News

Merry Christmas and a Happy New Year to you all!

Dear students, friends, colleagues and project partners,

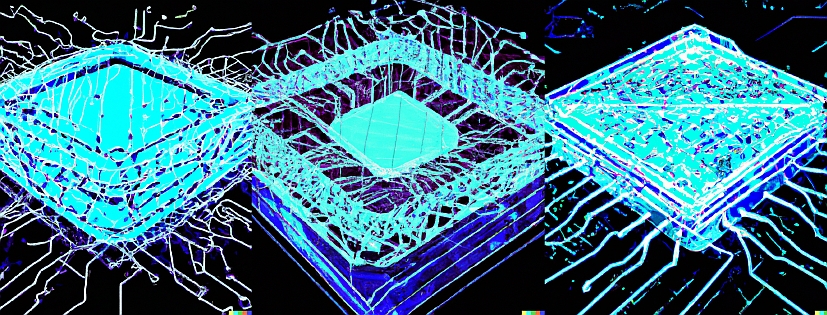

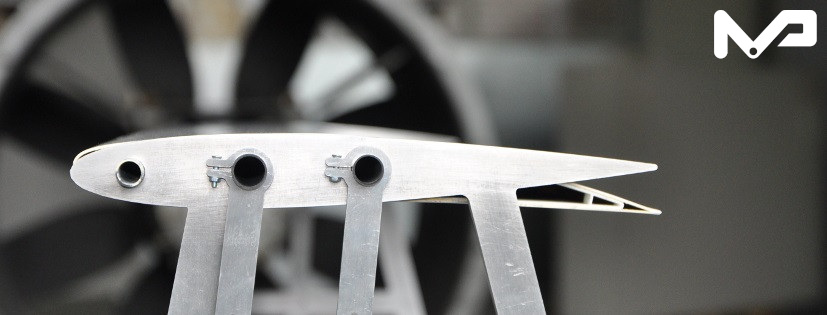

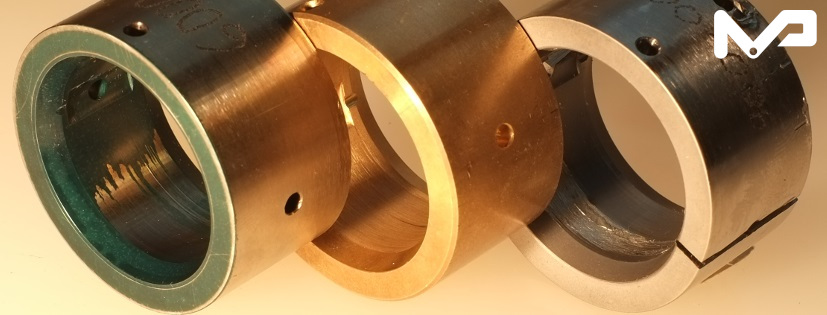

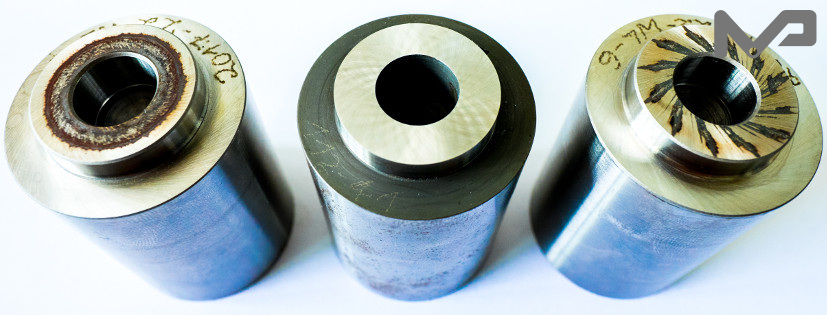

I would like to slowly bid farewell to the festive season. It is not without reason that my favourite machine elements accompany this greeting: the shaft-hub connection stands for strong cohesion, the plain bearing for stability and reliability, flexible mechanisms symbolise flexibility and creative approaches to solutions, the friction coefficient test specimen reminds us of the warmth we need during the cold season and finally the test specimen for the friction block test bench reflects the fascinating interplay of technical systems.

With these thoughts in mind, I wish you a peaceful Christmas season and a happy new year. I would like to express my sincere thanks for the excellent cooperation and look forward to joint projects and new ideas in the coming year.

IKAT Christmas Party 2025: Team Spirit, Creativity, and Enjoyment

On December 17, IKAT hosted its annual Christmas party. The event began with an exciting introduction to molecular gastronomy, providing a sweet source of motivation and a perfect start to the afternoon.

Afterwards, the staff faced three engaging challenges. The first was a bridge-building challenge, where participants were tasked with constructing a bridge using classic “construction materials” such as gingerbread dough, Mikado sticks, and icing. It quickly became clear that not all structures were able to withstand the required resistance to bending.

Once the unsteady bridges had been successfully overcome, the next challenge awaited: the so-called “Spazierngo.” This activity required creativity and technical insight, as typical mechanical engineering terms such as form fit, bearing, or topology optimization had to be captured visually in a natural environment.

A warming cup of mulled wine at the Chemnitz Christmas market marked the transition to the evening program. The group then enjoyed food and drinks at the restaurant “Betyár Csárda,” where the final challenge took place in the form of a quiz. The questions offered a concise and entertaining learning experience covering Erzgebirge culture, philosophy, and Christmas-related objects.

The event concluded with an award ceremony, during which the winners were honored with recognition, applause, and an additional treat.

We would like to thank Mr. Kanaparthy, Mr. Stahr, and Dr. Ahrens for the excellent organization of the Christmas party.

Evaluation of case-hardened components

Case hardening is a thermochemical surface hardening process which, through carburisation and subsequent hardening, produces a high-strength, wear- and fatigue-resistant surface layer with a tough core, and is therefore used in particular for highly stressed notched gear shafts and bearing seats.

In integral design concepts according to DIN 743 or FKM, the effective components of case hardening are reduced to a process-specific hardening influence (Kv), whereby the complexity of the process and the local stress are neglected and the prediction of long-term strength is subject to increased uncertainty, particularly in the case of notch and surface layer-dominated stresses.

In contrast, the differentiated approach of FKM (Section 5.5) and the FVA-guideline allow for the separate consideration of essential strength-relevant influencing factors such as hardness/strength gradients, surface layer-induced residual stresses and local stress states.

The aim of the ongoing research work is to systematically differentiate and quantify these partial effects of case hardening with regard to their contribution to long-term strength in order to increase the predictive accuracy of strength design.

Insight into practice – Advanced Manufacturing visits Kajamed

On 20 November, we visited Kajamed GmbH together with participants in the Applied Engineering Projects course, part of the Advanced Manufacturing degree programme. The students gained an insight into the manufacture of orthopaedic products. With the knowledge they acquired here, they are now in a position to develop innovative solutions for the problem specified by the company in their project. We would like to express our sincere thanks to Mr Körber for his support on the company side.