Our Projects

Projekt

Partner

- TU Dresden - Professur für Schaltungstechnik und Netzwerktheorie

- Productivity Engineering GmbH, Kesselsdorf

Kontakt

Institute for Print and Media Technology

Email: pminfo@…

Project

IMPETUS is developing a pilot line in an industrial environment for manufacturing fully integrated paper-based electrochemical biosensors that directly transfer the measured data to the user’s smartphone. Self-powered disposable test stripes work as lateral flow test with quantitative readout.

This project will evolve new technologies for paper manufacturing, coating and surface modification. Moreover, the special inks will be developed. Cellulose-based inks will be used for manufacturing the printed battery as well as bio-inks for surface functionalization and reagent deposition. To enable electrochemical signal acquisition, storage and contactless NFC transmission a highly integrated and energy efficient silicon microchip will be designed. This microchip will be installed on the paper substrate by an inline placement process. Paper will be applied as substrate for the printed circuits as well as active component of the printed battery and of the biosensor.

The IMPETUS pilot line will combine screen-, flexo- and inkjet printing methods and an unhoused chip placement enabling a seamless roll-to-roll process with high throughput production. The pilot line could be easily adapted for fabrication of other sensing applications (e.g. medical diagnostics, food safety, etc.). It enables cooperation with interested third parties after the project end.

Goal

The IMPETUS pilot line will combine screen-, flexo- and inkjet printing methods and an unhoused chip placement enabling a seamless roll-to-roll process with high throughput production. The pilot line could be easily adapted for fabrication of other sensing applications (e.g. medical diagnostics, food safety, etc.). It allows cooperation with interested third parties after the project end.

Potential applications

- Fast and inexpensive point-of-care device for discrimination between bacterial and viral infections

Partners

- AIT Austrian Institute of Technology GmbH, Austria

- Papiertechnische Stiftung, Germany

- Maurer Services GmbH , Germany

- Pro-Active sprl, Belgium

- Saralon GmbH, Germany

- DPI Holding GmbH, Austria

- Felix Schoeller Holding GmbH & Co KG, Germany

- Infineon Technologies Austria AG, Austria

- Melecs EWS GmbH, Austria

- R-Biopharm AG, Germany

- Ricoh UK Products Ltd, United Kingdom

- Sun Chemical Ltd

Contact

Institute for Print and Media Technology

Email: pminfo@…

Project

WEARPLEX project enables a multidisciplinary research to combine printed electronics with flexible and wearable textile-based biomedical multi-pad electrodes. The aim of the project is the integration of the printable electronics and manufacturing processes for stretchable textile based multi-pad electrodes with integrated logic circuits. This technology enables to increase a number of electrode pads (channels) and allows the creation of new products for medical purposes and life-style.

WEARPLEX electrodes combined with the advanced printed electronics enables the connection of individual pads in random configurations to the output leads of the electrode. These pads could be arbitrary organized into virtual electrodes and connected to any standard multi-channel recording and stimulation system. Multidisciplinary research team will also develop software methods to enable automatic calibration of these virtual electrodes, to detect stimulation/recording hotspots and adjust the virtual electrodes accordingly.

Goal

The WEARPLEX project will create a new generation of smart electrodes. Wearable and stretchable garment will allow the adaption simultaneously to the user. Also smart electrodes will enable a recording/stimulation scenario using movement type and target muscles. The WEARPLEX will lead to a universal solution compatible with any system.

Potential applications

- Medical devices for the measurement of electrophysiological signals

- Applications for electrical muscle stimulation

Partners

- University of Southhampton, United Kingdom

- Fundacion Tecnalia Research & Innovation, Spain

- Fundacion BCMaterials – Basque Centre for Materials, Applications and Nanostructures, Spain

- Rise Research Institutes of Sweden AB, Sweden

- Aalborg Universitet, Denmark

- Abalonyx AS, Norway

- IDUN Technologies AG, Switzerland

- SCREENTEC Oy, Finland

- Tecnalia Serbia Doo Beograd, Serbia

Contact

Institute for Print and Media Technology

Email: pminfo@…

Project

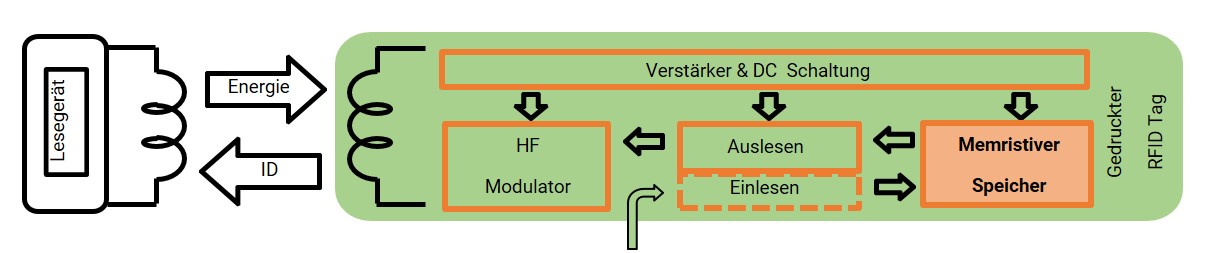

To provide an excellent research, PAPERONICS brings together research institutions and companies active in the areas of paper, labels, ink and printing technology, cardboard, sensors, RFID tags, scavenger and encapsulation technology, software applications and end users of smart packaging.

Printed sensors for temperature and humidity, light emission, as well as touch monitor provide intelligent packaging functionality with user interaction. Printed organic solar cells on paper provide energy to printed batteries and supercapacitors.

The project PAPERONICS will demonstrate 3 application scenarios such as a customer relationship product, a temperature logger and an anti-counterfeiting tag. Temperature stable, stiff and printable paper substrate is suitable for efficient roll-to-roll printing process. The other goal is the development of encapsulation materials protecting sensitive electronic components such as solar cells, printed wires, antennas, OLEDs. New materials will allow encapsulation in air, instead of in nitrogen/argon glove boxes at lower cost.

Goal

PAPERONICS aims to develop low-cost sensor systems on paper-based substrates to create smart packaging. The combination of low cost technologies such as sensors, RFIDs and solar cells printed on paper can give companies a possibility for innovation of their products or creation of new products and exploring of new markets.

Potential applications

- Low cost multisensory paper and packaging applications

Partners

- Universiteit Hasselt, Belgium

- IMEC vzw, Smart Electronics, Belgium

- KU Leuven, Advanced Manufacturing Laboratory, Belgium

- Fraunhofer-Institut für Verfahrenstechnik und Verpackung, Germany

- Papiertechnische Stiftung – Institut für Zellstoff und Papier, Germany

Contact

Institute for Print and Media Technology

Email: pminfo@…