„3D-FAIM: Technologiefusion von 3D-FaserApplizieren und Spritzgießen (Injection Molding) zur Herstellung lastgerechter Leichtbaustrukturen“

Motivation

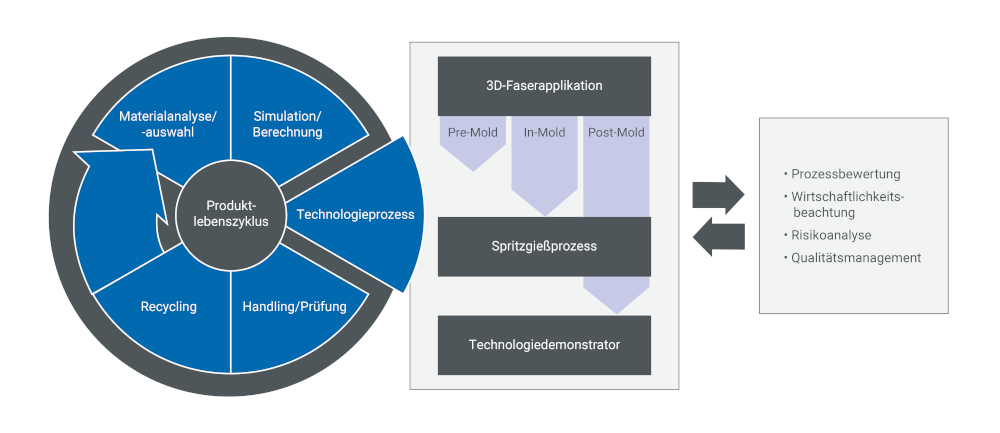

Die kundenindividuelle Großserienfertigung (sog. „Mass Customisation“) ist ein relevanter Aspekt des Leichtbaus, da sich nur durch eine individuelle lastgerechte Anpassung des Aufbaus von Leichtbaustrukturen weitere Materialeinsparungen erzielen lassen. Dies wird realisiert durch die Technologiefusion von:

-

Spritzgießen:Etabliertes Verfahren für die effiziente und kostengünstige Massenfertigung von Leichtbaustrukturen

-

3D-Faserapplizieren:Flexibilisierung und Individualisierung des Produktes, vor- und nachgelagert zur Spritzgießproduktion

Forschungsschwerpunkte

Es werden drei verschiedene Integrationsvarianten (hinsichtlich Effizienz, Robustheit und resultierender Bauteilqualität) betrachtet:

- Pre-Mold (Faserapplikation vor dem Spritzgießprozess)

- In-Mold (Faserapplikation im Spritzgießprozess)

- Post-Mold (Faserapplikation nach dem Spritzgießprozess)

Diese drei Varianten unterscheiden sich hinsichtlich des Zeitpunktes der Prozessfusion von 3D-Faserapplizieren und Spritzgießen.

Die technologische Innovation im Projekt stellt dabei die multifunktionale Lege- bzw. Drucktechnik (Ablegen endlosfaserverstärkter thermoplastisch imprägnierter Tapes sowie Drucken kurzfaserverstärkter Thermoplaste) dar, welche folgende Vorteile aufweist:

- neuartige Technologiekombination mittels 3D-Faserapplizieren für lokale Integration thermoplastischer Verstärkungsstrukturen in Spritzgießbauteile

- Großserienfähigkeit durch Nutzung von Synergieeffekten des Spritzgießens und 3D-Faserapplizierens

- Betrachtung des gesamten Produktlebenszyklus und damit Abbau von Markteintrittsbarrieren

Konsortium

Zur Umsetzung der ausgewählten Technologiefusion werden die komplementären Kompetenzen im Netzwerk genutzt. Das Projektkonsortium besteht aus fünf deutschen, zwei niederländischen und sechs polnischen Partnern.

|

|

|

|---|---|---|

| TU Chemnitz / Zentrale Einrichtung MERGE | Fachhochschule Saxion / TPAC | Technische Universität Wrocław / CAMT |

| KraussMaffei Technologies GmbH | CompTape B. V. | Technische Universität Bydgoszcz |

| Westfalia Presstechnik GmbH & Co. KG | Industriecluster Bydgoszcz | |

| FKT Formenbau und Kunststofftechnik GmbH | Technische Universität Oppeln | |

| R & R Automatisierungstechnik GmbH | Technische Universität Rzeszów | |

| Dopak SP. z o.o. |

Projektlaufzeit

09/2018 – 08/2021

Ansprechpartner

Motivation

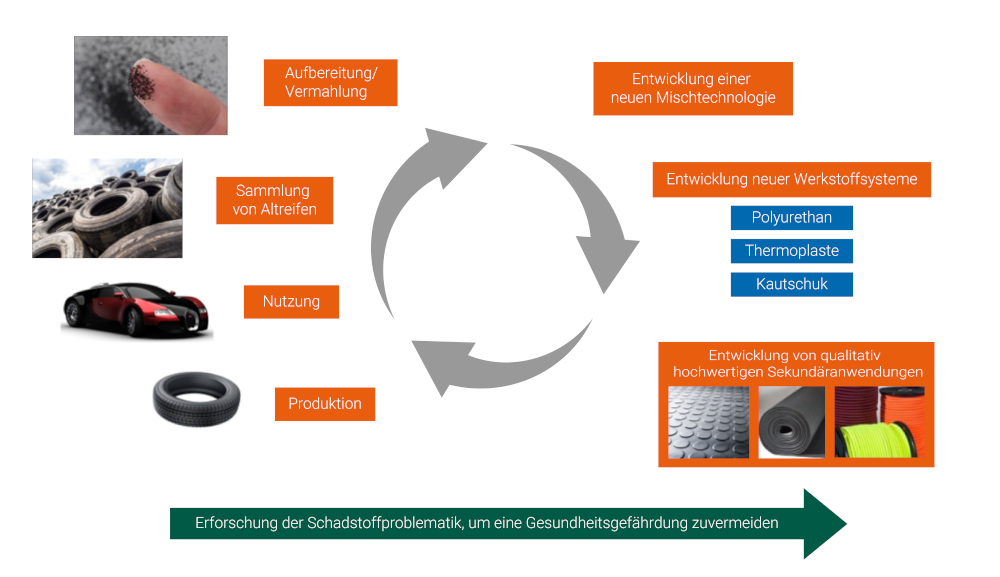

Das weltweite Altreifenaufkommen beträgt über 1,5 Mrd. Stück pro Jahr. In Zukunft wird die stoffliche Verwertung von Altreifen generell Vorrang vor der Verbrennung haben. Zunehmende rechtliche Verschärfungen in Deutschland und der EU erschweren den Marktzugang für Produkte aus Altreifenrezyklaten. Um in Zukunft durch die Einsparung von Ressourcen für Nachhaltigkeit und Wettbewerbsfähigkeit zu sorgen, werden in diesem Projekt technische, ökonomische und ökologische Randbedingungen für den Einsatz von Rezyklaten in neuen Werkstoffsystemen geschaffen.

Forschungsschwerpunkte

- Einsatz verschiedener Aufbereitungsverfahren, um Altreifen zu Gummifeinmehl zu vermahlen

- Umfassende chemische Untersuchungen in Bezug auf den Schadstoffgehalt in Gummifeinmehlen und Referenzprodukten

- Entwicklung neuer Verwertungskonzepte zur Ausweitung der Absatzmöglichkeiten für Altreifenrezyklate und neuer Werkstoffsysteme

- Realisierung einer zur großtechnischen Produktion geeigneten Mischtechnik für feine Gummimehle (Korngrößen < 0,4 mm) mit hohen Füllgraden (bis zu 70% Masseanteil)

- Entwicklung, Konstruktion und Umsetzung einer prototypischen Anlage zur Umsetzung der Mischtechnik

- Konzipierung einer Anlage zur großserienfähigen Produktion und Generierung neuer Absatzmöglichkeiten

Konsortium

Zur Entwicklung der neuen Mischtechnologie werden die komplementären Kompetenzen im Netzwerk genutzt.

Das Projektkonsortium besteht aus insgesamt sieben deutschen und vier polnischen Partnern.

|

|

|---|---|

| TU Chemnitz / Zentrale Einrichtung MERGE | Technische Universität Bydgoszcz |

| Fraunhofer IWU Chemnitz | Industriecluster Bydgoszcz |

| MRH Mülsen | Technische Universität Oppeln |

| ERMAFA Sondermaschinen- und Anlagenbau GmbH | Technische Universität Rzeszów |

| COVAC Elektro und Automation GmbH | |

| Estoma e. Kfm. | |

| PTO PolymerTechnik Ortrand GmbH |

Projektlaufzeit

01/2018 - 12/2019Ansprechpartnerin

-

Telefon:+49 371 531-30497

-

E-Mail:

-

Adresse:Reichenhainer Straße 31/33, 09126 Chemnitz

-

Raum:

StructureSens: Entwicklung eines strukturell integrierten Sensorsystems für faserverstärkte Kunststoffe auf Basis von technischen Fasern mit Metallbeschichtungen und Sensordrähten

Motivation

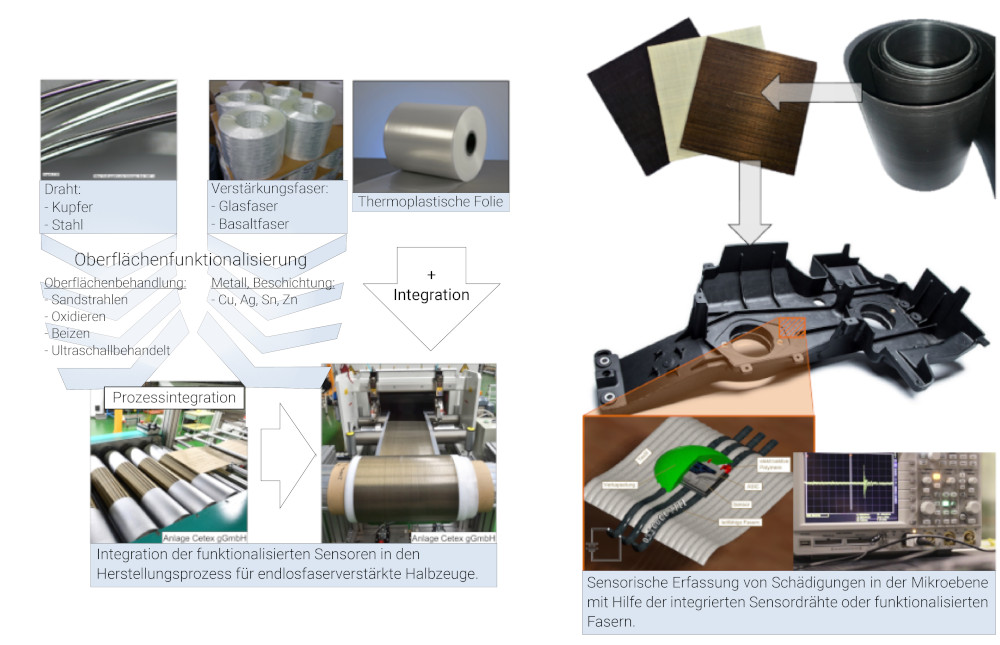

Faser-Kunststoff-Verbunde finden durch ihre hervorragenden Materialeigenschaften vermehrt Einsatz in Leichtbauanwendungen und im Automobilbau. Die faser-verstärkten Bauteile können im Einsatz potentielle Schwachstellen wie Risse und Delamination an der Grenzschicht zwischen Fasern und Matrix sowie weitere Schädigungen aufweisen. Diese sind von außen nicht sichtbar und breiten sich im Laminat bis zum Bauteilversagen aus. Das plötzliche Totalversagen des Bauteils soll durch eine neue In-situ-Überwachung frühzeitig erkannt und vermieden werden. Das neue System zum Strukturüberwachung des Bauteiles soll kostengünstig sein und in die großserientauglichen Herstellungsprozesse für endlosfaserverstärkte Halbzeuge integriert werden.

Forschungsschwerpunkte

Ziel des Vorhabens ist die Integration von bauteilgerechten Sensoreinlegern (funktionalisierte Fasern und Sensordrähte) in endlosfaserverstärkten Bauteilen zur Strukturüberwachung und Funktionalisierung. Zur Realisierung soll ein Sensorprinzip auf der Basis von leitfähigen metallischen Beschichtungen für technische Fasern entwickelt und umgesetzt werden. Die Grundlage des angestrebten Sensorsystems zur Strukturüberwachung und Funktionalisierung von Faser-Kunststoff-Verbunden bilden die beschichteten Glasfaserrovings und Sensordrähte. Die funktionalisierten Sensoren nutzen die inhärenten Materialeigenschaften der elektrischen Leitfähigkeit der Sensoreinleger aus. Durch die Messung des elektrischen Widerstandes können mechanische Verformungen erfasst und zusätzliche Sensorfunktionen in das Bauteil integriert werden.

Die Vorteile gegenüber aktueller Struktur-Überwachungssysteme sind:

- Struktur- und prozessintegrierte Funktionalisierung

- Anwendung für thermoplastische und duroplastische Matrixsysteme

- Strukturüberwachung zur Schadensdetektion

- Adaptive Strukturen des Sensoreinlegers für den Anwendungsfall

Konsortium

Die Umsetzung dieser neuen Sensorsysteme erfordert die Bündelung komplementärer Kompetenzen im Netzwerk. Das Projektkonsortium besteht aus drei deutschen, drei polnischen und zwei tschechischen Partnern.

|

|

|

|---|---|---|

| TU Chemnitz / Zentrale Einrichtung MERGE | Technische Universität Wrocław | Technische Universität Liberec |

| Hugo Stiehl GmbH Kunststoffverarbeitung | Technische Universität Oppeln | Vecernik Ltd. |

| Santenberg Maschinen Deutschland GmbH | Dopak SP. z o.o. |

Projektlaufzeit

01/2019 – 12/2020

Ansprechpartner