VP 3.1 AgilPlanBZ

Agile factory planning in the highly dynamic market and development environment of fuel cell production

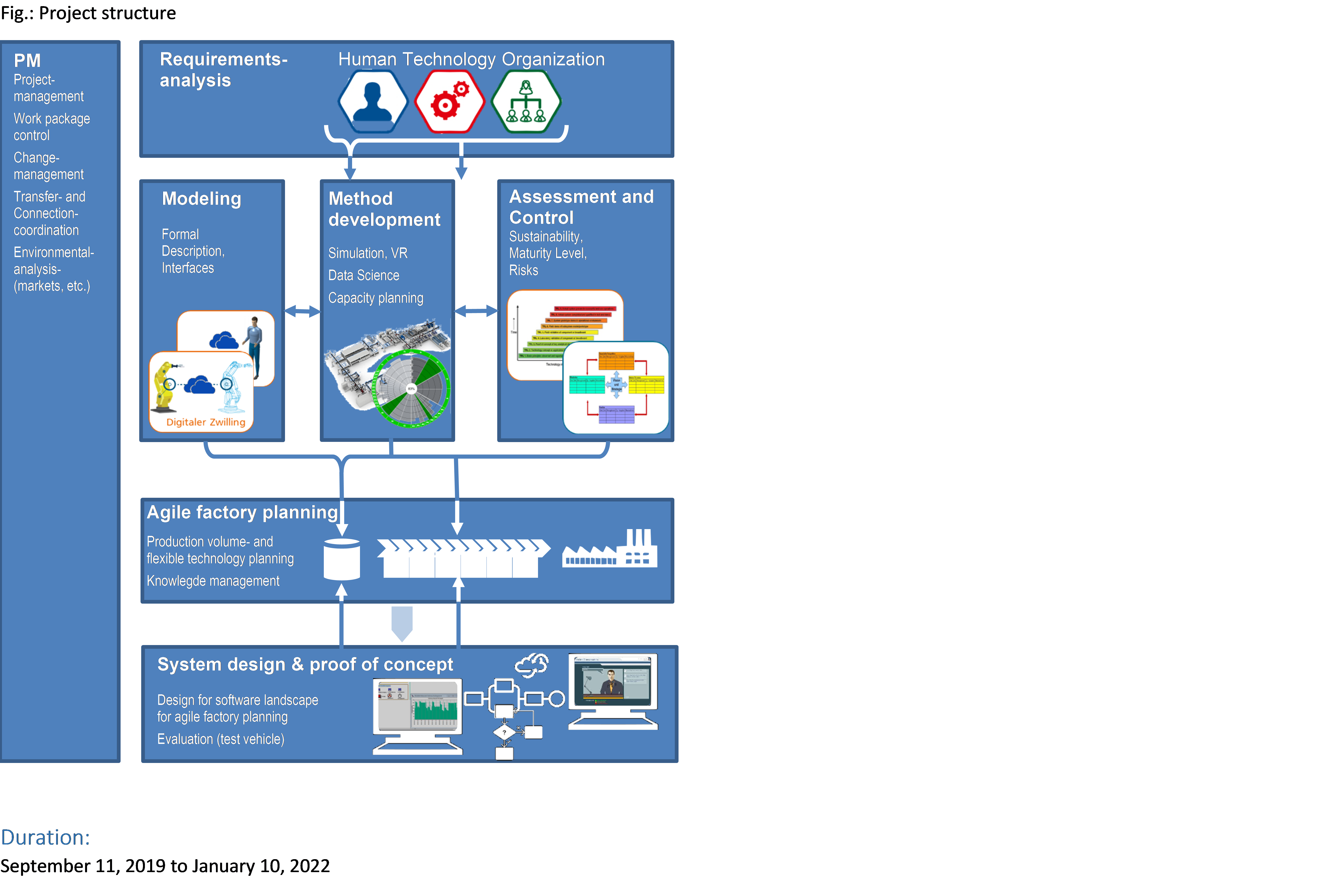

In the project, agile project management methods are to be used to develop a proactive factory planning procedure that enables short-cycle planning of production systems and processes with high volatility and uncertainty in the input conditions and which can be scaled to a large extent.

As with any other planning and management task, there are economic, social and ecological sustainability aspects to be address during factory planning as well. Therefor the tasks of the chair of Management Accounting and Control within the scope of this project is to deliver instruments for assessing and managing sustainability aspects of different alternatives for fuel cell production systems. As a result of the early phase of the market and the underlying technology, corresponding assessment/management tools must be able to deal with uncertainty as well as risks.

Objectives:

- Development of a system for digital modeling and system design in agile processes, based on the approach of the digital twin

- Development of a planning-integrated evaluation method for maturity, risk, flexibility, sustainability and versatility of production systems

- Design of a software prototype to support agile factory planning processes

Funding and project management

ESF-EFRE Technologieförderung, SAB Sächsische Aufbaubank

Partner:

Fuel Cell Powertrain GmbH, Fraunhofer-Institut für Werkzeugmaschinen und Umformtechnik, Hörmann Rawema Engineering & Consulting GmbH, SimPlan AG, Technische Universität Chemnitz

Diese Maßnahme wird mitfinanziert durch Steuermittel auf Grundlage des von den Abgeordneten des Sächsischen Landtags beschlossenen Haushaltes.