The Chemnitz University of Technology presents a globally unique pilot plant for sustainable lightweight construction

Winding principle reversed: The Orbital Wrapping process is about to set new standards in the large-scale production of complex fiber reinforced profiles

-

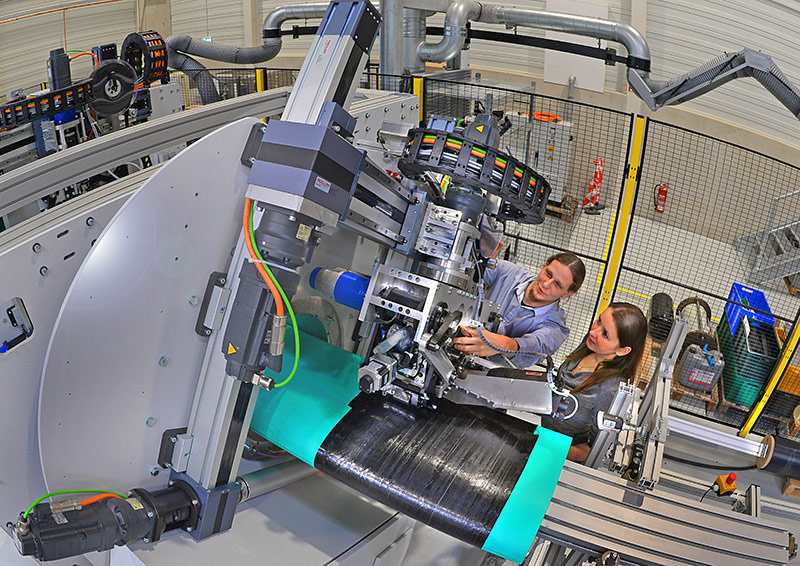

Research Associates of the Federal Cluster of Excellence MERGE and the Institute of Lightweight Structures of the Chemnitz University of Technology Rainer Wallasch and Agnieszka Kalinowska during the testing of the globally unique pilot plant for the orbital wrapping process for the production of complex structural fiber reinforced components, for example, rotor blades of small wind turbines. Photo: TU Chemnitz/ Wolfgang Thieme

Academic researchers of the Federal Cluster of Excellence MERGE EXC 1075 “MERGE Technologies for Multifunctional Lightweight Structures” and the Institute of Lightweight Structures at the Chemnitz University of Technology developed a novel technology for the fabrication of closed, endless fiber-reinforced profiles, such as structural shapes with varying forms. In comparison to the classical thermoplastic tape winding, not rotation-symmetric components can now be produced continuously with the so-called Continuous Orbital Wrapping Process (short COW). In the MERGE Technology Center located on the Campus of the Chemnitz University, feasibility and technology studies are currently conducted for the optimal setting of the production process in the pilot plant. The globally unique technology was first introduced to the public on April 27, 2017.

The project aims to investigate a process chain in which complex structural components such as load suitable structural shapes for automotive applications or parts for small wind turbine rotor blades can be manufactured in large-scale production. Despite the very special cross-sections of these components, material- and cost-efficient manufacturing is made possible due to the Chemnitz technology. Those fiber-reinforced structural shapes and pipes are especially of importance as supporting structures or components. Different kinds of fiber-reinforced tapes are currently in the trial period for the manufacturing process. The materials are investigated according to their processability into high-performance components.

“Technologies such as the orbital wrapping process are especially in the field of vehicle construction but also in the mechanical and plant engineering of high demand. Thus, I am convinced that the Federal Cluster of Excellence MERGE paves the way with this novel winding process and the findings obtained from the fundamental research for multifunctional and sustainable lightweight applications in the future – worldwide”, explains Prof. Lothar Kroll, coordinator of the Federal Cluster of Excellence MERGE.

Winding principle reversed

The researchers of the Federal Cluster of Excellence MERGE have been looking for a way to integrate the principle into an overarching value chain in order to effectively link up – and downstream processes. This way, shapes with variable concave or convex transverse sections can be produced continuously and large-scale suitable. The fundamental solution: “Inside the plant, the laying head of each winding unit rotates around its core, reversing the winding process”, illustrates Rainer Wallasch, research associate in the Federal Cluster of Excellence MERGE, the special feature of the process.

The continuous, linear feed-through of the winding mandrel through several orbital winding units of the plant allows the large-scale production of almost endless semi-finished products with varying winding angles. Each orbital winding unit is equipped with a laying head, the so-called depositing device for the thermoplastic tape. This head then rotates around the core. “The tape is then placed in a way to create the required cross-section. The core is continuously driven through the winding units, theoretically endless”, explains Wallasch. Basis is a complex algorithm with relevant mechanical and controlling implementation that can kinematical navigate the laying heads around the winding core. This process is to be applicable for all component shapes in the future.

The principle of the classic thermoplastic-tape winding is an already established technology in the field of composite processing, which was further developed in the course of the Federal Cluster of Excellence MERGE to the Continuous Orbital Wrapping Process (COW). The conventional winding process is characterized by a tape wound around a core due to the cores’ rotational movement. The tape – usually a unidirectional fiber-reinforced thermoplastic tape – is pulled off a braked coil, heated, fused and by the retraction force of the tape added to the previously wound layer during the cooling process. This generally produces a rotation-symmetric profile.

Background information: Federal Cluster of Excellence MERGE

In this nationwide unique project approx. 100 academic researchers and technicians work on the technology fusion of multifunctional lightweight structures since 2012. Main aim is the merging of currently separated production processes during the processing of different material groups such as textiles, plastics and metal and to equip them with sensor and actuator technology. This would lead to a more cost- and energy-efficient large-scale production of multicomponent parts. Within the Federal Cluster of Excellence numerous small and medium-size businesses are involved, complementarily reflecting the value chain “Vom Werkstoff zur Leichtbaustruktur”. The project results of the Cluster supply the leading markets of automobile industry, aerospace, mechanical engineering and microsystems technology.

Homepage of the Federal Cluster of Excellence MERGE: https://www.tu-chemnitz.de/MERGE

Further information are available from Prof. Lothar Kroll, phone +49 371 531 23120, email lothar.kroll@mb.tu-chemnitz.de and Jürgen Tröltzsch, MERGE Scientific Director, phone +49 371 531 35665, email juergen.troeltzsch@mb.tu-chemnitz.de

(Translation: Alissa Hölzel)

Mario Steinebach

09.05.2017