News

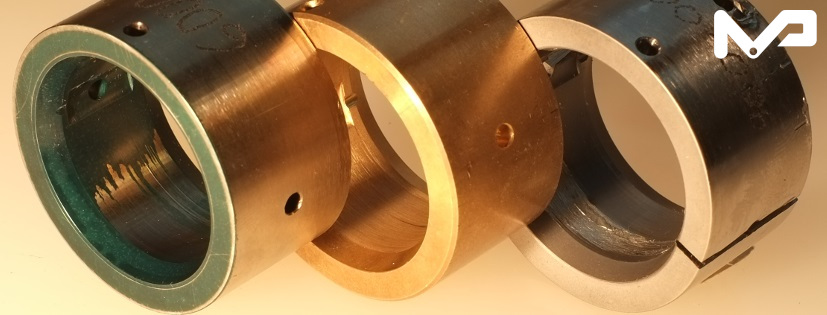

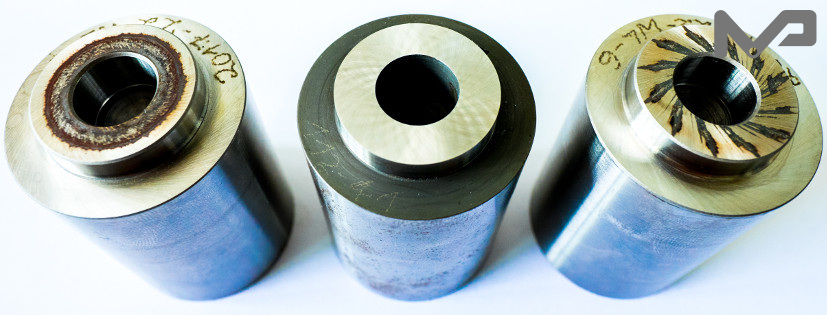

PA AK shaft-hub-connections @Clausthal University of Technology

From May 16-17, the WNV/strength section presented its research results at the PA AK WNV at TU Clausthal. In the domed building of the Aula Academica, topics of frictional and positive shaft-hub connections in particular were discussed and debated. The transfer of research into practice is an important function of the PA AK WNV, which is why many representatives from industry were present in addition to representatives from research institutes from all over Germany. We would like to thank the FVA and IMW for the constructive exchange and the excellent organization of the event.

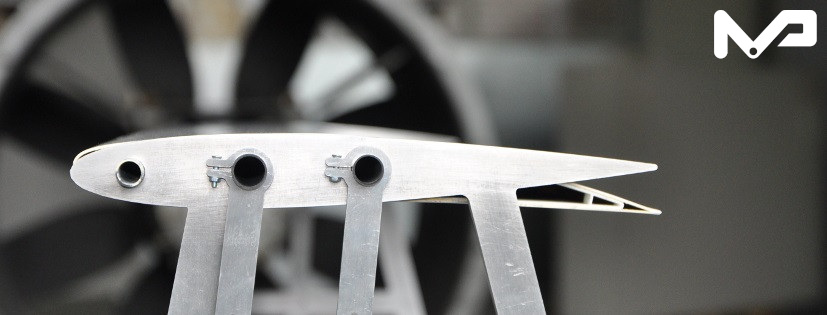

Presentation of the projet Sensor-Integrating feather key at DMK 2024

The Dresdener Maschinenlemente Kolloquium took place from 14-15 May. IKAT – represented by Mr Muhammedi – presented the current status of the project „Sensor-integrated feather key„. We would like to thank you for the discussions and the exciting input during the conference. We look forward to the DMK 2026.

Sustainable Products

Up to now, technical products have often been assessed for their full sustainability spectrum only after they have been developed. In the case of revolutionary products and disruptive developments, there is no generational development, so there is no information on the sustainability of previous generations. In the absence of information on previous generations, the assessment can only be a rough guide due to a lack of information, and will become more precise as more information on the product becomes available during product development. In this way it is possible to assess the sustainability of any product, regardless of its history. In addition, the knowledge gained from the previous product can be used through appropriate documentation.