Textile Innovation for Bicycles

A team of founders at the TU Chemnitz want to make bicycles even lighter with spokes made from high-tech fibers

-

The founding team from the TU Chemnitz: the four junior researchers Ingo Berbig (l.), Daniela Storch, Stephanie Mager and Dirk Fischer want to make bicycles even lighter with spokes made from high-tech fibers. Photo: TU Chemnitz/Wolfgang Thieme -

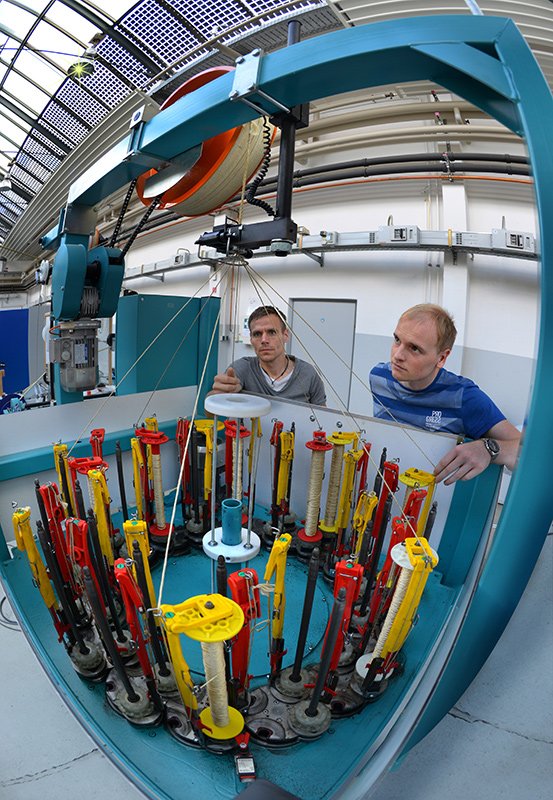

Dirk Fischer (l.) and Ingo Berbig prepare a test machine to conduct a tensile test of a high-tech fiber rope. Photo: TU Chemnitz/Wolfgang Thieme -

Daniela Storch inspects the alignment of a wheel which has been outfitted with textile spokes, with the help of a truing stand. Photo: TU Chemnitz/Wolfgang Thieme -

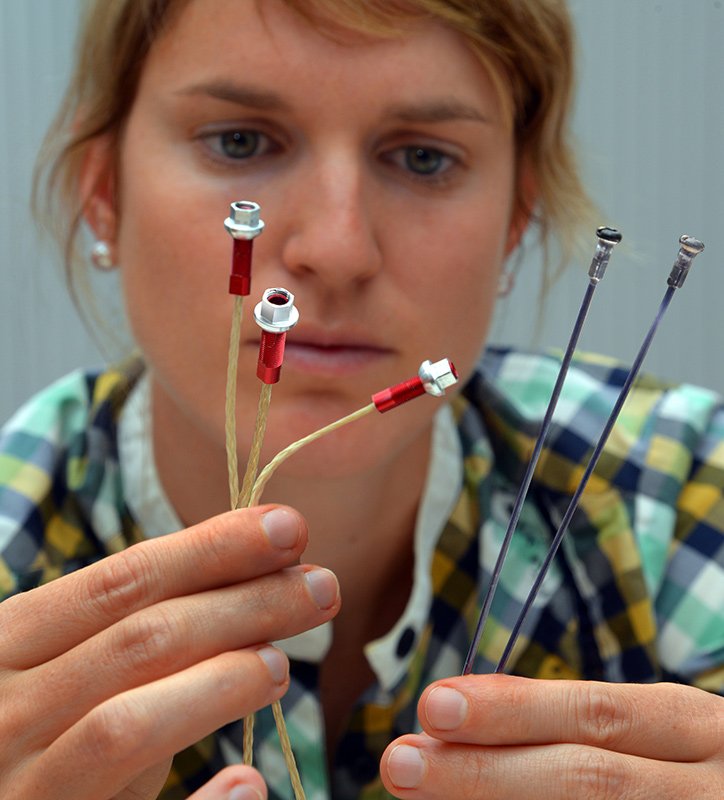

The textile bicycle spokes are more than 50 percent lighter than traditional spokes made of steel. Photo: TU Chemnitz/Wolfgang Thieme -

Ingo Berbig (l.) and Dirk Fischer prepare a braiding machine for the production of textile spokes made from high-tech fibers. Photo: TU Chemnitz/Wolfgang Thieme

With spokes made from synthetic fibers, bicycles can become even more lightweight. Four junior researchers at the Technische Universität Chemnitz hope to enter the market with this business concept. The textile spokes are being developed in the research laboratories of the Department of Mechanical Engineering by the Professorship of Materials Handling and Conveying Engineering.

While conventional bicycle spokes are made from stainless steel, aluminum or even carbon in the professional realm, researchers in Chemnitz are betting on synthetic high-strength high-tech fibers, which have a substantial advantage: they are very lightweight. “In terms of the spokes, we can reduce the weight by more than 50 percent, which is comparable to carbon,” says Ingo Berbig, research associate at the Professorship. His colleague Daniele Storch, also a member of the founding team, knows how important this aspect can be, as she is an experienced mountain biker. “In competitions, I have to maneuver my eight or nine kilogram bike over really rough terrain. In these situations, I would even welcome a weight reduction of just 100 grams,” explains the internationally successful athlete. “On hills, each gram matters both for hobbyists and professional athletes,” says Berbig, who is himself a passionate cyclist and coaches a group of youth cyclists at the Radsportverein Chemnitz.

The textile spokes, whose exact composition is kept confidential, have already successfully passed a 100,000 kilometer endurance trial. “Around the clock, the thin spokes were subjected to strain which simulates impact with obstacles,” reports Berbig. Additionally, countless tensile tests have been conducted on the fiber ropes. In summary: the textile spokes are extremely durable and efficient. “From an economic perspective, it has been shown that the new kinds of wheels from Chemnitz that rely on textile spokes are competitive against other types of wheels of similar performance categories,” according to TU graduate Stephanie Mager, who contributes her know-how from her studies at the Faculty of Economics and Business Administration to the founding team.

While working on his master thesis at the Professorship of Materials Handling and Conveying Engineering, Dirk Fischer developed the individual components of the wheels. “We were able to configure an individually compatible wheelset for each cyclist according to his own user profile as regards acceleration, damping behavior, weight, design, etc.,” says Fischer. This is primarily ensured by the ability to configure the moment of inertia by specially selecting the components. An innovative spoke-concept also guarantees additional weight reduction in the wheel hub.

The researchers, who aim to establish a startup enterprise based on their research results, have access to 95,000 euros in funding for this purpose through the “EXIST-Gründerstipendium” support program, which receives support from the European Social Fund and the Federal Ministry for Economic Affairs and Energy. They now have one year to create a business plan and prepare their innovative spoke system for serial production. A patent application has already been filed. The spokes should be made available to hobby cyclists, professionals and E-bike drivers. As they make the leap toward independence and self-sufficiency, the TU Chemnitz will be supported by the Professorship of Materials Handling and Conveying Engineering and the SAXEED founder network. “Results of our InnoProfile-Transfer project also have an influence on the start-up projects, for example the understanding of the relationships between high-performance fiber ropes and the adjoining machine elements,” explains Prof. Dr. Klaus Nendel, who leads the Professorship of Materials Handling and Conveying Engineering.

At the moment, the Chemnitz-based junior researchers are planning a fatigue test and further practically relevant endurance tests. “This way, we can guarantee the quality of our product,” says Storch. Parallel to this, test drives are conducted in both street and off-road settings. Since September 12, a prototype bicycle equipped with the new spoke system is available to view in the special “The Bicycle” exhibition at the Chemnitz Museum of Industry. “Touching is expressly permitted,” says Storch.

More information are available from Ingo Berbig, Telephone 0049 371 531-36460, E-Mail ingo.berbig@mb.tu-chemnitz.de, and Daniela Storch, Telephone 0049 371 531-36189, daniela.storch@mb.tu-chemnitz.de

(Translation: Sarah Wilson)

Mario Steinebach

23.09.2016