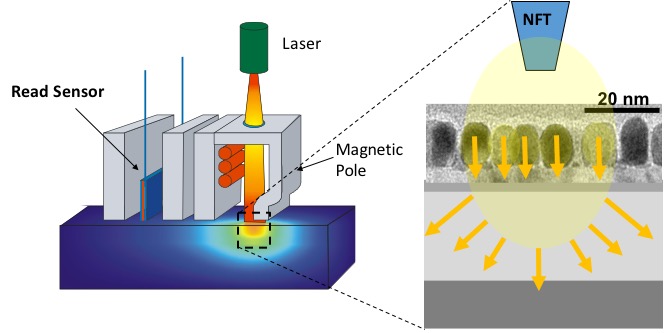

Heat Assisted Magnetic Recording (HAMR)

Heat Assisted Magnetic Recording (HAMR) is expected to be the next technology for increasing the areal density in Hard Disk Drive (HDD) systems [1-2]. In order to shrink bits and magnetic media grains further, currently used CoCrPt media layers in Perpendicular Magnetic Recording (PMR) will be replaced by very high anisotropy FePt L10 granular layers. In order to write such high anisotropy media an additional laser with plasmonic Near Field Transducer (NFT) is used to heat the media locally close to or above its Curie temperature TC during the nanosecond time scale write process, while long term media storage as well as read back occurs at room temperature.

References:

[1] B. C. Stipe, et al., Nature Photonics 4, (2010) 484 – 488.

[2] D. Weller, O. Mosendz, G. Parker, S. Pisana, and T. S. Santos, Phys. Status Solidi A 210, 1245 (2013).

[3] S. Pisana, S. Jain, J. W. Reiner, G. J. Parker, C. C. Poon, O. Hellwig, and B. C. Stipe, Appl. Phys. Lett. 104 (2014) 162407.

[4] S. Pisana, S. Jain, J. W. Reiner, O. Mosendz, G. J. Parker, M. Staffaroni, O. Hellwig, and B. C. Stipe, IEEE Trans. Magn. 51 (2015) 3200205.

[5] S. Wicht, V. Neu, L. Schultz, V. Mehta, S. Jain, J. Reiner, O. Mosendz, O. Hellwig, D. Weller, and B. Rellinghaus, J. Appl. Phys. 117 (2015) 013907.

[6] S. Wicht, S. H. Wee, O. Hellwig, V. Mehta, S. Jain, D. Weller, and B. Rellinghaus J. Appl. Phys. 119 (2016) 115301.