie gerichtete Soundanwendungen können mit Lautsprecherpapier T-PAPER realisiert werden.

verschiedene Sound-Anwendungen integriert werden. Mögliche Einsatzgebiete des Lautsprecherpapiers sind sehr vielfältig. Interaktive Bücher, smarte Verpackungen, Kommunikationsmittel für sehbehinderte Menschen sowie gerichtete Soundanwendungen können mit Lautsprecherpapier T-PAPER realisiert werden.

Die Papierlautsprecher werden mittels hocheffizientem und kostengünstigem Rolle-zu-Rolle Verfahren (R2R Verfahren) produziert. Die Basis für die Lautsprecher ist konventionelles Papier, das mit ungiftigen, bleifreien und recyclebaren Polymeren bedruckt wird. Im Vergleich zu konventionellen Lautsprechern, sind die Papierlautsprecher federleicht und flexibel und können, dank hochproduktiven Druckverfahren, schnell in verschiedenen Größen und Formen angefertigt werden.

Kontakt

Institute for Print and Media Technology

Email: pminfo@…

Project (2018-2021)

IMPETUS is developing a pilot line in an industrial environment for manufacturing fully integrated paper-based electrochemical biosensors that directly transfer the measured data to the user’s smartphone. Self-powered disposable test stripes work as lateral flow test with quantitative readout.

This project will evolve new technologies for paper manufacturing, coating and surface modification. Moreover, the special inks will be developed. Cellulose-based inks will be used for manufacturing the printed battery as well as bio-inks for surface functionalization and reagent deposition. To enable electrochemical signal acquisition, storage and contactless NFC transmission a highly integrated and energy efficient silicon microchip will be designed. This microchip will be installed on the paper substrate by an inline placement process. Paper will be applied as substrate for the printed circuits as well as active component of the printed battery and of the biosensor.

The IMPETUS pilot line will combine screen-, flexo- and inkjet printing methods and an unhoused chip placement enabling a seamless roll-to-roll process with high throughput production. The pilot line could be easily adapted for fabrication of other sensing applications (e.g. medical diagnostics, food safety, etc.). It enables cooperation with interested third parties after the project end.

Goal

The IMPETUS pilot line will combine screen-, flexo- and inkjet printing methods and an unhoused chip placement enabling a seamless roll-to-roll process with high throughput production. The pilot line could be easily adapted for fabrication of other sensing applications (e.g. medical diagnostics, food safety, etc.). It allows cooperation with interested third parties after the project end.

Potential applications

- Fast and inexpensive point-of-care device for discrimination between bacterial and viral infections

Partners

- AIT Austrian Institute of Technology GmbH, Austria

- Papiertechnische Stiftung, Germany

- Maurer Services GmbH , Germany

- Pro-Active sprl, Belgium

- Saralon GmbH, Germany

- DPI Holding GmbH, Austria

- Felix Schoeller Holding GmbH & Co KG, Germany

- Infineon Technologies Austria AG, Austria

- Melecs EWS GmbH, Austria

- R-Biopharm AG, Germany

- Ricoh UK Products Ltd, United Kingdom

- Sun Chemical Ltd

Contact

Institute for Print and Media Technology

Email: pminfo@…

Project (2019-2021)

WEARPLEX project enables a multidisciplinary research to combine printed electronics with flexible and wearable textile-based biomedical multi-pad electrodes. The aim of the project is the integration of the printable electronics and manufacturing processes for stretchable textile based multi-pad electrodes with integrated logic circuits. This technology enables to increase a number of electrode pads (channels) and allows the creation of new products for medical purposes and life-style.

WEARPLEX electrodes combined with the advanced printed electronics enables the connection of individual pads in random configurations to the output leads of the electrode. These pads could be arbitrary organized into virtual electrodes and connected to any standard multi-channel recording and stimulation system. Multidisciplinary research team will also develop software methods to enable automatic calibration of these virtual electrodes, to detect stimulation/recording hotspots and adjust the virtual electrodes accordingly.

Goal

The WEARPLEX project will create a new generation of smart electrodes. Wearable and stretchable garment will allow the adaption simultaneously to the user. Also smart electrodes will enable a recording/stimulation scenario using movement type and target muscles. The WEARPLEX will lead to a universal solution compatible with any system.

Potential applications

- Medical devices for the measurement of electrophysiological signals

- Applications for electrical muscle stimulation

Partners

- University of Southhampton, United Kingdom

- Fundacion Tecnalia Research & Innovation, Spain

- Fundacion BCMaterials – Basque Centre for Materials, Applications and Nanostructures, Spain

- Rise Research Institutes of Sweden AB, Sweden

- Aalborg Universitet, Denmark

- Abalonyx AS, Norway

- IDUN Technologies AG, Switzerland

- SCREENTEC Oy, Finland

- Tecnalia Serbia Doo Beograd, Serbia

Contact

Institute for Print and Media Technology

Email: pminfo@…

Project (2019-2021)

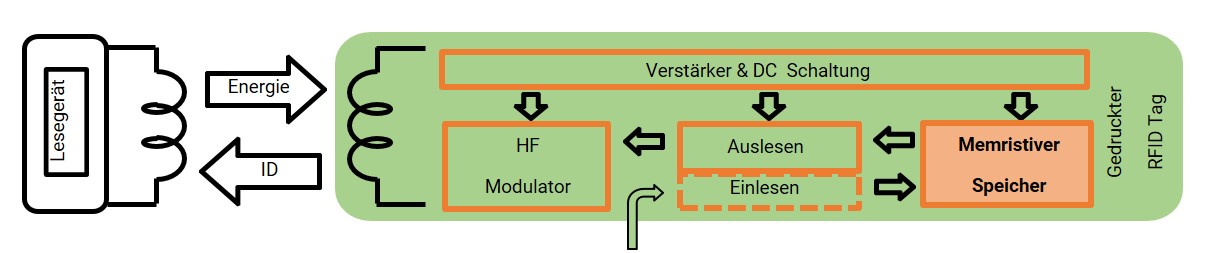

To provide an excellent research, PAPERONICS brings together research institutions and companies active in the areas of paper, labels, ink and printing technology, cardboard, sensors, RFID tags, scavenger and encapsulation technology, software applications and end users of smart packaging.

Printed sensors for temperature and humidity, light emission, as well as touch monitor provide intelligent packaging functionality with user interaction. Printed organic solar cells on paper provide energy to printed batteries and supercapacitors.

The project PAPERONICS will demonstrate 3 application scenarios such as a customer relationship product, a temperature logger and an anti-counterfeiting tag. Temperature stable, stiff and printable paper substrate is suitable for efficient roll-to-roll printing process. The other goal is the development of encapsulation materials protecting sensitive electronic components such as solar cells, printed wires, antennas, OLEDs. New materials will allow encapsulation in air, instead of in nitrogen/argon glove boxes at lower cost.

Goal

PAPERONICS aims to develop low-cost sensor systems on paper-based substrates to create smart packaging. The combination of low cost technologies such as sensors, RFIDs and solar cells printed on paper can give companies a possibility for innovation of their products or creation of new products and exploring of new markets.

Potential applications

- Low cost multisensory paper and packaging applications

Partners

- Universiteit Hasselt, Belgium

- IMEC vzw, Smart Electronics, Belgium

- KU Leuven, Advanced Manufacturing Laboratory, Belgium

- Fraunhofer-Institut für Verfahrenstechnik und Verpackung, Germany

- Papiertechnische Stiftung – Institut für Zellstoff und Papier, Germany

Contact

Institute for Print and Media Technology

Email: pminfo@…

Project (2017-2020)

pmTUC has developed a technology which allows the manufacturing of loudspeakers solely by means of conventional mass printing technologies on flexible substrates like foil or even paper. More precisely, we are talking about printed piezoelectric loudspeakers, i.e. a piezoelectric crystal transfers an applied AC voltage to a mechanical deformation and a vibration of the whole substrate. If the frequency of the AC signal is in the frequency range of 20 Hz to 20 kHz, audible sound is generated. In our case a piezoelectric polymer is sandwiched between two organic electrodes, i.e. we have truly fully plastic speakers without magnets. All layers can be printed step by step on a substrate but thanks to new developments during the last three years, we are now able to integrate all electronic layers within a special paper – the tone paper – or shorter T-paper – was born making it possible to print on both sides of the paper color pictures or whatever you are used to print (or write) on paper. The printed electronics part keeps hidden and invisible. At the starting point of this project, the realisation of the T-paper is based on a semi-automatic sheetfed process with low efficiency and throughput. However, first applications could be successfully demonstrated like the T-book in 2015 – a unique photo book with speaking images.

Now, main aim of the VIP+ project T-paper is to transfer the inefficient sheetfed manufacturing to a high-throughput roll-to-roll pilot line at one of pmTUC’s R2R printing presses. This includes the development and validation of a stable R2R printing process of all functional layers, the inline polarisation of the piezoelectric material but also post-press technologies like lamination and folding.

Goal

- Roll to roll manufacturing of piezoelectric loudspeaker paper

- Validation of the manufacturing process

- Demonstration of different T-PAPER prototypes

Prototypes available

- T-BOOK 2 with fully integrated loudspeaker pages into a hardcover book including power supply with rechargeable batteries as well as sensors detecting open pages

- T-RING – a surround-sound installation with seven 100V ELA-amplifiers and color print (4 m loudspeaker web)

- T-POSTER in SRA3 size with or without pressure sensor

- T-WEB – a paper based loudspeaker web for homogenous sound along of 4 m length

Contact

Institute for Print and Media Technology

Email: pminfo@…

Project (2018-2020)

Printexray project aims to create a novel pressure sensor on textile. The textile based nanocomposite sensors have advantages for many applications, especially for medical purposes or wearables thanks to their high flexibility, bend fracture resistance, costs efficiency and at the same time high sensitivity. The sensors are manufactured by polymeric CNTs dispersion applied on textile substrate using screen printing.

Because of using printing technologies the sensor size is scalable and the manufacturing is cost efficient. The printing method allows to produce sensors for large area applications.

Due to the novel weaving and stitching methods the electrical conductive yarns stay highly flexible and resistant to bend fracture. It allows a more sustainable use of sensors in the future potential applications. Stitched conductive yarns are more robust during the cleaning and provide longevity to the future applications.

Potential applications

- Sensing mattresses for clinics and homecare

- Medical and technical (smart) clothing

- Industrial and automotive applications

- Building automation for energy consumption optimization

Partners

- Professur für Mess- und Sensortechnik, TU Chemnitz, Germany

- Textilforschungsinstitut Thüringen-Vogtland e.V. – TITV Greiz, Germany

Contact

Institute for Print and Media Technology

Email: pminfo@…

Project (2017-2020)

SPS3D Project develops adaptive measurement sensor technology for spectral surface inspection in 3D objects. The inspection of spectral properties of surfaces (spectral colour measurement technology) will become an important step in almost all production areas. To provide an excellent research, SPS3D brings together Institute for Print and Media Technology and companies active in the areas of sensor technology, photonics, ink manufacturing and industrial inspection.

The new sensor concept is based on a CMOS-based 12-line sensor which is capable of recording 12-channel pixel-by-pixel image data. The three-dimensional image data is created by dividing the rows into a left and right field of view. After that a stereoscopic procedures can be used. Such a sensor will be provided with application-specific filter functions. As a result a hybrid three-dimensional / spectral sensor will be created.

Goal

The project aims to develop a new generation of measurement sensors. Each of 15,000 pixels of a sensor will be equipped with an application-specific filter in order to achieve any spectral sensitivity. The new sensor technology will allow spectral colour measurements on three-dimensional surfaces in industrial applications with significantly reduced colour measurement errors and high inspection speed.

Potential applications

- 3D/spectral sensor measurment system for industrial inspections

Partners

- Chromasens GmbH, Germany

- ficonTEC Service GmbH, Germany

- Innovative Ink GmbH, Germany

- Baumer Inspection GmbH, Germany

Contact

Institute for Print and Media Technology

Email: pminfo@…