Life Cycle Analysis and Recycling of Plastic Conveyor Chains

Project Goal

Development of a procedure (PCR) to create an environmental label (EPD) for tribologically stressed plastic components such as sliding chains, slide rails, belts, bearings, transmission gears and drive elements.

Motivation

As a cause of climate change, the greenhouse effect generated by human activities is now recognized worldwide. So far, it has led to a global average temperature increase of 0.8–1.2 °C in the time period 1880 to 2012 [1]. At present, the CO2 concentration is growing by 3 ppm per year, 200 times faster than at the end of the last ice age. In order to counteract this trend, the economy and industry must be reorganized in the long term according to ecological criteria. In order to achieve full decarbonisation, CO2 emissions from all sources (fossil fuel burning, industry, agriculture) must be reduced to zero by 2100 at the latest [2]. This includes, in particular, the efficient and sustainable use of raw materials and resources. In order to take this aspect into account, so-called environmental declarations have become established for many products or processes to enable a comparability of CO2 emissions [3].

Focus

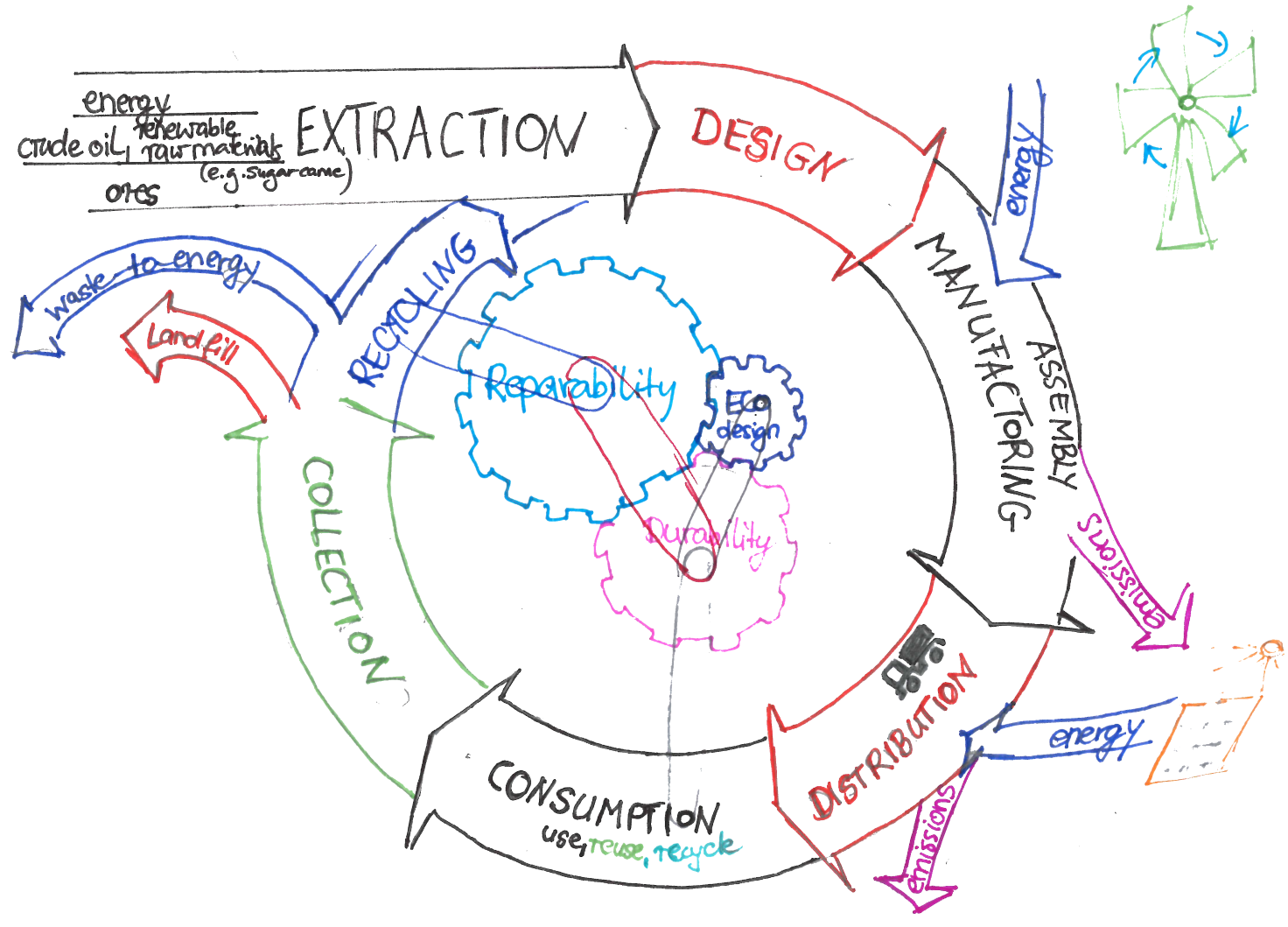

Environmental emissions are generated in all phases of a products life. The main phases of a life cycle are production, use and disposal/recycling. Ideally it is a closed circuit, i.e. all waste materials are resupplied to the production. This research project concentrates on two main topics:

- Use phase: How do theoretically implemented actions for increasing energy efficiency, e.g. by lightweight construction or reduction of friction, lead to an improvement in the environmental balance in practice?

- End-of-Life phase: Which measures to close the product life cycle lead to an improvement of the environmental balance?

Participation

The standardized creation of an EPD (z. B. DIN ISO 14025, 14040 as well as 14044) requires the cooperation of system manufacturers and market participants to determine real loads, usage cycles and energy consumption data. The required data should be determined in discussions as well as load analyzes and measurements in systems. In the end, their applicability is examined. Ideally, companies are involved in creating the PCR as part of the PCR Committee.

Benefit

On the basis of the created PCR, EPDs can be published to clarify the environmental friendliness of products and can be be used for environmental marketing.

For selecting building materials (such as windows), EPDs became common for evaluating products in Germany [4]. The usage in other industry sectors is growing, e.g. for elevators first EPDs have been published at environdec [5].

Costs

The participation in the PCR comitee is for free.

Contact

Dipl.-Wirt.-Ing. Lynn Lüdemann

Tel.: +49 371 531-37144

lynn.luedemann@mb.tu-chemnitz.de

Dr.-Ing. Jens Sumpf

Tel.: +49 371 531-32853

jens.sumpf@mb.tu-chemnitz.de

Project Funding

Support by

Downloads

References

- Intergovernmental Panel on Climate Change (IPCC) (Ed.): Global Warming of 1.5 °C. October 2018. PDF

- Umweltbundesamt (Ed.): Developing criteria to align investments with 2 C-compatible pathways – Final Report. In: Climate Change, 12/2017. Dessau-Roßlau, April 2017. ISSN 1862-4359. PDF

- The International EPD® System: What is an EPD?. URL: https://www.environdec.com/What-is-an-EPD/. Visited: 07.11.2018.

- Institut Bauen und Umwelt e.V.: Veröffentlichte EPDs. URL: https://ibu-epd.com/veroeffentlichte-epds/. Visited: 07.11.2018.

- The International EPD® System: thyssenkrupp Elevator publish first EPD of a lift in the International EPD® System. URL: https://www.environdec.com/News-archive/thyssenkrupp-Elevator-publish-first-EPD-of-a-lift/. Visited: 07.11.2018.